(d) Check the surface of the valve stem tip for wear.

If the valve stem tip is worn, regrind it with grinder or

replace the valve if necessary.

NOTICE: Do not grind off more than minimum overall

length.

Minimum overall length:

Intake 113.0 mm (4.449 in.)

Exhaust 111.9 mm (4.406 in.)

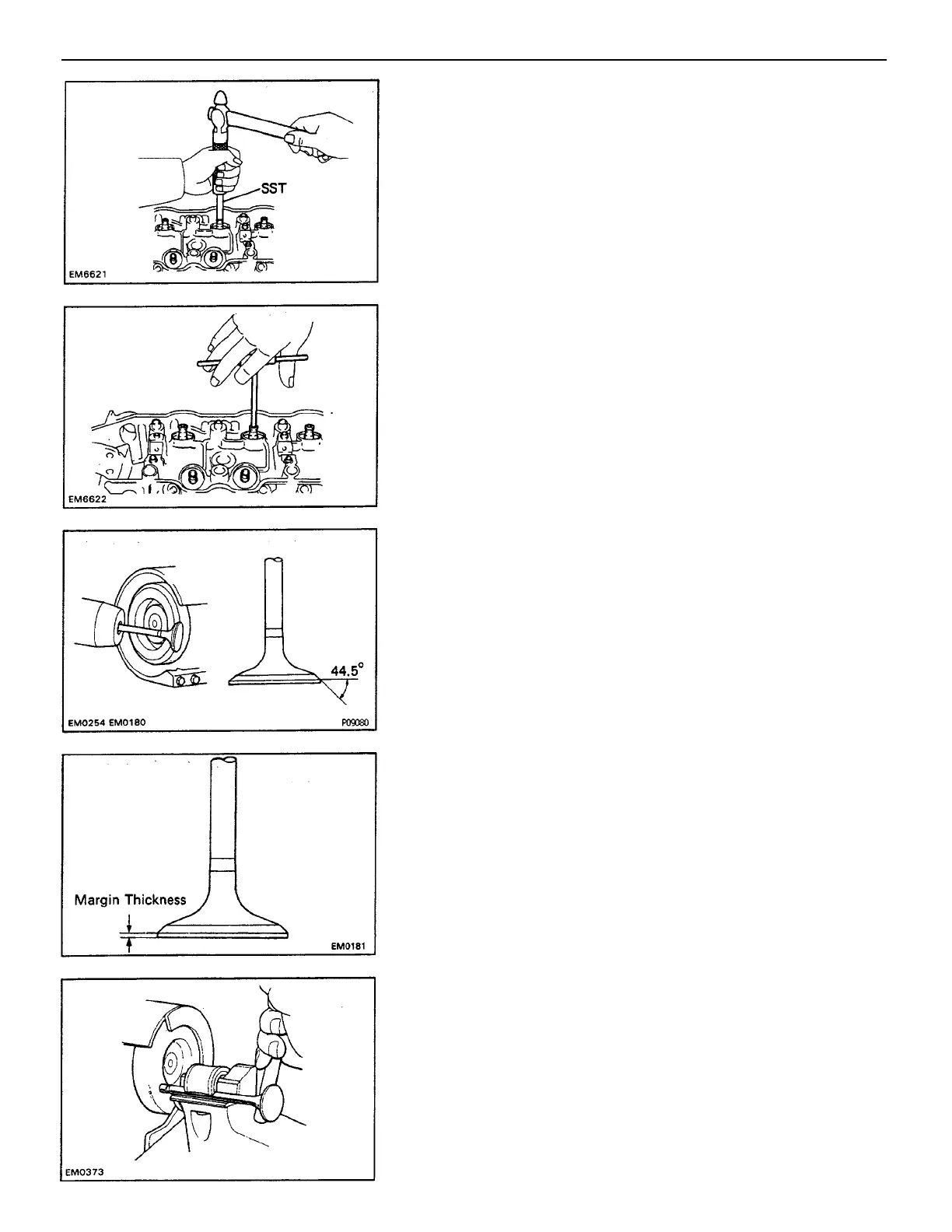

(f) Gradually heat the cylinder head to approx. 90C

(194 F).

(g) Using SST a and hammer, drive in a new valve guide

bushing unit the snap ring makes contact with the

cylinder head.

