13.16

SEL-400 Series Relays Instruction Manual Date Code 20171006

SELOGIC Control Equation Programming

SEL

OGIC Control Equation Elements

NOTE: Times for protection timers

must not exceed 2,000,000 cycles for

proper operation.

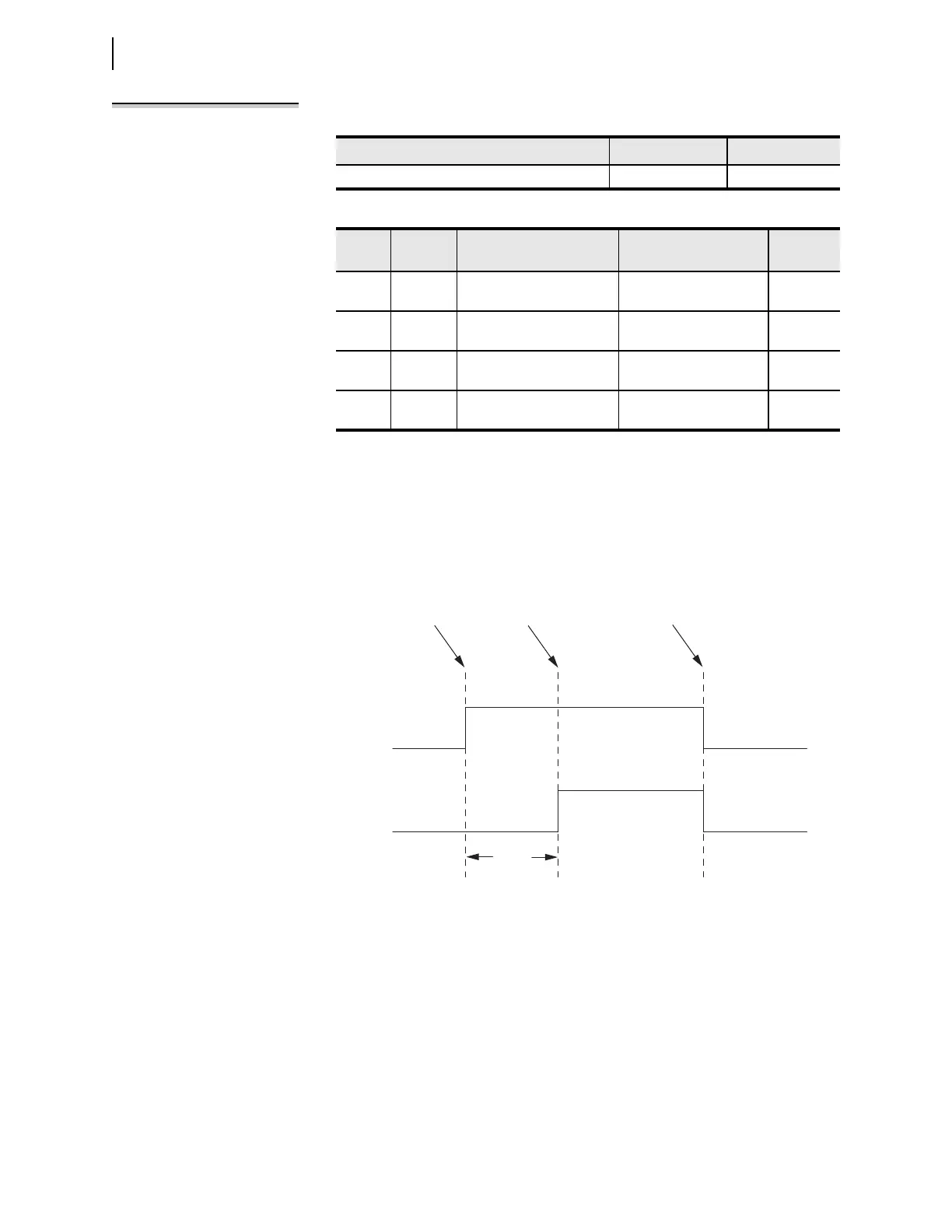

A conditioning timer output turns on and becomes logical 1, after the input turns

on and the Pickup Time expires. An example timing diagram for a conditioning

timer, PCT01, with a Pickup Time setting greater than zero and a Dropout Time

setting of zero is shown in Figure 13.3. In the example timing diagram, the Input,

PCT01IN, turns on and the timer Output, PCT01Q, turns on after the Pickup

Time, PCT01PU, expires. Because the Dropout Time setting is zero, the Output

turns off when the Input turns off.

If the Pickup Time is not satisfied, the timer Output never turns on, as illustrated

in Figure 13.4. If the input reasserts again, one or more processing intervals later,

the conditioning timer pickup timer begins timing again from zero.

