If you program a thread run-out > 0, an additional thread block is generated at the end of the

thread.

Note

Commands DITS and DITE

In CYCLE99, the commands DITS and DITE are not programmed. The setting data SD 42010

$SC_THREAD_RAMP_DISP[0] and [1] are not changed.

The parameters thread run-in (LW2) and thread run-out (LR) used in the cycles have a purely

geometrical meaning. They do not influence the dynamic response of the thread blocks. The

parameters result internally in a concatenation of several thread blocks.

Procedure for thread chain

1. The part program or ShopTurn program to be processed has been cre‐

ated and you are in the editor.

2. Press the "Turning" softkey.

3. Press the "Thread" softkey.

The "Thread" input window opens.

4. Press the "Thread chain" softkey.

The "Thread Chain" input window opens.

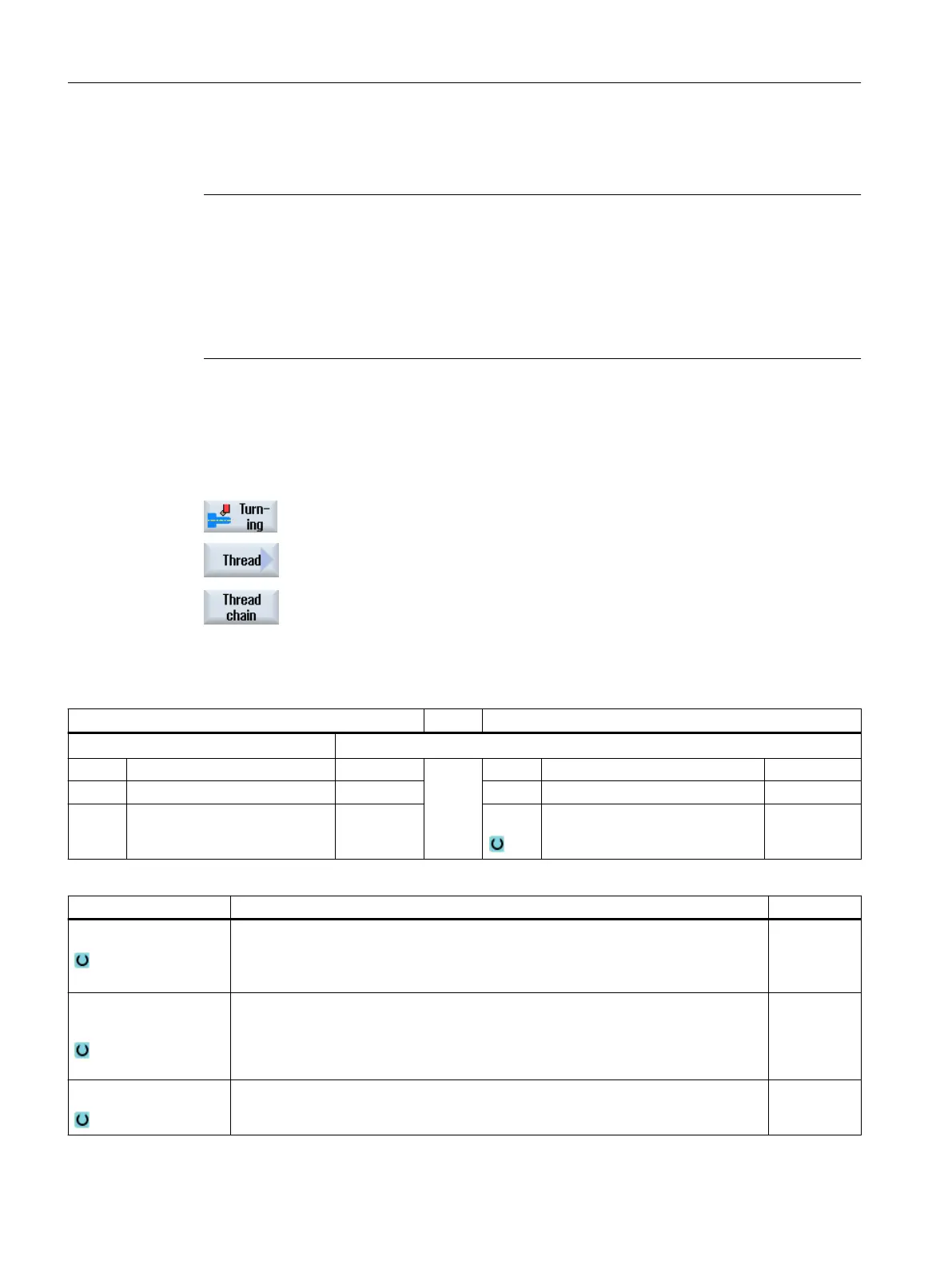

Parameters in the "Input complete" mode

G code program parameters ShopTurn program parameters

Input

● Complete

PL Machining plane T Tool name

SC Safety clearance mm D Cutting edge number

S / V Spindle speed or constant cutting

rate

rpm

m/min

Parameter Description Unit

Machining

● ∇ (roughing)

● ∇∇∇ (finishing)

● ∇ + ∇∇∇ (roughing and finishing)

Infeed (only for ∇ and ∇

+ ∇∇∇)

● Linear:

Constant cutting depth infeed

● Degressive:

Constant cutting cross-section infeed

Thread

● Internal thread

● External thread

Programming technology functions (cycles)

10.2 Rotate

Turning

436 Operating Manual, 06/2019, A5E44903486B AB

Loading...

Loading...