Parameter Description Unit

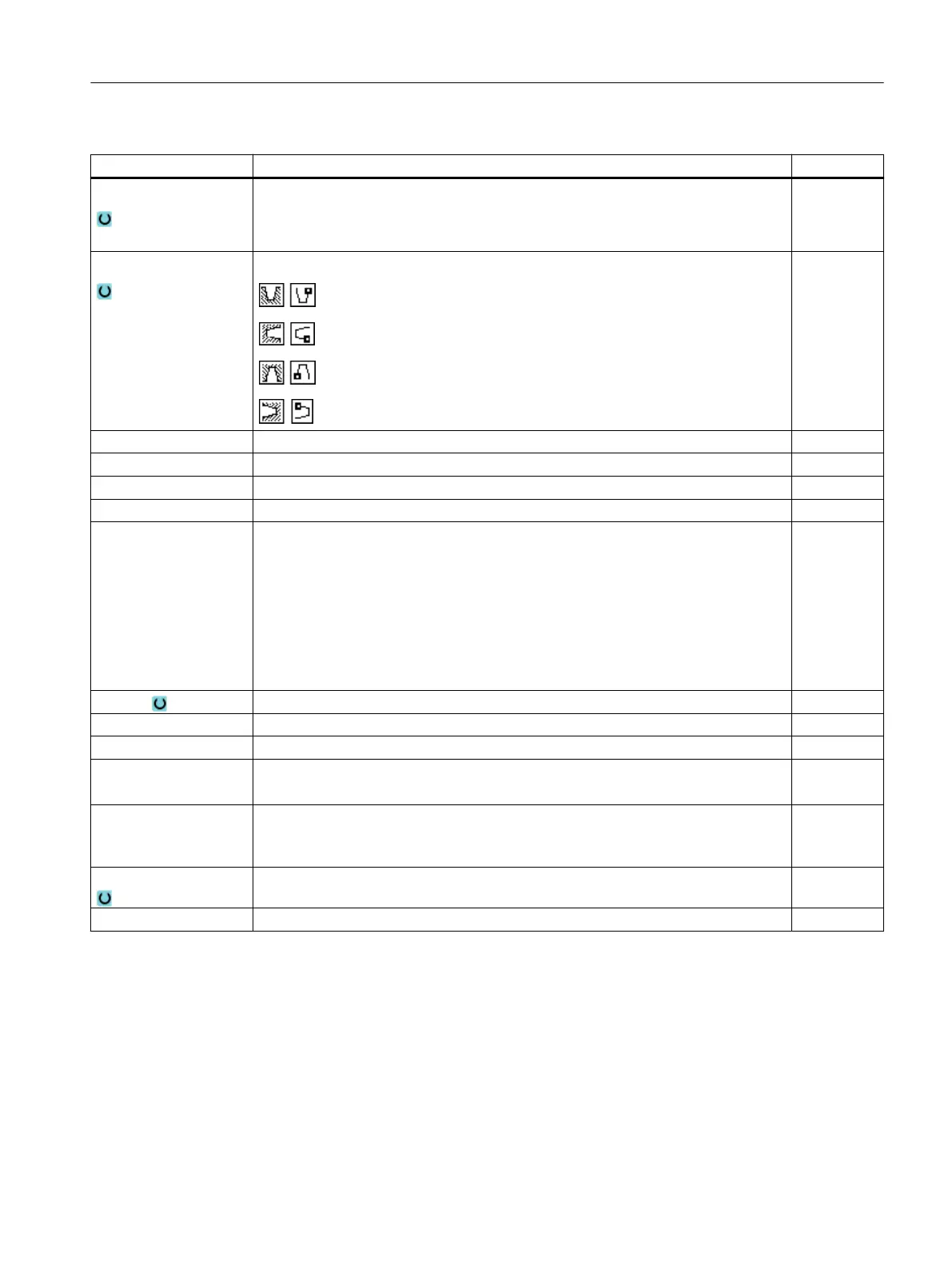

Machining

● ∇ (roughing)

● ∇∇∇ (finishing)

● ∇ + ∇∇∇ (roughing and finishing)

Position Groove position:

X0 Reference point in X ∅ mm

Z0 Reference point in Z mm

B1 Groove width mm

T1 Groove depth ∅ (abs) or groove depth referred to X0 or Z0 (inc) mm

D

● Maximum depth infeed for insertion – (only for ∇ and ∇ + ∇∇∇)

● For zero: Insertion in a cut – (only for ∇ and ∇ + ∇∇∇)

D = 0: 1. cut is made directly to final depth T1

D > 0: 1st and 2nd cuts are made alternately to infeed depth D, in order to achieve

a better chip flow and prevent the tool from breaking, refer to approaching/retraction

when roughing.

Alternate cutting is not possible if the tool can only reach the groove base at one

position.

mm

UX or U Finishing allowance in X or finishing allowance in X and Z – (only for ∇ and ∇ + ∇∇∇) mm

UZ Finishing allowance in Z – (for UX, only for ∇ and ∇ + ∇∇∇) mm

N Number of grooves (N = 1....65535)

DP Distance between grooves (inc)

DP is not displayed when N = 1

mm

α1, α2 Flank angle 1 or flank angle 2 - (only for grooves 2 and 3)

Asymmetric grooves can be described by separate angles. The angles can be be‐

tween 0 and < 90°.

Degrees

FS1...FS4 or R1...R4 Chamfer width (FS1...FS4) or rounding radius (R1...R4) - (only for grooves 2 and 3) mm

α0 Angle of the incline – (only for groove 3) Degrees

* Unit of feedrate as programmed before the cycle call

Programming technology functions (cycles)

10.2 Rotate

Turning

Operating Manual, 06/2019, A5E44903486B AB 411

Loading...

Loading...