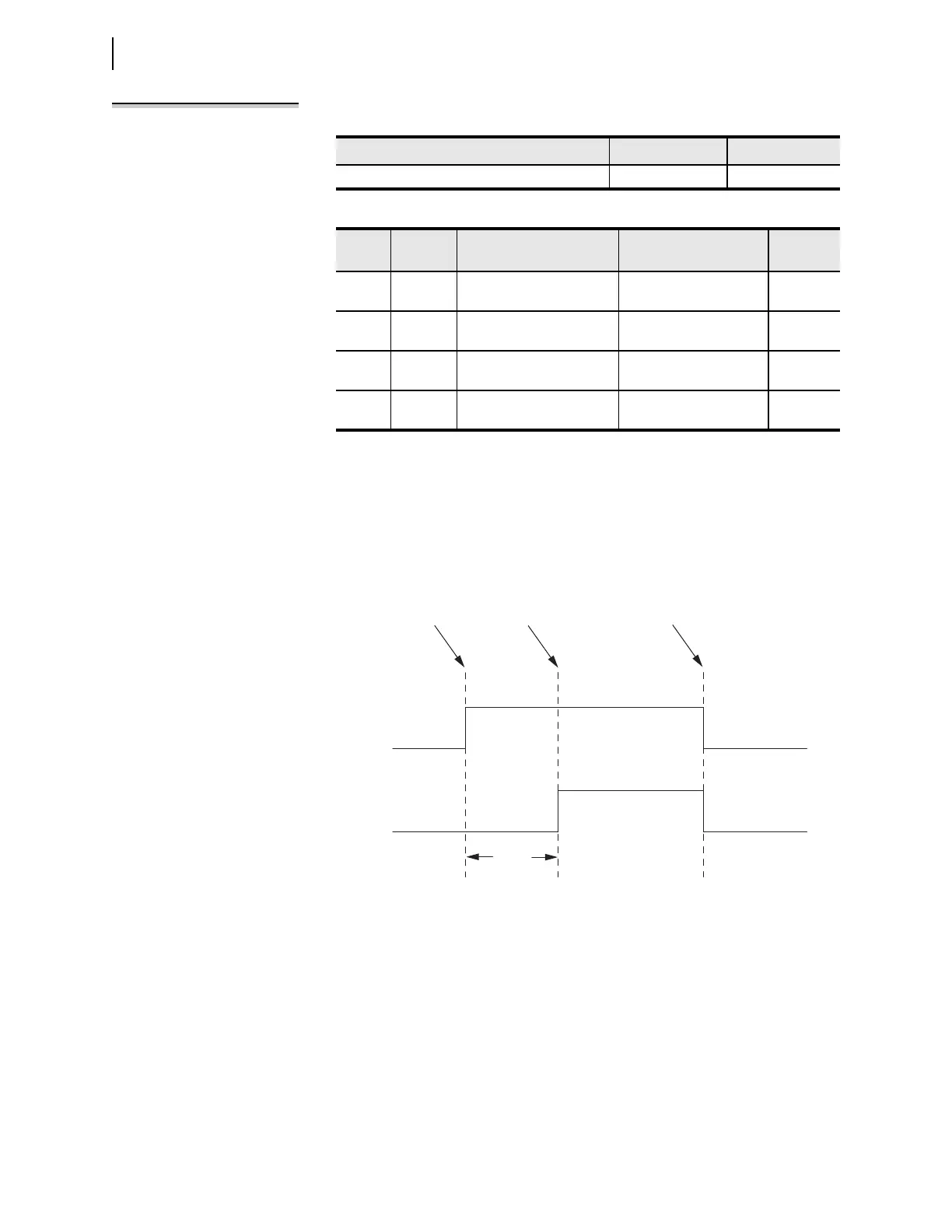

Table 13.9 Conditioning Timer Quantities

Type Typical Quantity Name Range

Protection freeform conditioning timers 32 PCT01–PCT32

Table 13.10 Conditioning Timer Parameters

Type Item Description Setting

Name

Examples

Input Input Value that the relay times Boolean SELOGIC control

equation setting

PCT01IN

Input Pickup

Time

Time that the input must be

on before the output turns on

Time value in cycles PCT01PU

Input Dropout

Time

Time that the output stays on

after the input turns off

Time value in cycles PCT01DO

Output Output Timer output Value for Boolean

SEL

OGIC control equations

PCT01Q

Figure 13.3 Conditioning Timer With Pickup and No Dropout Timing Diagram

PCT01IN

PCT01Q

Input Changes

from 0 to 1

Input Changes

from 1 to 0

Pickup

Time

PCT01PU

Pickup Time

Expires

Loading...

Loading...