UM0306 General purpose timer (TIMx)

245/519

13.4.12 Encoder interface mode

To select Encoder Interface mode write SMS=‘001’ in the TIMx_SMCR register if the

counter is counting on TI2 edges only, SMS=’010’ if it is counting on TI1 edges only and

SMS=’011’ if it is counting on both TI1 and TI2 edges.

Select the TI1 and TI2 polarity by programming the CC1P and CC2P bits in the TIMx_CCER

register. When needed, you can program the input filter as well.

The two inputs TI1 and TI2 are used to interface to an incremental encoder. Refer to

Table 3 9. The counter is clocked by each valid transition on TI1FP1 or TI2FP2 (TI1 and TI2

after input filter and polarity selection, TI1FP1=TI1 if not filtered and not inverted,

TI2FP2=TI2 if not filtered and not inverted) assuming that it is enabled (CEN bit in

TIMx_CR1 register written to ‘1’). The sequence of transitions of the two inputs is evaluated

and generates count pulses as well as the direction signal. Depending on the sequence the

counter counts up or down, the DIR bit in the TIMx_CR1 register is modified by hardware

accordingly. The DIR bit is calculated at each transition on any input (TI1 or TI2), whatever

the counter is counting on TI1 only, TI2 only or both TI1 and TI2.

Encoder interface mode acts simply as an external clock with direction selection. This

means that the counter just counts continuously between 0 and the auto-reload value in the

TIMx_ARR register (0 to ARR or ARR down to 0 depending on the direction). So you must

configure TIMx_ARR before starting. In the same way, the capture, compare, prescaler,

trigger output features continue to work as normal.

In this mode, the counter is modified automatically following the speed and the direction of

the incremental encoder and its content, therefore, always represents the encoder’s

position. The count direction correspond to the rotation direction of the connected sensor.

The table summarizes the possible combinations, assuming TI1 and TI2 don’t switch at the

same time.

An external incremental encoder can be connected directly to the MCU without external

interface logic. However, comparators are normally be used to convert the encoder’s

differential outputs to digital signals. This greatly increases noise immunity. The third

encoder output which indicate the mechanical zero position, may be connected to an

external interrupt input and trigger a counter reset.

The Figure 106 gives an example of counter operation, showing count signal generation and

direction control. It also shows how input jitter is compensated where both edges are

