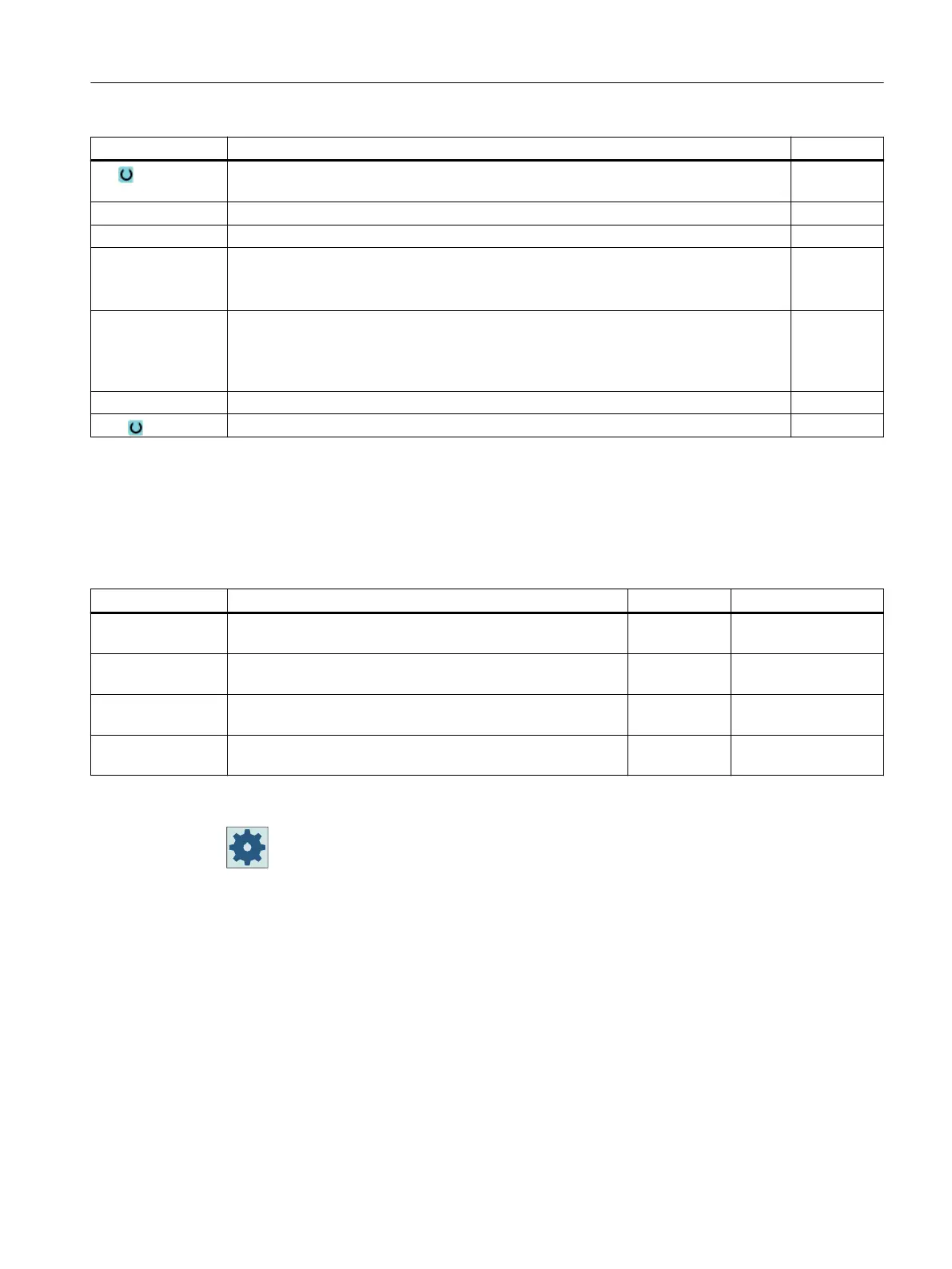

Parameter Description

FZ (only for

ShopTurn)

Depth infeed rate – (only for vertical insertion and ∇) mm/min

mm/tooth

FZ (only for G code) Depth infeed rate – (only for vertical insertion and ∇) *

EP Maximum pitch of helix – (for helical insertion only) mm/rev

ER Radius of helix – (for helical insertion only)

The radius cannot be any larger than the milling cutter radius; otherwise, material will

remain.

mm

EW Note:

During insertion with oscillation, the message “Ramp path too short” will appear if the tool

is less than the milling cutter diameter away from the insertion point along the ramp. If this

occurs, please reduce the angle of insertion.

