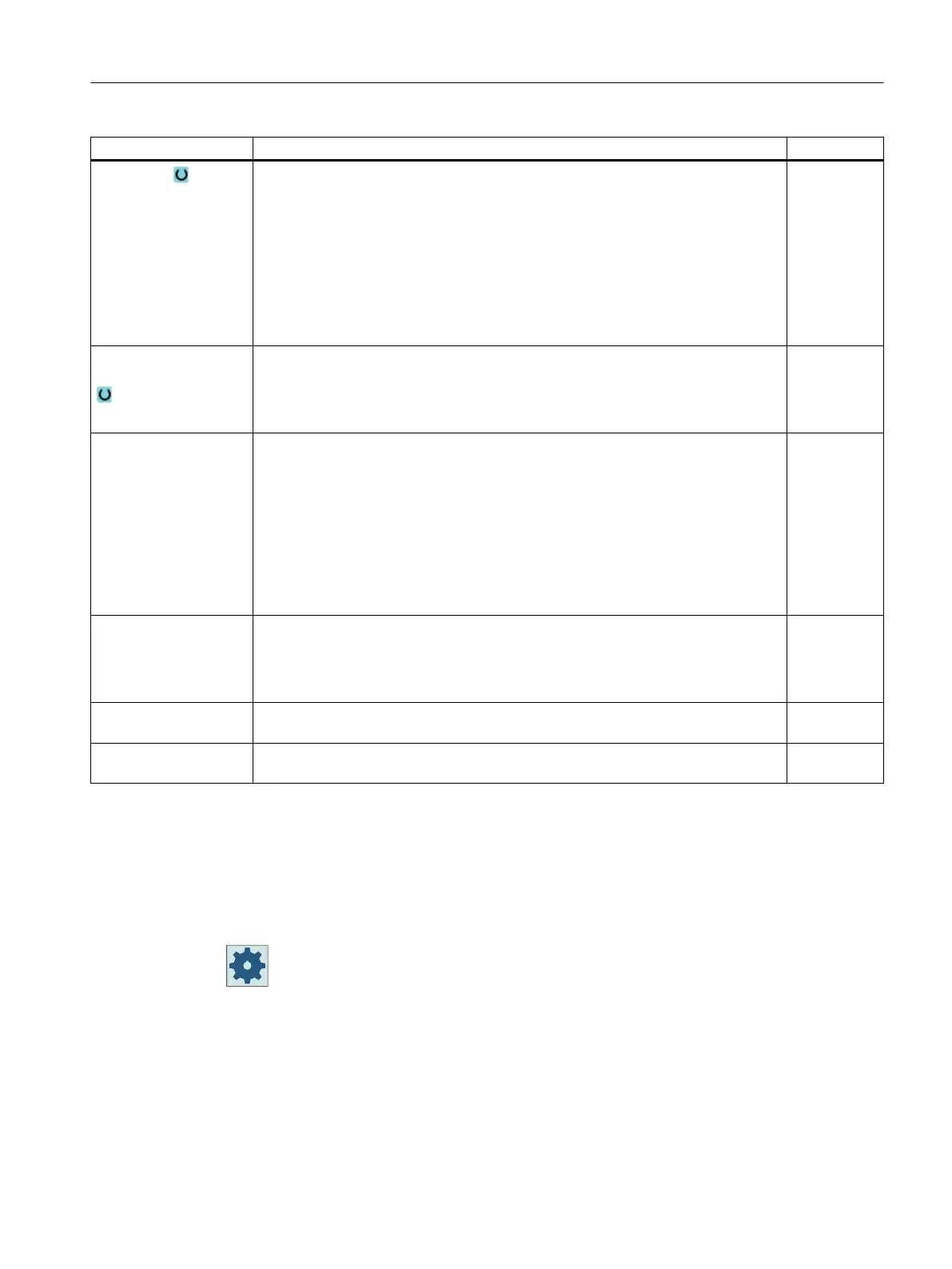

Parameter Description Unit

Work offset Work offset in which the coordinate system, which was shifted according to ZW and

by ZV as well as mirrored in Z, must be saved:

● Basic reference

● G54

● G55

● G56

● G57

● ...

Write to the

work offset

● Yes

The Z value of the work offset can be directly written to the input screen form.

● No

The actual Z value of the work offset is used.

ZV - only for work offset

write "yes"

● Offset Z = 0 (abs)

● Workpiece zero is offset in Z direction (inc, the sign is also evaluated)

The parameter is used to ensure that the correct display is shown in the

simulation. It has no influence on machining itself.

The workpiece is re-clamped when switching between the main spindle and

counterspindle. The new work offset defines the position for machining at the

machine. However, the simulation must know by which amount the work offset

has shifted with respect to the workpiece, so that both sides of the machining can

be displayed.

mm

mm

Park counter-spindle -

for machining with main

spindle

● Yes

The counter-spindle is traversed to the park position.

● No

The counter-spindle is not traversed.

Z4P - for machining

with main spindle

Park position of the counter-spindle (abs); MCS mm

Z4W - for machining

with counter-spindle

Machining position of the counter-spindle (abs); MCS mm

10.7.18 Machining with fixed counterspindle

If your lathe is equipped with a second spindle, which is setup as a counterspindle and cannot

be traversed, then the workpieces must be manually reclamped

Machine manufacturer

Please refer to the machine manufacturer's specifications.

Machining with main spindle and counterspindle

For instance, a new blank can be clamped in the main spindle, and a blank that has already

been machined at the front can be clamped in the counterspindle. With the ShopTurn program,

Programming technology functions (cycles)

10.7 Additional cycles and functions in ShopTurn

Turning

Operating Manual, 06/2019, A5E44903486B AB 657

Loading...

Loading...