GENERATOR DRIVE BELT INSPECTION

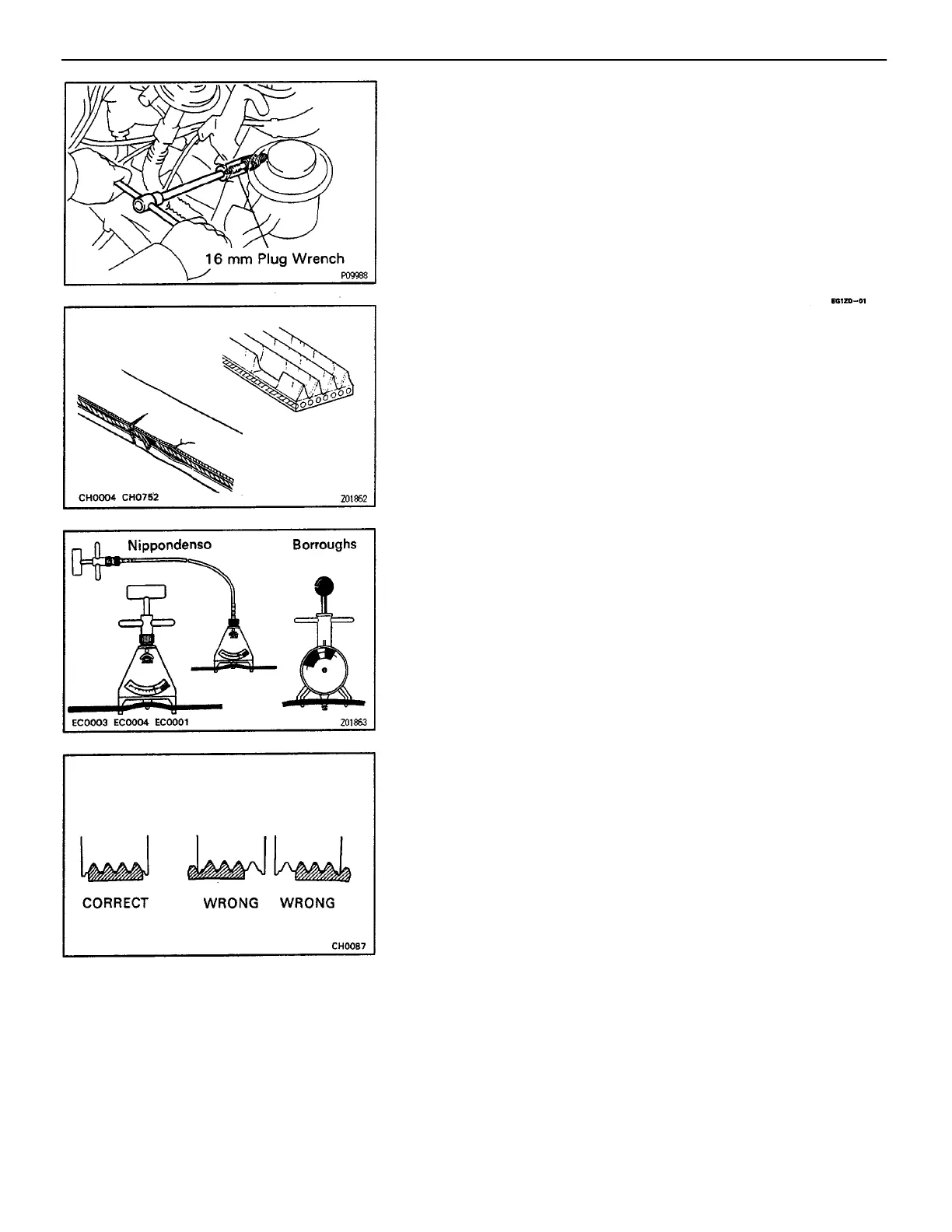

INSPECT DRIVE BELTS

(a) Visually check the belt for excessive wear, frayed

cords etc.

If necessary, replace the drive belt.

HINT: Cranks on the rib side of a belt are considered

acceptable. If the belt has chunks missing from the

ribs, it should be replaced.

(b) Using a belt tension gauge, measure the belt tension.

Belt tension gauge:

BTG–20 (95506–00020) for nippondenso

No. BT–33–73F for borroughs

Drive belt tension:

New belt

160 ±20 lbf

Used belt

100 ±20 lbf

If necessary, adjust the belt tension.

HINT:

• ”New belt” refers to a belt which has been used

less than 5 minutes on a running engine.

