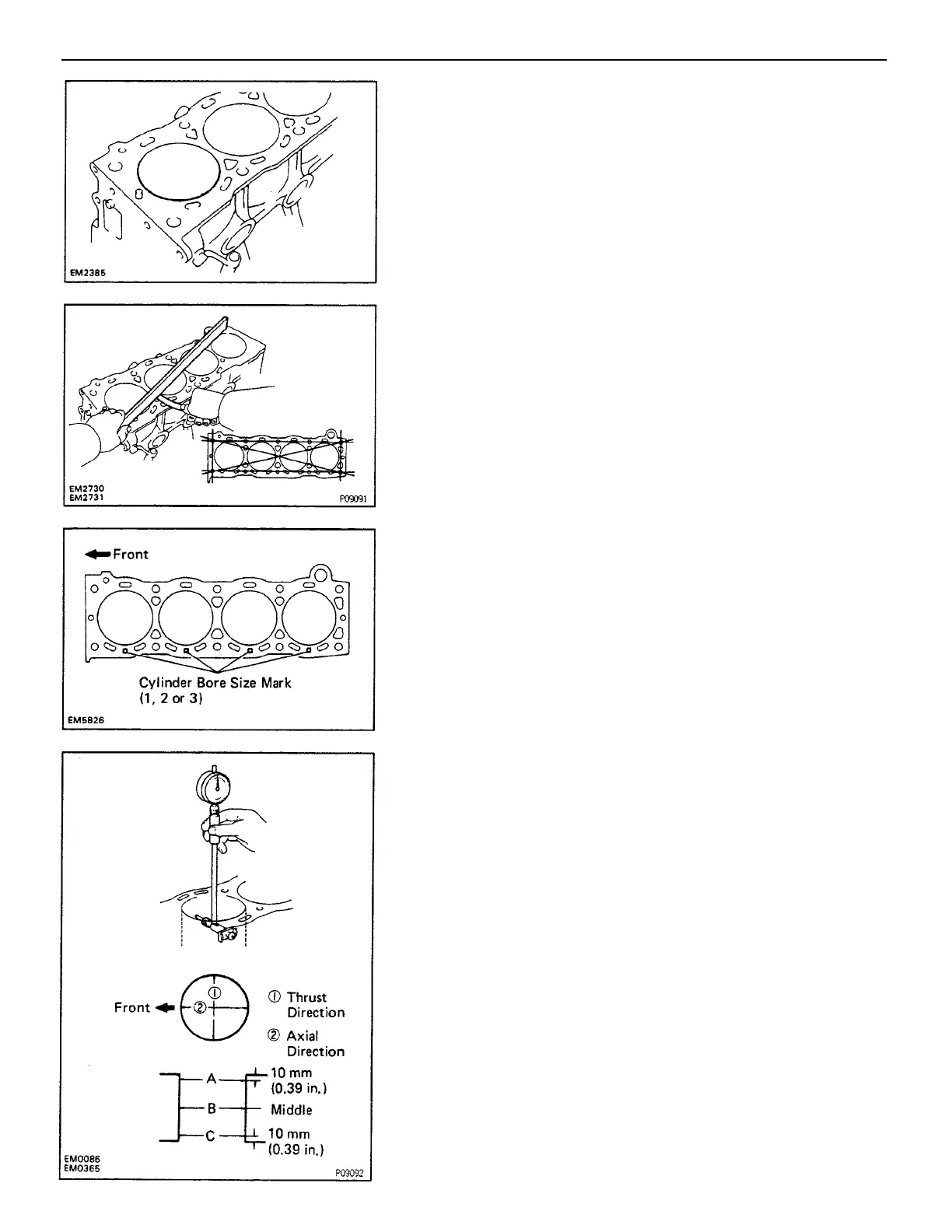

Using a cylinder gauge, measure the cylinder bore

diameter at positions A, B and C in the thrust and axial

directions.

Standard diameter:

STD Mark ’1’

92.00 – 92.01 mm

(3.6220 – 3.6224 in.)

Mark ’2’

92.01 – 92.02 mm

(3.6224 – 3.6228 in.)

Mark ’3’

92.02 – 92.03 mm

(3.6228 – 3.6232 in.)

O/S 0.50

92.50 – 92.53 m m

(3.6417 – 3.6429 in.)

1.00

93.00 – 93.03 mm

(3.6614 – 3:6626 in.)

