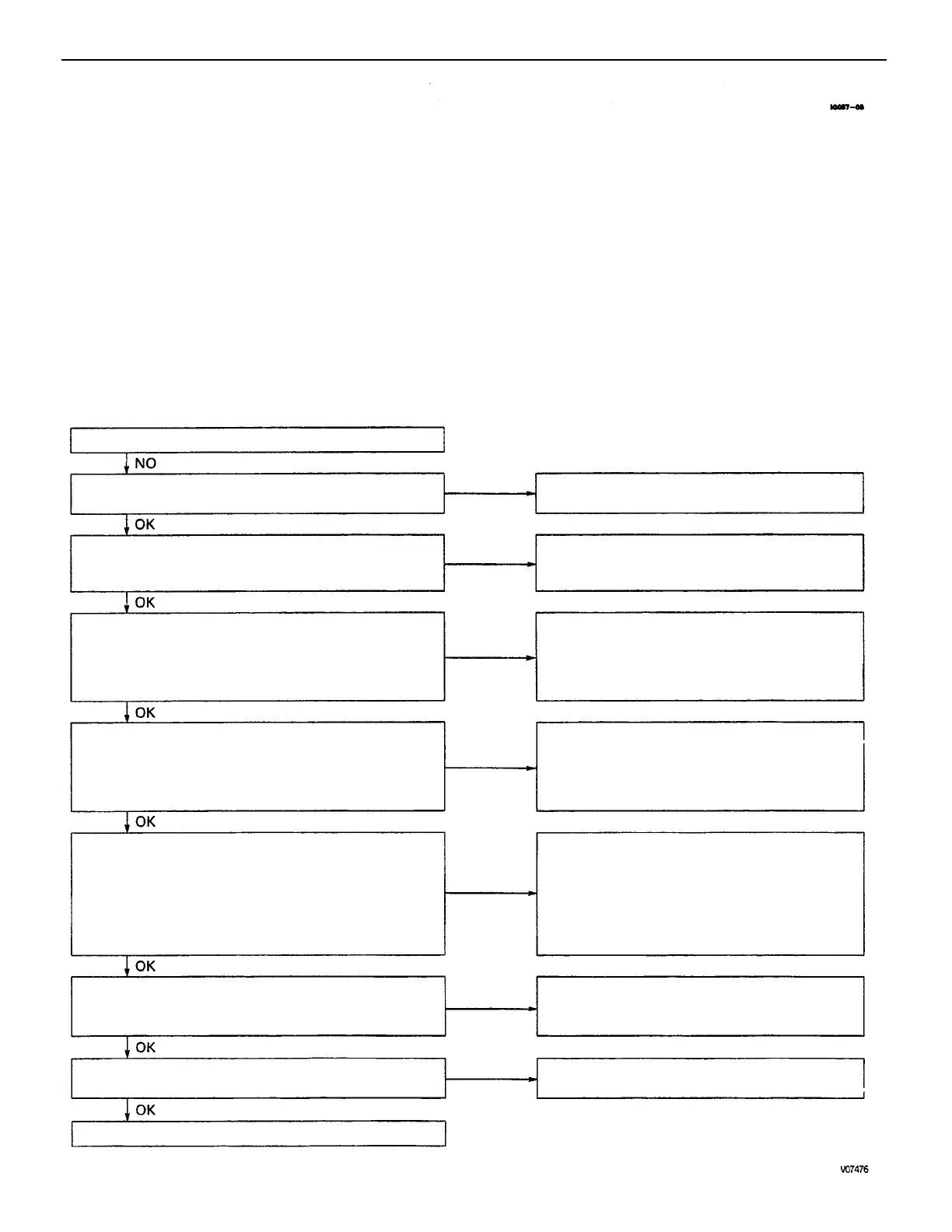

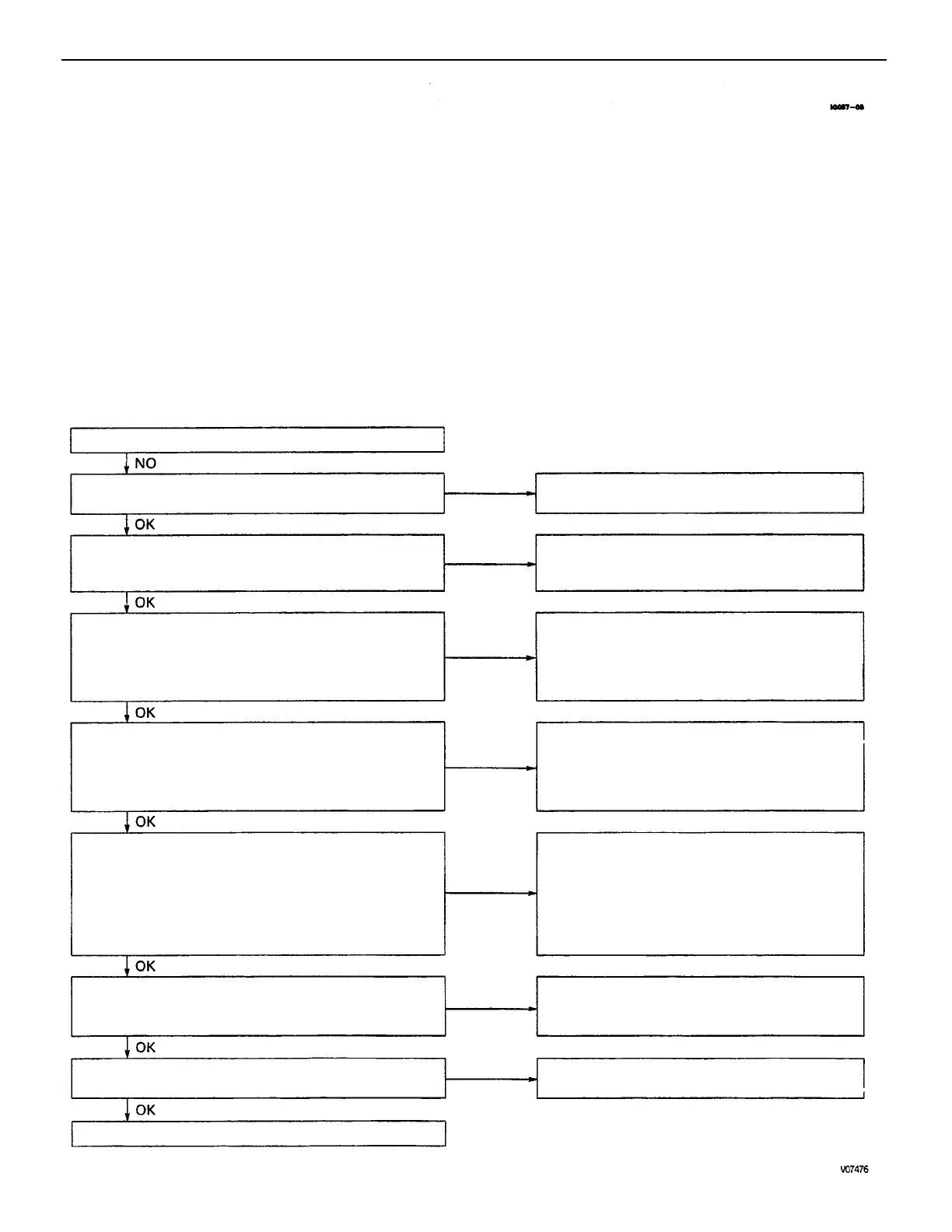

ON–VEHICLE INSPECTION

SPARK TEST

CHECK THAT SPARK OCCURS

(a) Disconnect high–tension cord from the distributor.

(b) Hold the end approx. 12.5 mm (0.50 in.) from engine

ground of vehicle.

(c) See if spark occurs while engine is being cranked.

HINT: 1’o prevent gasoline from being injected from

injectors during this test, crank the engine for no more

than 1 – 2 seconds at a time.

If the spark does not occur, perform the test as fol–

lows:

CHECK RESISTANCE OF SIGNAL GENERATOR

(PICKUP COIL)

(See page IG–23)

Resistance: (Cold) (Hot)

G 1 and G(–) 125–200 160–235

G2 and G(–) 125–200 160 – 235

NE and G(–) 155 – 250 190 – 290

CHECK POWER SUPPLY TO IGNITION COIL AND

IG NITER .

1. Turn ignition switch to ON. –

2. Check that there is battery voltage at ignition coil

positive (+) terminal.

CHECK RESISTANCE OF IGNITION COIL

(See page IG–22)

Resistance: (Cold) (Hot)

Primary 0.36 – 0.55 0.45 – 0.65

Secondary 9.0 –15.4 11.4 – 18.1 k

CHECK RESISTANCE OF HIGH–TENSION CORD

(See page IG–19)

Maximum resistance: 25 k per cord

CHECK AIR GAP OF DISTRIBUTOR

(See page IG–23)

Air gap: 0.2 – 0.4 mm (0.008 – 0.016 in.)

Check wiring between ignition switch to

ignition coil and igniter.

CHECK CONNECTION OF IGNITION COIL, IG-

NITER AND DISTRIBUTOR CONNECTOR

Check wiring between ECM, distributor and

igniter, and then try another ECM.

CHECK IGT SIGNAL FROM ECM

(See page EG–195)

Replace the distributor housing assembly.

Replace the distributor housing assembly.

Replace the ignition coil.

TRY ANOTHER IGNITER

Replace the cord(s).

Connect securely.

SPARK TEST

BAD

BAD

BAD

BAD

BAD

BAD

BAD

–IGNITION SYSTEM (3VZ–E)

IG–18

Loading...

Loading...