COMPRESSION CHECK

HINT: If there is lack of power, excessive oil con–

sumptiom or poor fuel economy, measure the com–

pression pressure.

1. WARM UP AND STOP ENGINE

Allow the engine to warm up to normal operating

temperature.

2. REMOVE AIR CLEANER HOSE

3. DISCONNECT COLD START INJECTOR

CONNECTOR

4. DISCONNECT IGNITER CONNECTOR

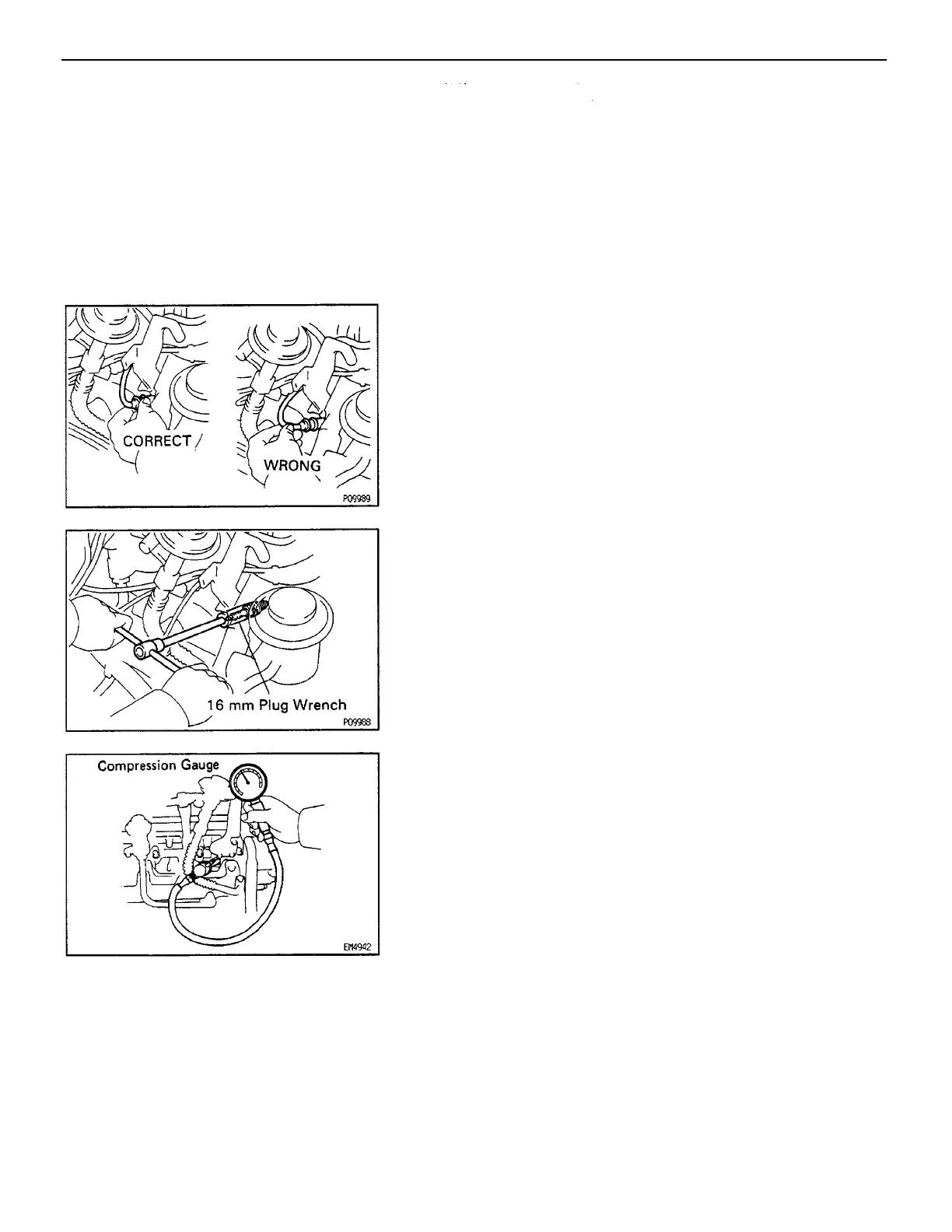

5. DISCONNECT HIGH–TENSION CORDS FROM

SPARK PLUGS

Disconnect the high – tension cords at the rubber

boot. Do not pull on the cords.

NOTICE: Pulling on or bending the cords may damage the

conductor inside.

7. CHECK CYLINDER COMPRESSION PRESSURE

(a) Insert a compression gauge into the spark plug hole.