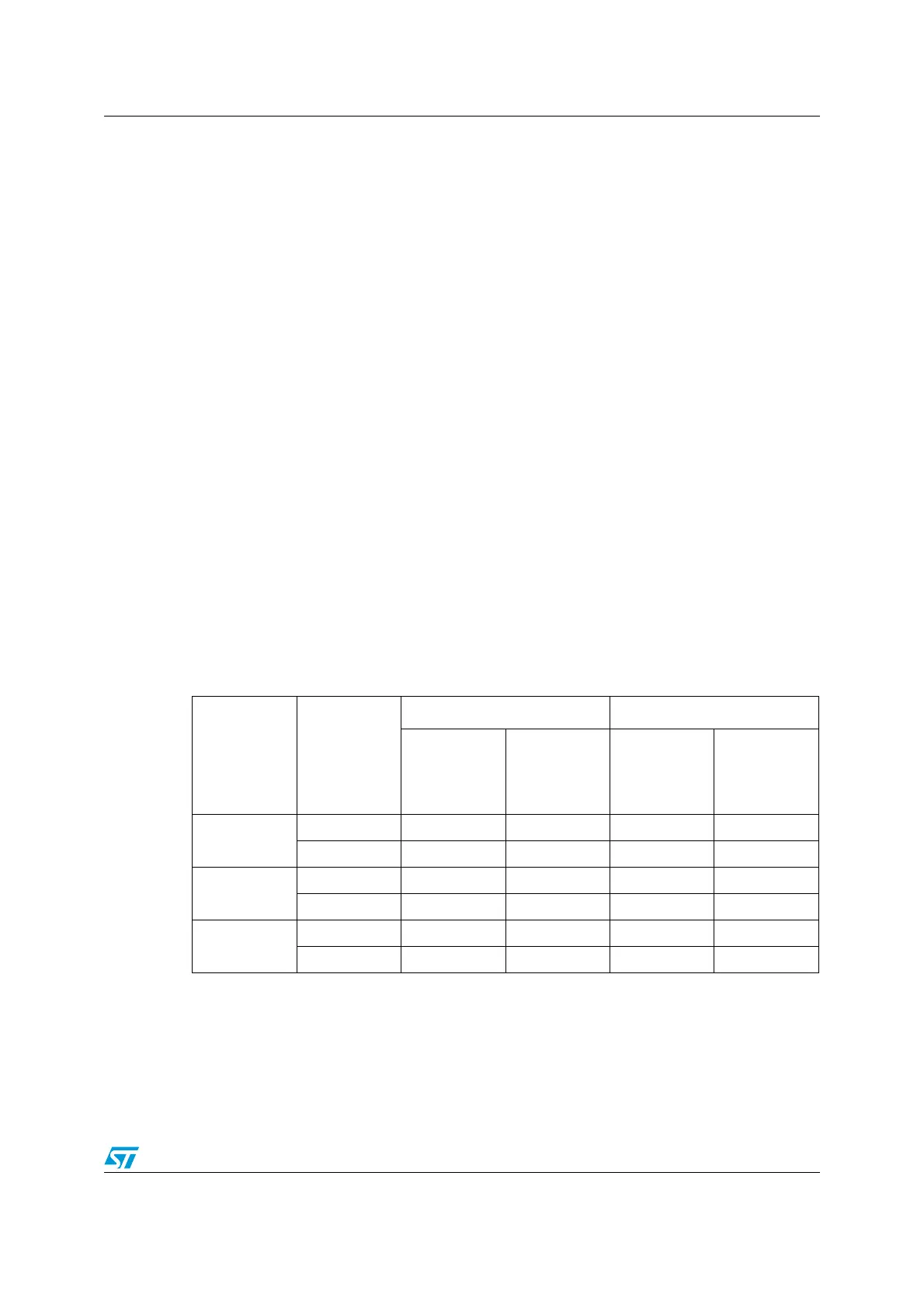

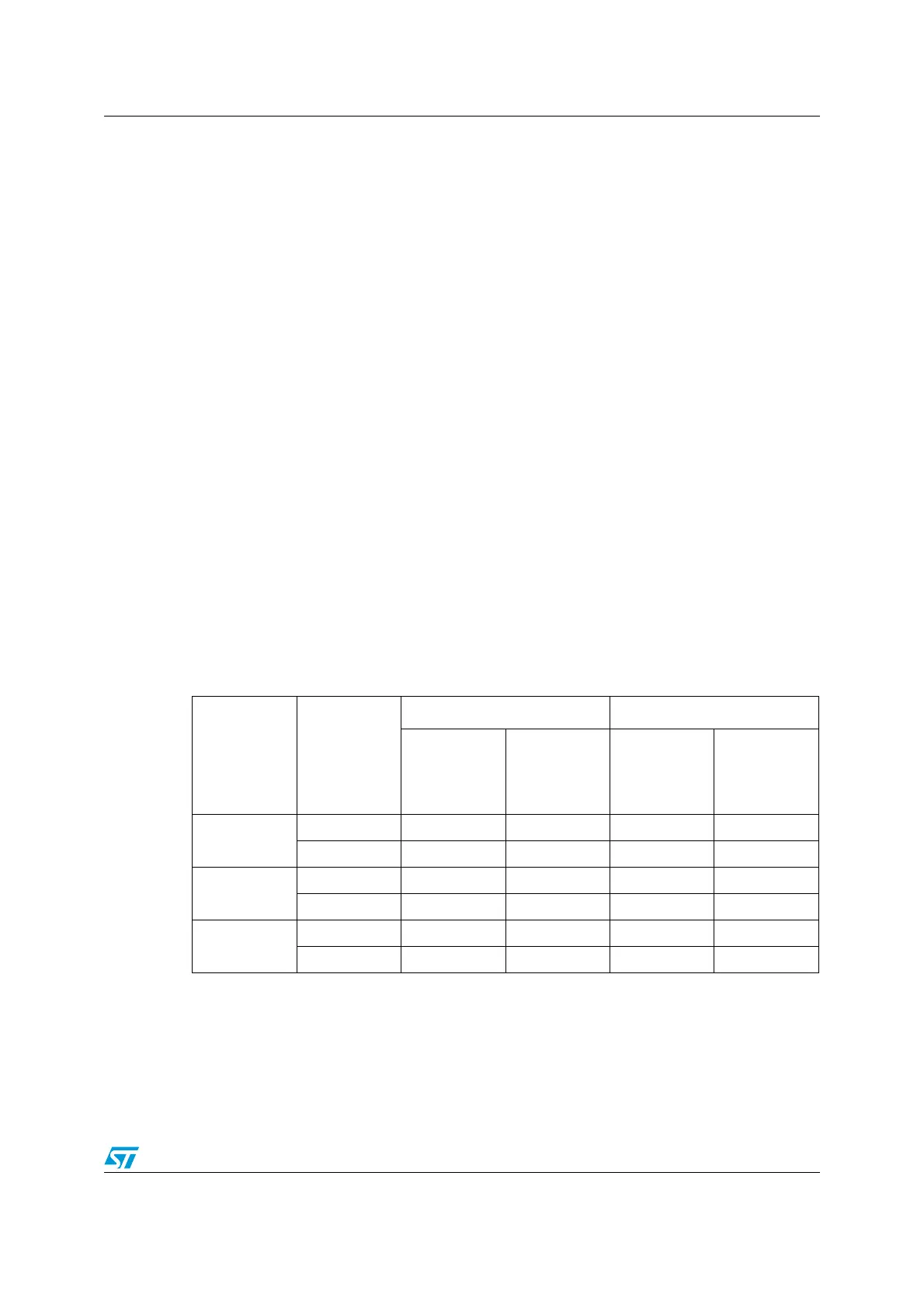

Table 39. Counting direction versus encoder signals

Active Edge

Level on

opposite

signal (TI1FP1

for TI2,

TI2FP2 for

TI1)

TI1FP1 signal TI2FP2 signal

Rising Falling Rising Falling

Counting on

TI1 only

High Down Up No Count No Count

Low Up Down No Count No Count

Counting on

TI2 only

High No Count No Count Up Down

Low No Count No Count Down Up

Counting on

TI1 and TI2

High Down Up Up Down

Low Up Down Down Up

Loading...

Loading...