MAINTENANCE OPERATIONS

ENGINE

Cold Engine Operations

1. (3VZ–E ENGINE)

REPLACE TIMING BELT

(a) Remove the timing belt.

(See pages EG–32)

(b) Install the timing belt.

(See pages EG–41)

2. INSPECT DRIVE BELTS

(a) Visually check the belt for excessive wear, frayed

cords etc.

HINT:

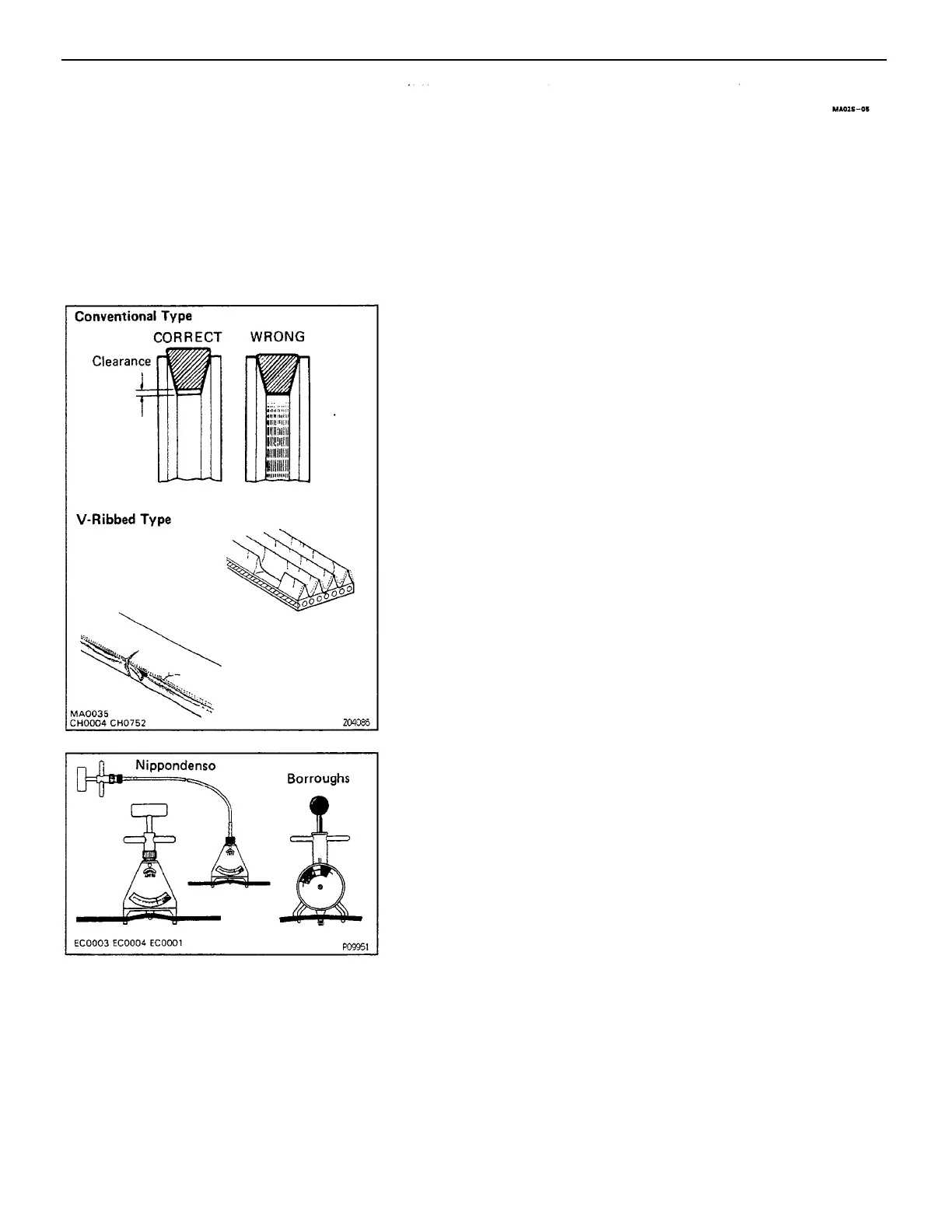

Conventional type:

Check that the belt does not touch the bottom of the

pulley groove.

If necessary, replace the drive belt.

V–Ribbed type:

Cracks on the ribbed side of the belt are considered

acceptable.

If the belt has chunks missing from the ribs, it should

be replaced.