Degrees

FS Chamfer width for chamfering (inc) - (for chamfering only) mm

ZFS Insertion depth of tool tip (abs or inc) - (for chamfering only) mm

* Unit of feedrate as programmed before the cycle call

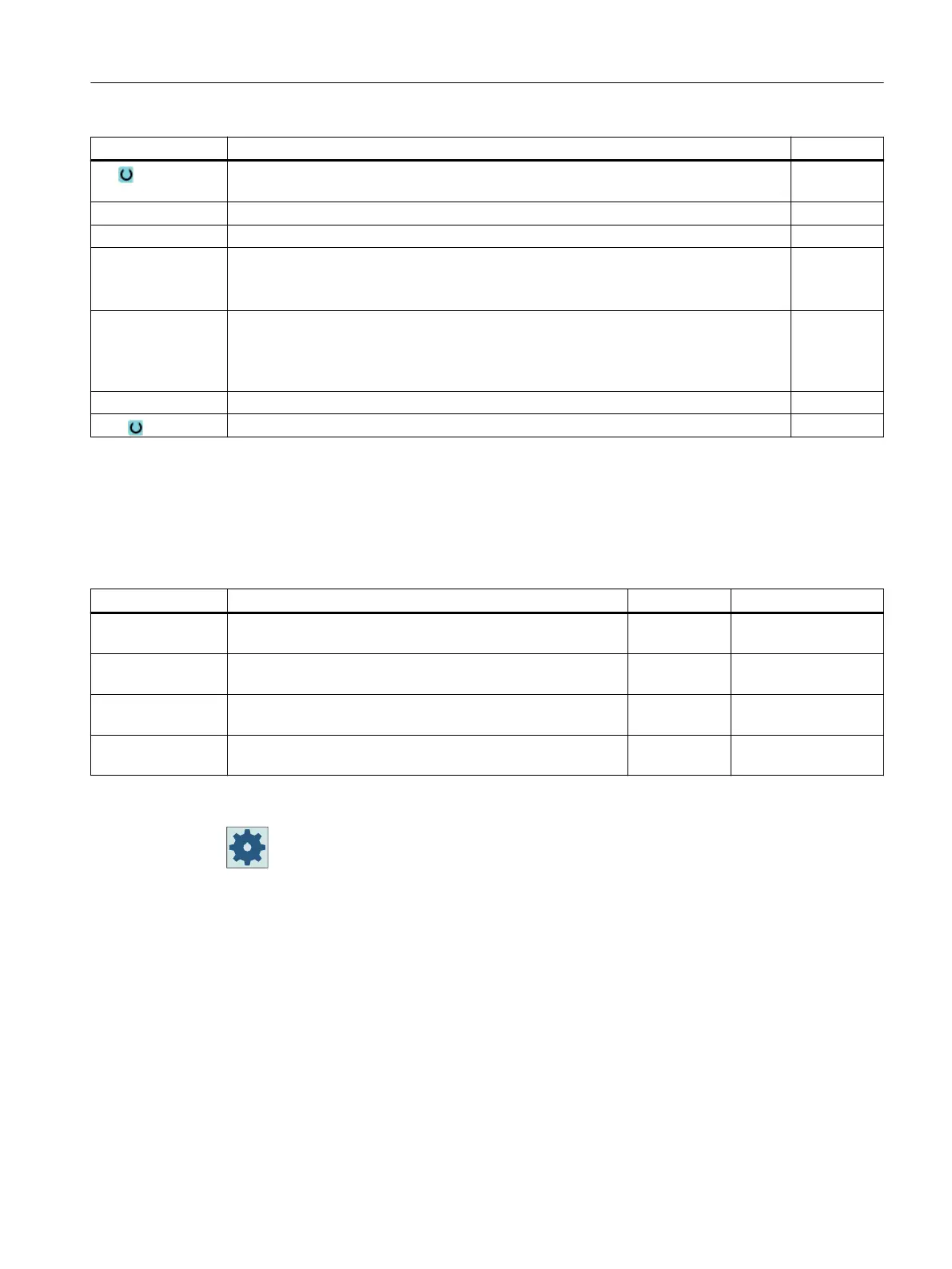

Hidden parameters

The following parameters are hidden. They are pre-assigned fixed values or values that can be

adjusted using setting data.

Parameter Description Value Can be set in SD

PL (only for G code) Machining plane Defined in MD

52005

SC (only for G

code)

Safety clearance 1 mm x

Starting point Starting point is automatically calculated - (only for ∇ and ∇∇∇

base)

Automatic

Lift mode Lift mode before new infeed - (only for ∇, ∇∇∇ base or ∇∇∇

edge)

to RP

Machine manufacturer

Please refer to the machine manufacturer's specifications.

10.5.11 Contour pocket residual material (CYCLE63, option)

Function

When you have removed stock from a pocket (with/without islands) and there is residual

material, then this is automatically detected. You can use a suitable tool to remove this residual

material without having to machine the whole pocket again, i.e. avoiding unnecessary non-

productive motion. The finishing allowance should be set identically for all machining steps

because it does not count as residual material.

Programming technology functions (cycles)

10.5 Contour milling

Turning

Operating Manual, 06/2019, A5E44903486B AB 593

Loading...

Loading...