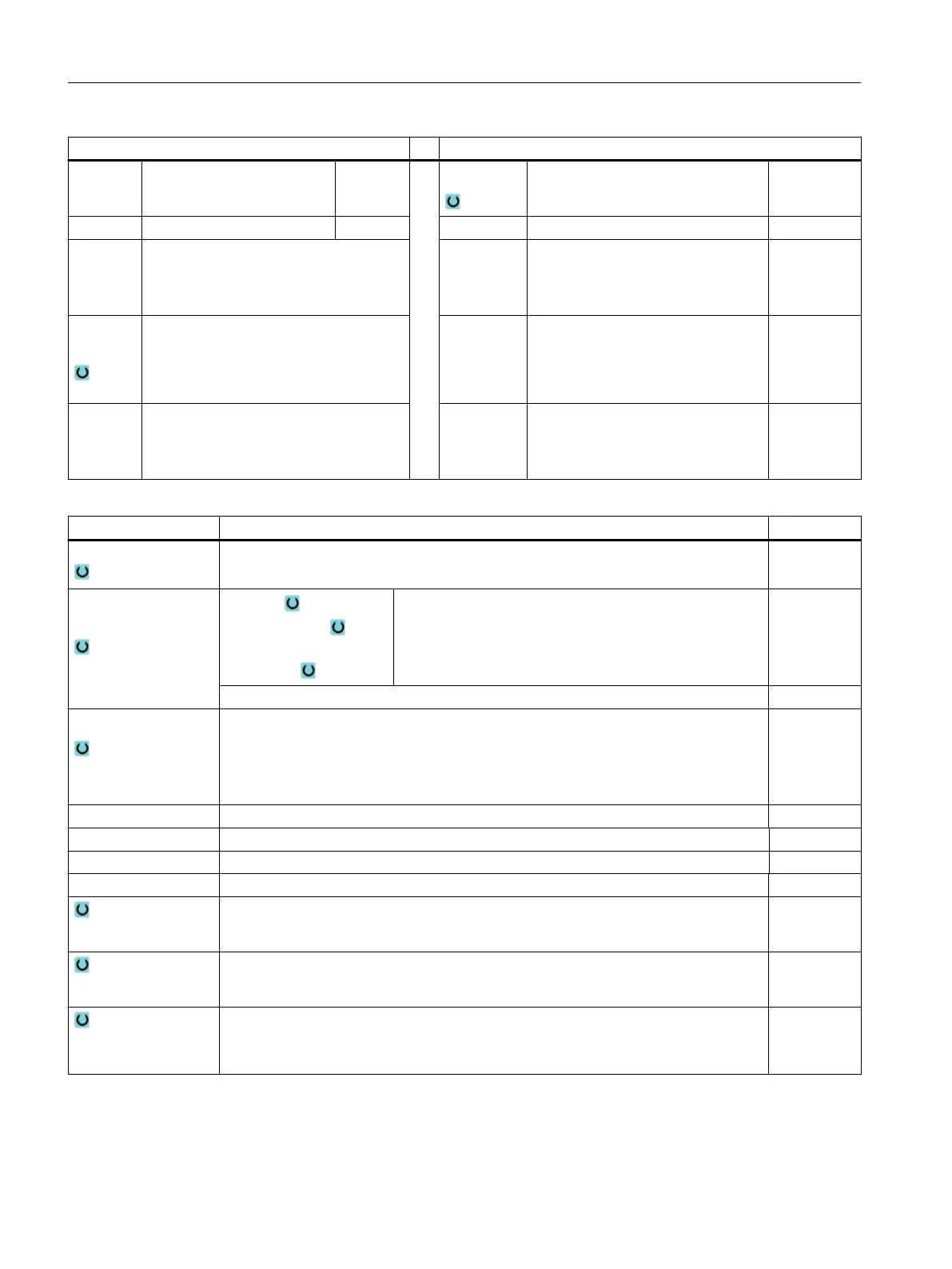

G code program parameters ShopTurn program parameters

SC Safety clearance mm S / V Spindle speed or constant cutting

rate

rpm

m/min

F Feedrate *

CON Name of the updated blank contour for

residual material machining (without the

attached character "_C" and double-digit

number)

Residual

material

With subsequent residual material re‐

moval

● Yes

● No

CONR Name to save the updated unmachined-

part contour for residual material remov‐

al - (only "Yes" for residual material re‐

moval)