SST 09201–6001 1

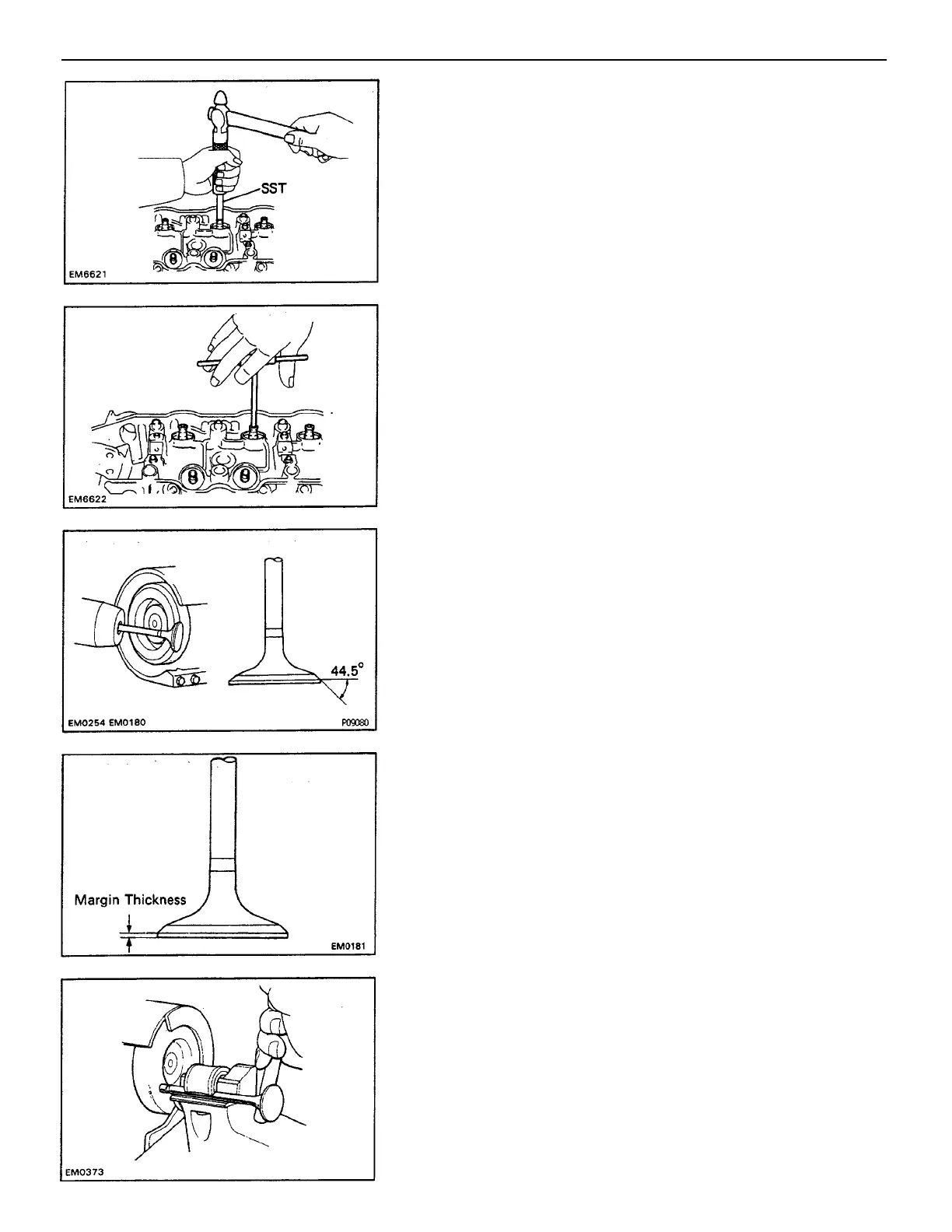

11. INSPECT AND GRIND VALVES

(a) Grind the valve only enough to remove pits and

carbon.

(b) Check that valve is ground to the correct valve face

angle.

Valve face angle: 44.5

(c) Check the valve head margin thickness.

Standard margin thickness: 1.0 mm (0.039 in.)

Minimum margin thickness: 0.6 mm (0.024 in.)

If the valve head margin thickness is less than mini–

mum, replace the valve.

(h) Using a sharp 8 mm (0.31 mm) reamer, ream the valve

guide bushing to obtain standard specified clearance

(See page EG1–23) between the valve guide bushing

and new valve.

–ENGINE ENGINE MECHANICAL

EG1–25

Loading...

Loading...