For more detailed information, please refer to section "Stock removal".

Procedure

1. The part program or ShopTurn program to be processed has been cre‐

ated and you are in the editor.

2. Press the "Contour turning" softkey.

3. Press the "Plunge turning" softkey.

The "Plunge turning" input window opens.

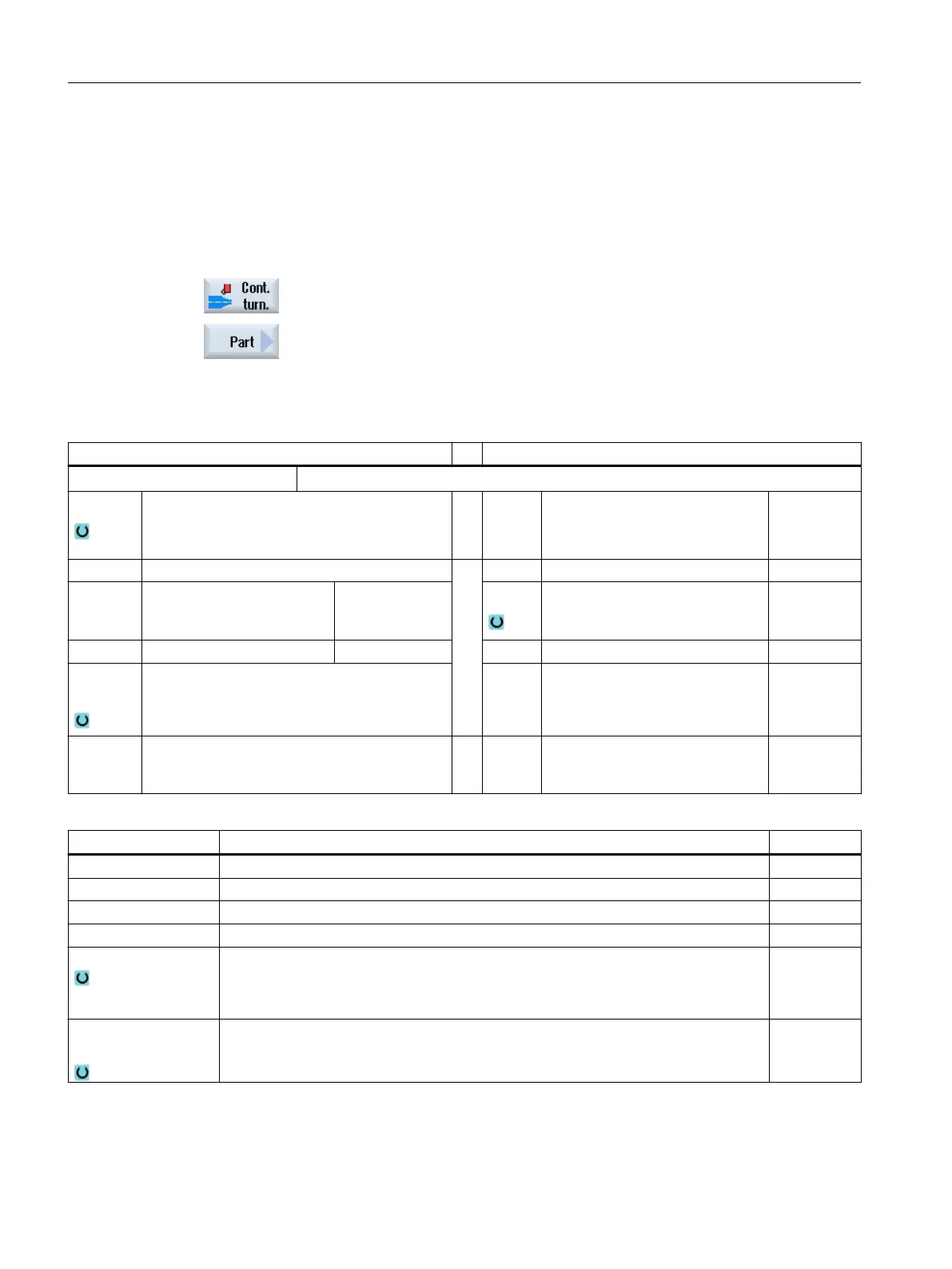

Parameters in the "Input complete" mode

G code program parameters ShopTurn program parameters

Input

● Complete

PRG

● Name of the program to be generated

● Auto

Automatic generation of program names

T Tool name

PL Machining plane D Cutting edge number

RP Retraction plane – (only for

machining direction, longitu‐

dinal, inner)

mm S / V Spindle speed or constant cutting

rate

rpm

m/min

SC Safety clearance mm

Residual

material

With subsequent residual material removal

● Yes

● No

CONR Name to save the updated unmachined-part

contour for residual material removal - (only

"Yes" for residual material removal)

Parameter Description Unit

FX (only ShopTurn) Feedrate in X direction mm/rev

FZ (only ShopTurn) Feedrate in Z direction mm/rev

FX (only G Code) Feedrate in X direction *

FZ (only for G code) Feedrate in Z direction *

Machining

● ∇ (roughing)

● ∇∇∇ (finishing)

● ∇+∇∇∇ (complete machining)

Machining

direction

● Face

● Longitudinal

Programming technology functions (cycles)

10.3 Contour turning

Turning

478 Operating Manual, 06/2019, A5E44903486B AB

Loading...

Loading...