10.6.2.2 Aligning milling tools - only for G code program (CYCLE800)

Procedure

1. The part program to be executed has been created and you are in the

editor.

2. Press the "Various" softkey.

3. Press the "Swivel tool" and "Align milling tool" softkeys.

The "Align milling tool" input window opens.

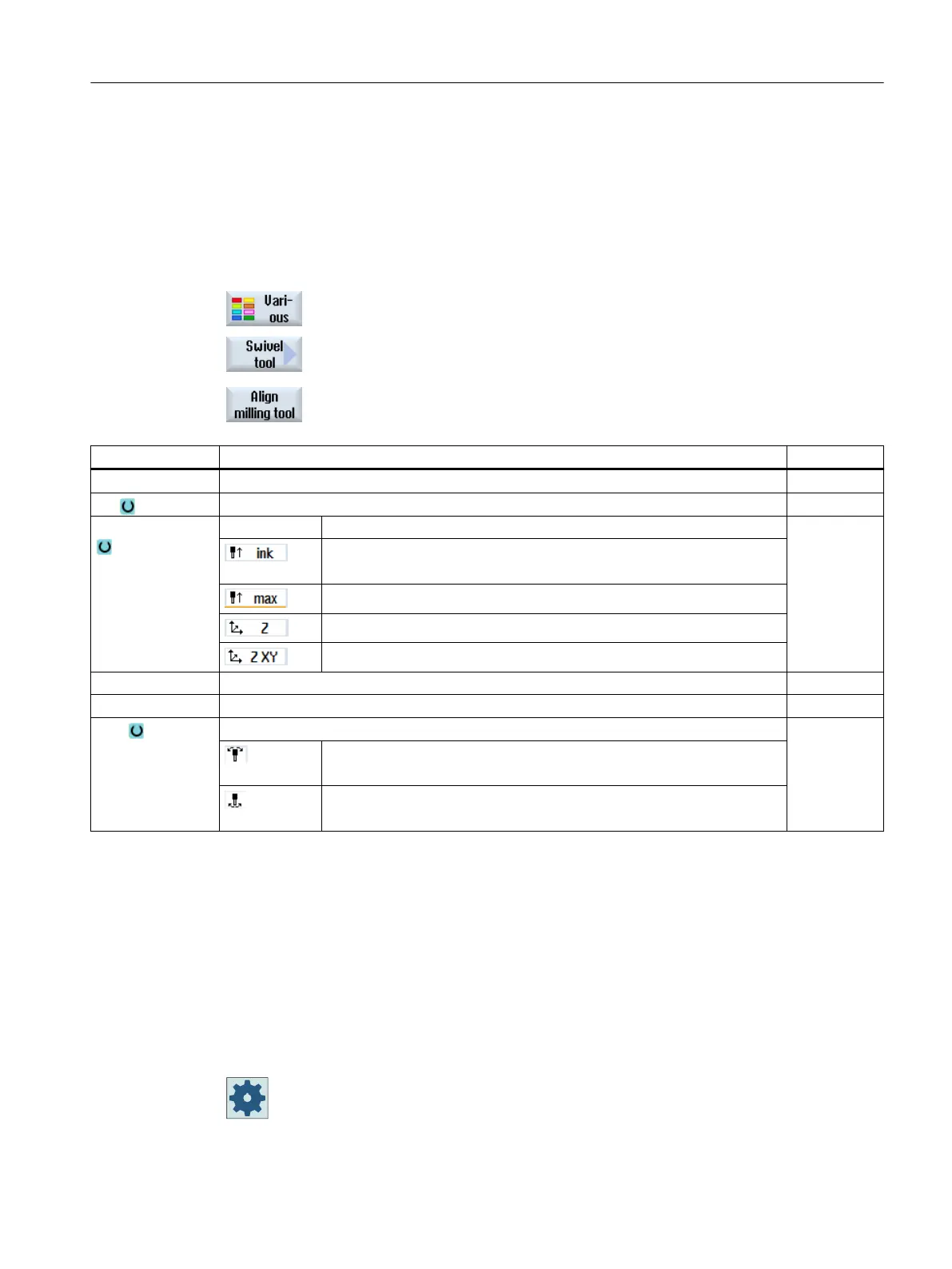

Parameter Description Unit

PL Plane for milling

TC Name of the swivel data record

Retraction No No retraction before swiveling

Incremental retraction in tool direction

The retraction path is entered into parameter ZR.

Maximum retraction in tool direction

Retraction in the direction of machine axis Z

Retract towards the machine axis Z and then in the direction X, Y

ZR Retraction path - (only for incremental retraction in the tool direction)

β Rotation around the 3rd geometry axis (for G18 Y) Degrees

Tool Tool tip position when swiveling

Tracking

The position of the tool tip is maintained during swiveling.

No tracking

The position of the tool tip changes during swiveling.

10.6.2.3 Preloading milling tools - only for G code program (CYCLE800)

After "Swivel plane", the tool orientation is always perpendicular on the machining plane. When

milling with radial cutters, it can make technological sense to set the tool at an angle to the

normal surface vector. In the swivel cycle, the setting angle is generated by an axis rotation

(max. +/- 90 degrees) to the active swivel plane. When setting, the swivel plane is always

“additive”. With "Setting tool", only rotations are displayed on the swivel cycle input screen form.

The user can freely select the rotation sequence.

Machine manufacturer

Please refer to the machine manufacturer's specifications.

Programming technology functions (cycles)

10.6 Further cycles and functions

Turning

Operating Manual, 06/2019, A5E44903486B AB 615

Loading...

Loading...