• ”Used belt” refers to a belt which has been used

on a running engine for 5 minutes or more.

• After installing the belt, check that it fits properly

in the ribbed grooves.

• Check by hand to confirm that the belt has not

slipped out of the groove on the bottom of the

pulley.

• After installing a new belt, run the engine for

about 5 minutes and recheck the belt tension.

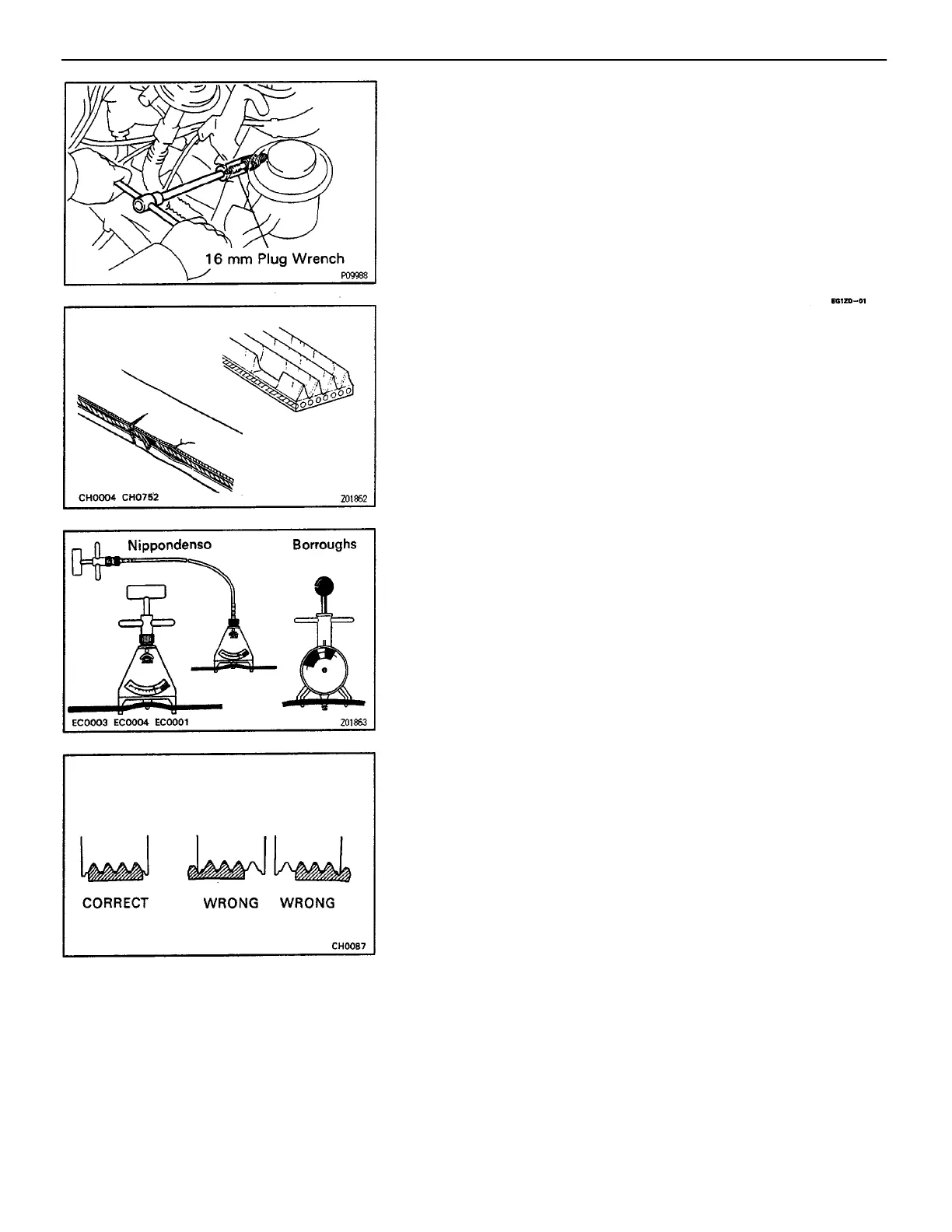

6. INSTALL SPARK PLUGS

Using a 16 mm plug wrench, install the six spark

plugs.

Torque: 18 N–m (18o kgf–cm, 13 ft–lbf)

7. RECONNECT HIGH–TENSION CORDS TO SPARK

PLUGS

–ENGINE ENGINE MECHANICAL

EG2–17

Loading...

Loading...