5. MEASURE CYLINDER BORE

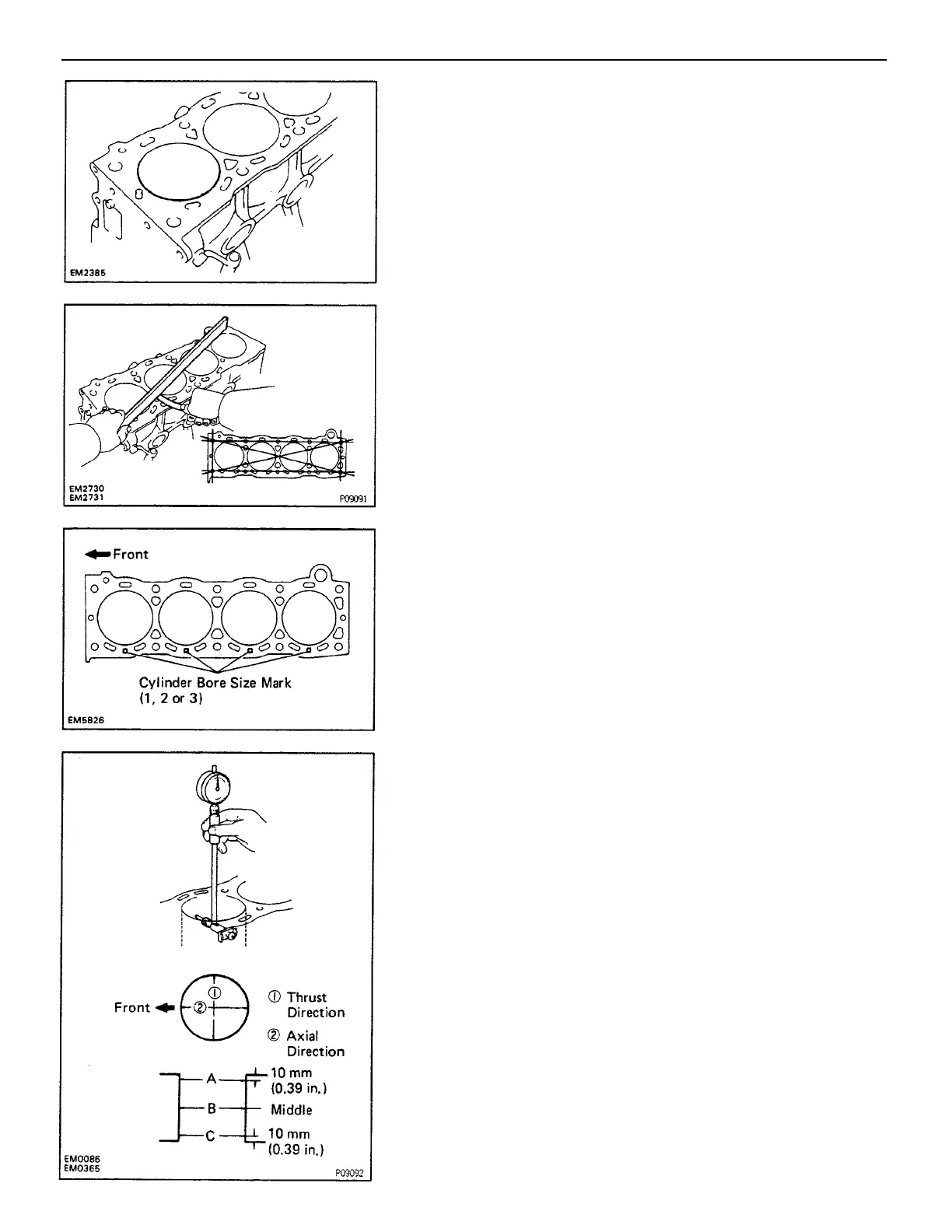

HINT: There are three sizes of the standard cylinder

bore diameter, marked ”1’, ”2”, and ”3”, accordingly.

The mark is stamped on the cylinder block.

3. INSPECT CYLINDERS

Visually inspect cylinders for vertical scratches.

If deep scratches are present, rebore all four cylinders.

(See page EG1–66)

4. INSPECT CYLINDER BLOCK WARPAGE

Warpage limit: 0.5 mm (0.0020 in.)

If warpage is greater than specified value, replace the

cylinder block.

–ENGINE ENGINE MECHANICAL

EG1–56

Loading...

Loading...