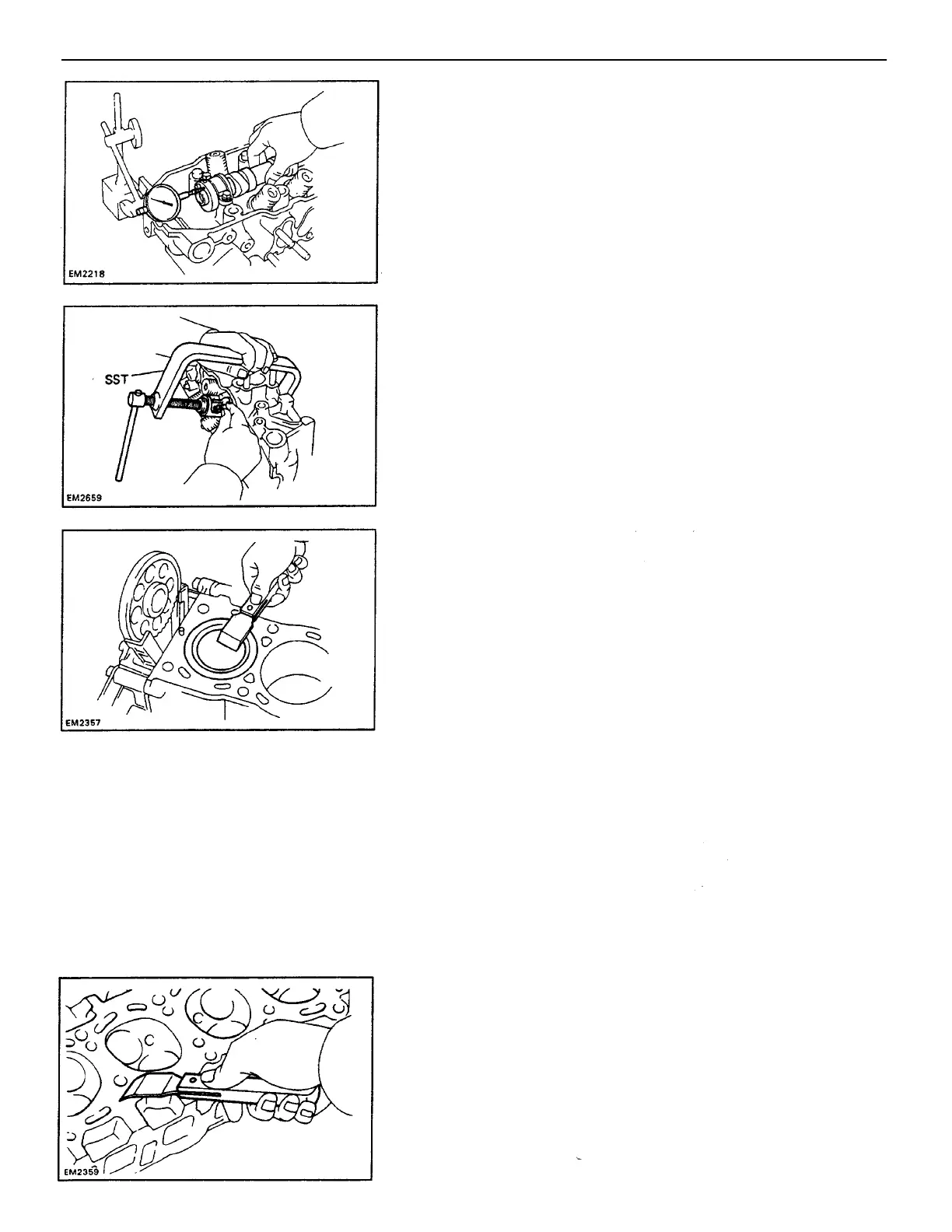

9. REMOVE VALVES

(a) Using SST, compress the valve retainer until the two

keepers can be removed.

SST 09202–43013

(b) Remove the valve keepers, retainer, spring and valve.

(c) Pry out the oil seal.

(d) Using a small screwdriver or magnet, remove the

valve spring seat.

HINT: Keep the valves arranged so they can be ins–

talled in the same order as removed.