(b) Fully open the throttle.

(c) While cranking the engine, measure the compression

pressure.

HINT: Always use a fully charged battery to obtain

engine speed of 250 rpm or more.

(d) Repeat steps

(a) through

(c) for each cylinder.

NOTICE: This measurement must be done in as short a

time as possible.

Compression pressure:

1,177 kPa (12.0 kg f/cm

2

, 171 psi) .

Minimum pressure:

981 kPa (10.0 kg f/cm

2

, 142 psi)

Difference between each cylinder:

98 kPa (1.0 kg f/cm

2

, 14 psi) or less

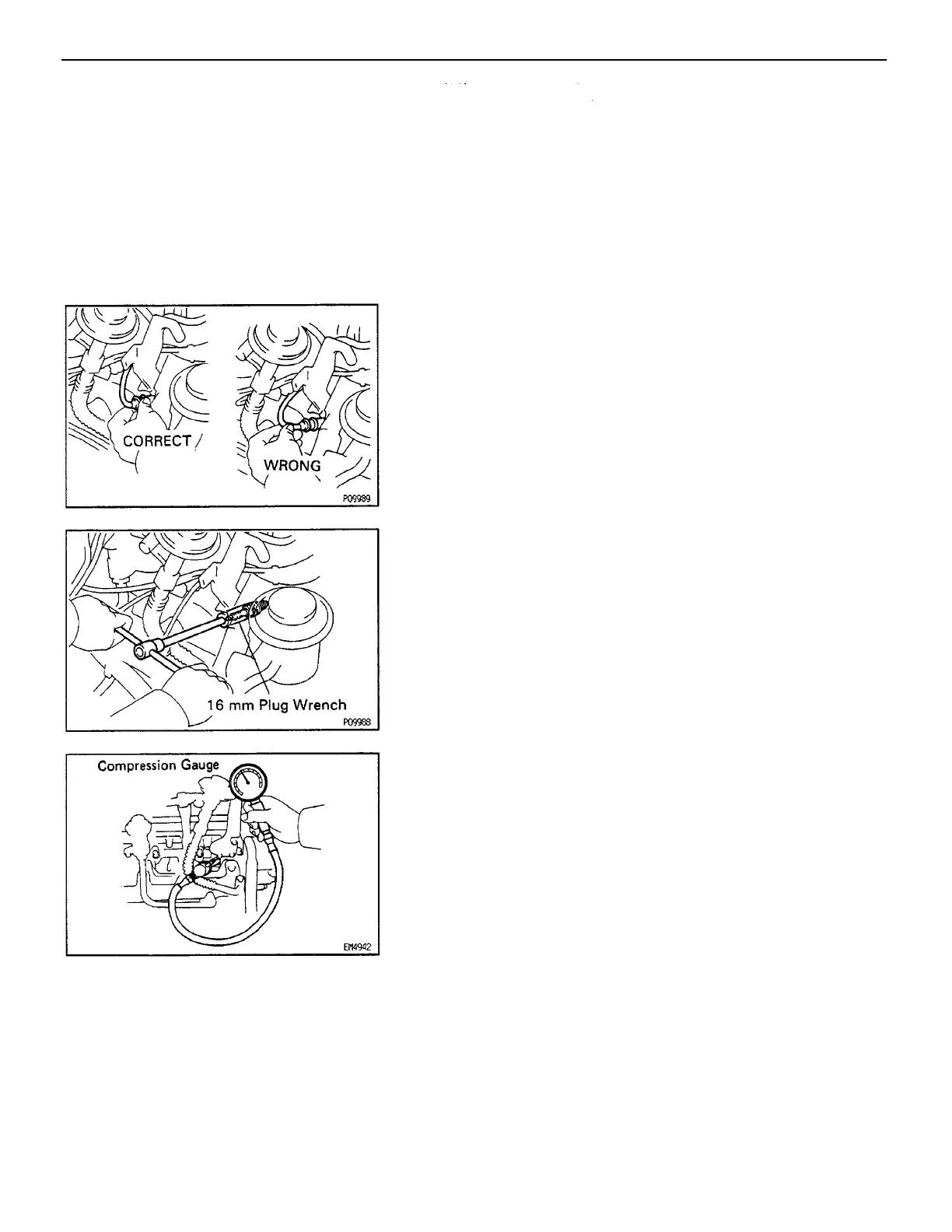

6. REMOVE SPARK PLUGS

Using a 16 mm plug wrench, remove the six spark

plugs.

–ENGINE ENGINE MECHANICAL

EG2–30

Loading...

Loading...