Hidden parameters

The following parameters are hidden. They are pre-assigned fixed values or values that can be

adjusted using setting data.

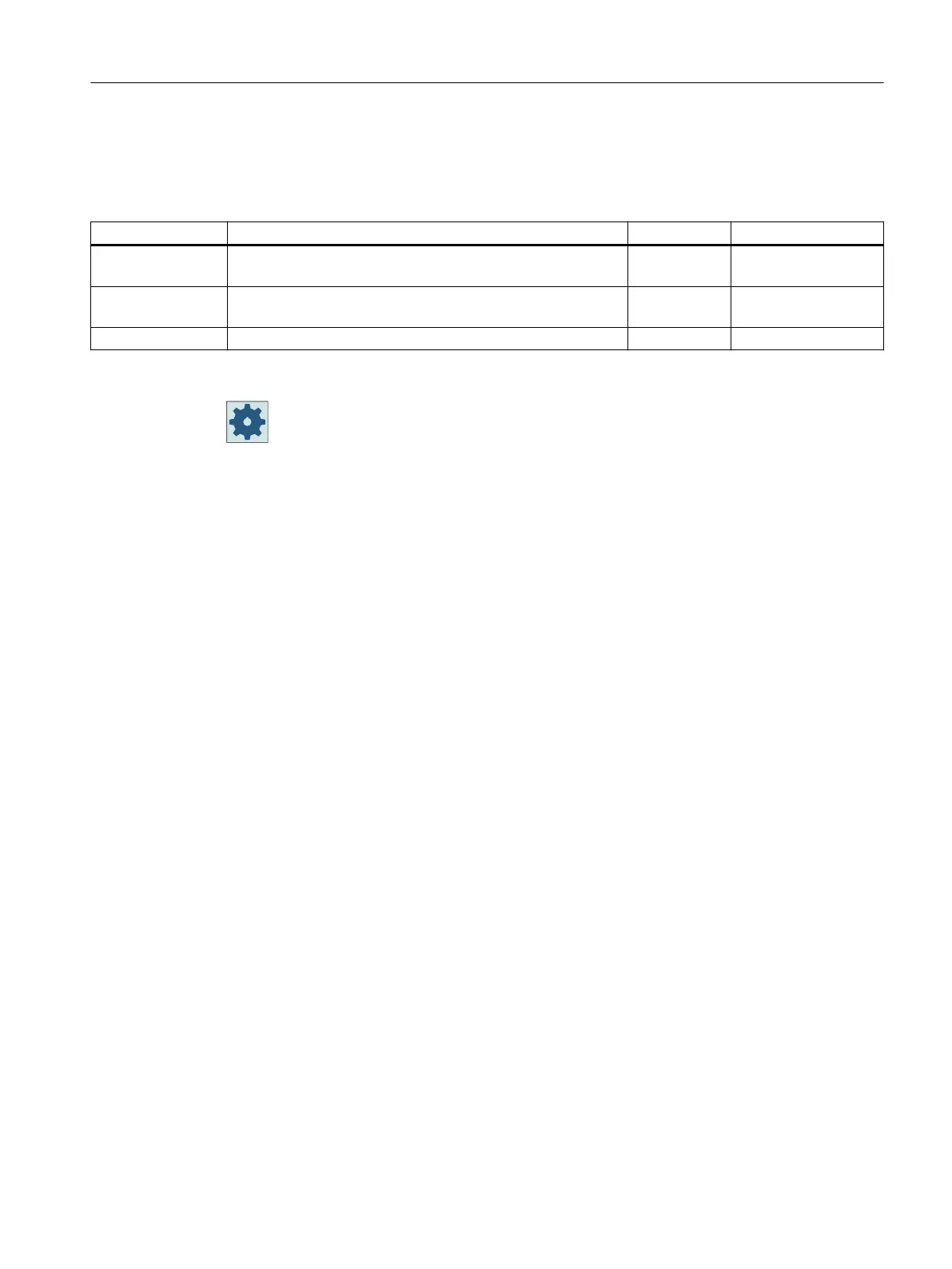

Parameter Description Value Can be set in SD

PL (only for G code) Machining plane Defined in MD

52005

SC (only for G

code)

Safety clearance 1 mm x

α0 Angle of rotation 0°

Machine manufacturer

Please refer to the machine manufacturer's specifications.

10.4.9 Open groove (CYCLE899)

Function

Use the "Open slot" function if you want to machine open slots.

For roughing, you can choose between the following machining strategies, depending on your

workpiece and machine properties.

● Vortex milling

● Plunge cutting

The following machining types are available to completely machine the slot:

● Roughing

● Rough-finishing

● Finishing

● Base finishing

● Edge finishing

● Chamfering

Vortex milling

Particularly where hardened materials are concerned, this process is used for roughing and

contour machining using coated VHM milling cutters.

Vortex milling is the preferred technique for HSC roughing, as it ensures that the tool is never

completely inserted. This means that the set overlap is precisely maintained.

Programming technology functions (cycles)

10.4 Milling

Turning

Operating Manual, 06/2019, A5E44903486B AB 541

Loading...

Loading...