INSPECTION, CLEANING AND REPAIR OF

CYLINDER HEAD COMPONENTS

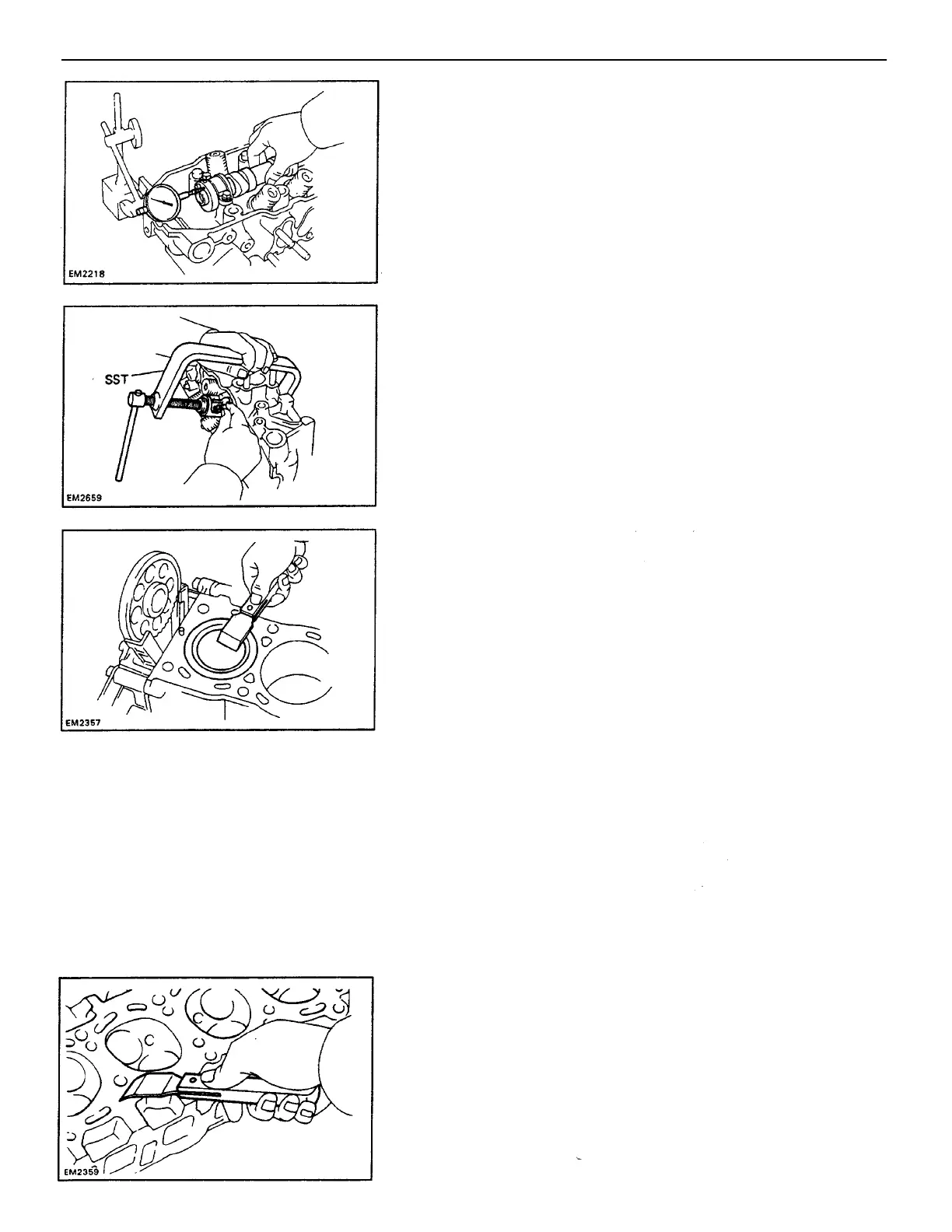

1. CLEAN TOP OF PISTONS AND TOP OF CYLINDER

BLOCK

(a) Turn the crankshaft and bring each piston to top dead

center. Using a gasket scraper, remove all the carbon

from the piston tops.

(b) Using a gasket scraper, remove all gasket material

from the top of the block. Blow carbon and oil from

the bolt holes.

CAUTION: Protect your eyes when using high pressure

sir.

7. MEASURE CAMSHAFT THRUST CLEARANCE

Using a dial gauge, measure the camshaft thrust clearance.

Standard clearance: 0.08 – 0.18 mm

(0.0031–0.0071 in.)

Maximum clearance: 0.25 mm (0.0098 in.)

If clearance is greater than maximum, replace the

head.

8. REMOVE CAM BEARING CAPS AND SHAFT

2. REMOVE GASKET MATERIAL

Using a gasket scraper, remove all gasket material

from the head and manifold surfaces.

NOTICE: Be careful not to scratch the surfaces.

–ENGINE ENGINE MECHANICAL

EG1–21

Loading...

Loading...