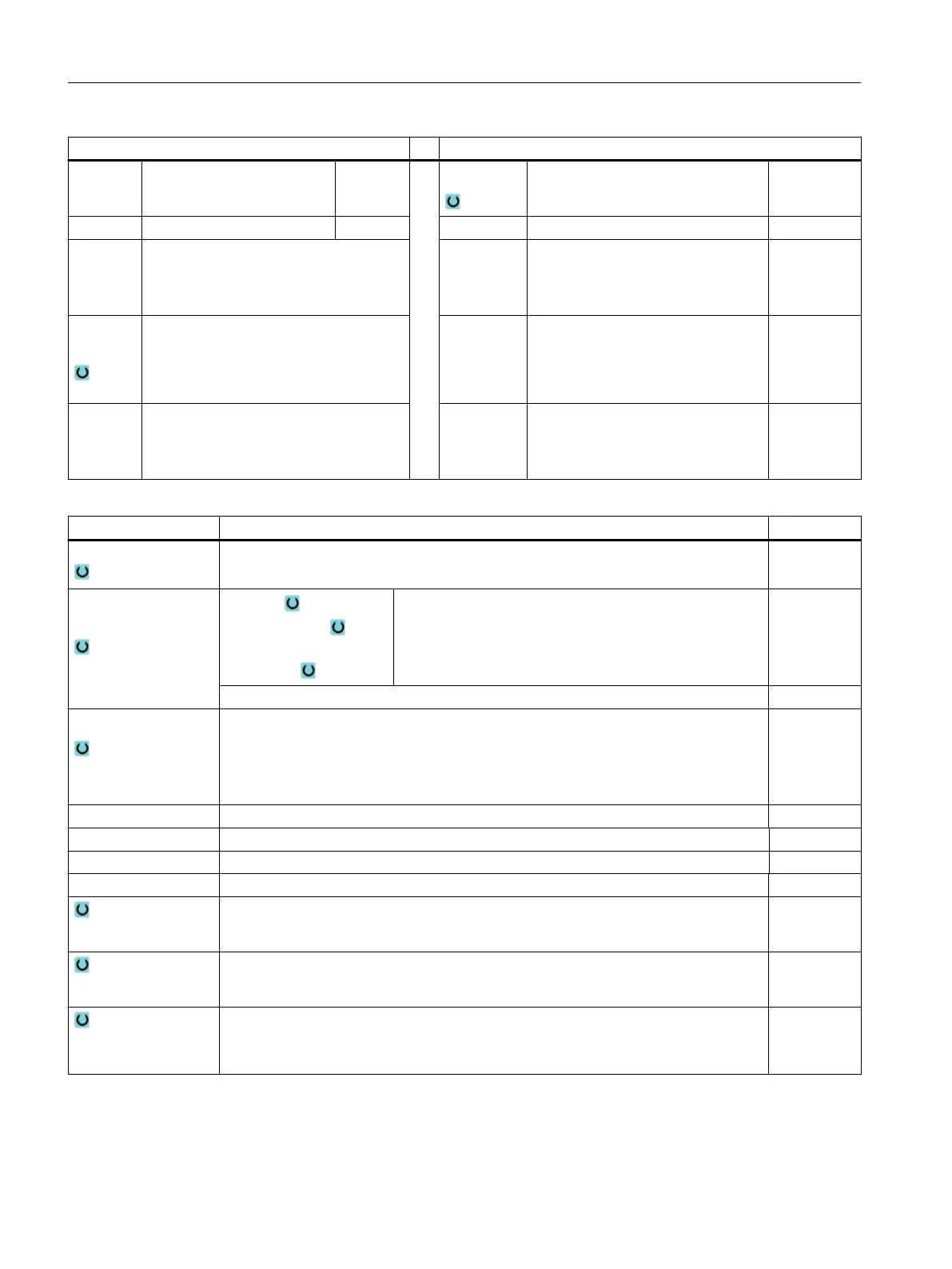

Parameter Description Unit

Machining

● ∇ (roughing)

● ∇∇∇ (finishing)

Machining

direction

● Face

● Longitudinal

● Parallel to the

contour

● From inside to outside

● From outside to inside

● From end face to rear side

● From rear side to end face

The machining direction depends on the stock removal direction and choice of tool.

Position

● front

● rear

● Internal

● external

D Maximum depth infeed - (only for ∇) mm

XDA First grooving limit tool (abs) – (only for face machining direction) mm

XDB Second grooving limit tool (abs) – (only for face machining direction) mm

DX Maximum depth infeed - (only for parallel to the contour, as an alternative to D) mm

Do not round contour at end of cut.

Always round contour at end of cut.

Uniform cut segmentation

Round cut segmentation at the edge

only for align cut segmentation at the edge:

Constant cutting depth

alternating cutting depth

Programming technology functions (cycles)

10.3 Contour turning

Turning

466 Operating Manual, 06/2019, A5E44903486B AB

Loading...

Loading...