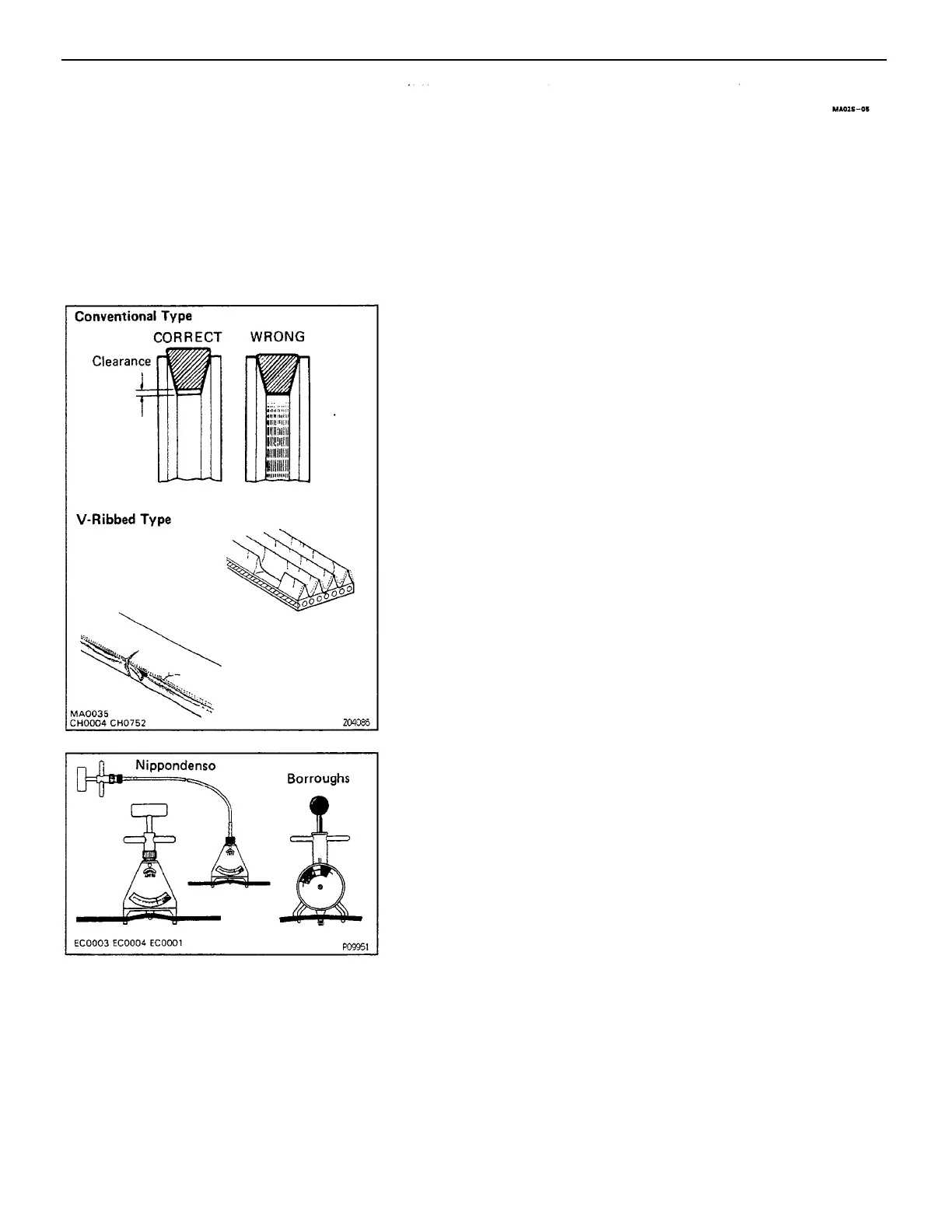

(b) Using a belt tension gauge, check the drive belt ten–

sion.

Belt tension gauge:

Nippondenso BTG – 20 (95506–00020) or

Borroughs No. BT–33–73F

Drive belt tension:

22R–E Used belt 80

± 20 lbf

New belt 125

± 25 lbf

3VZ – E

Generator Used belt 100

± 20 lbf

New belt 160

± 20 lbf

PS Used belt 80

± 20 lbf

New belt 125

± 25 lbf

A/C Used belt 80 20 lbf

New belt 125

± 25 lbf

If necessary, adjust the drive belt tension.

–MAINTENANCE MAINTENANCE OPERATIONS

MA–6

Loading...

Loading...