9. INSPECT VALVE SPRINGS

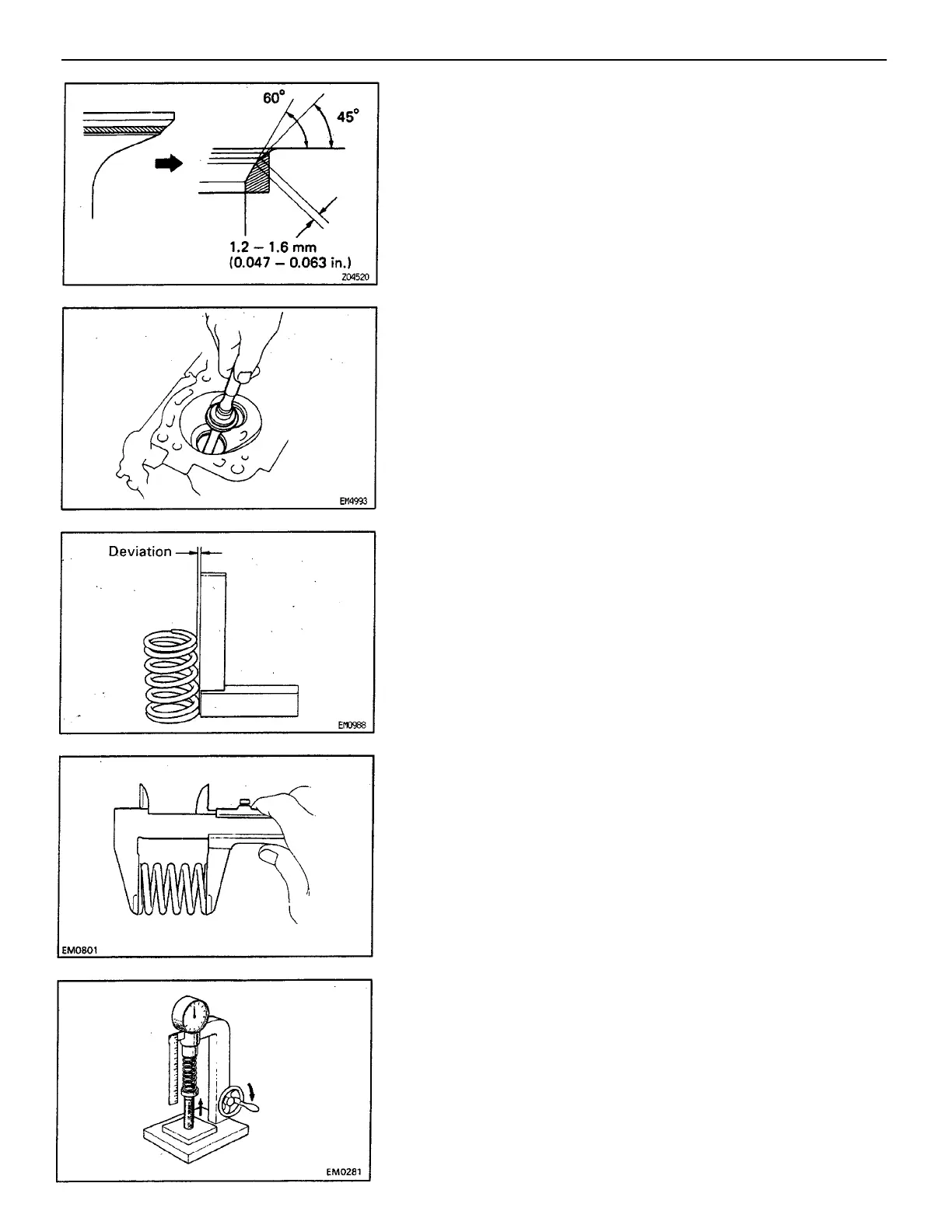

(a) Using a steel square, measure the deviation of the

valve spring.

Maximum deviation:

1.23 mm (0.0484 in.)

If the deviation is greater than maximum, replace the

valve spring.

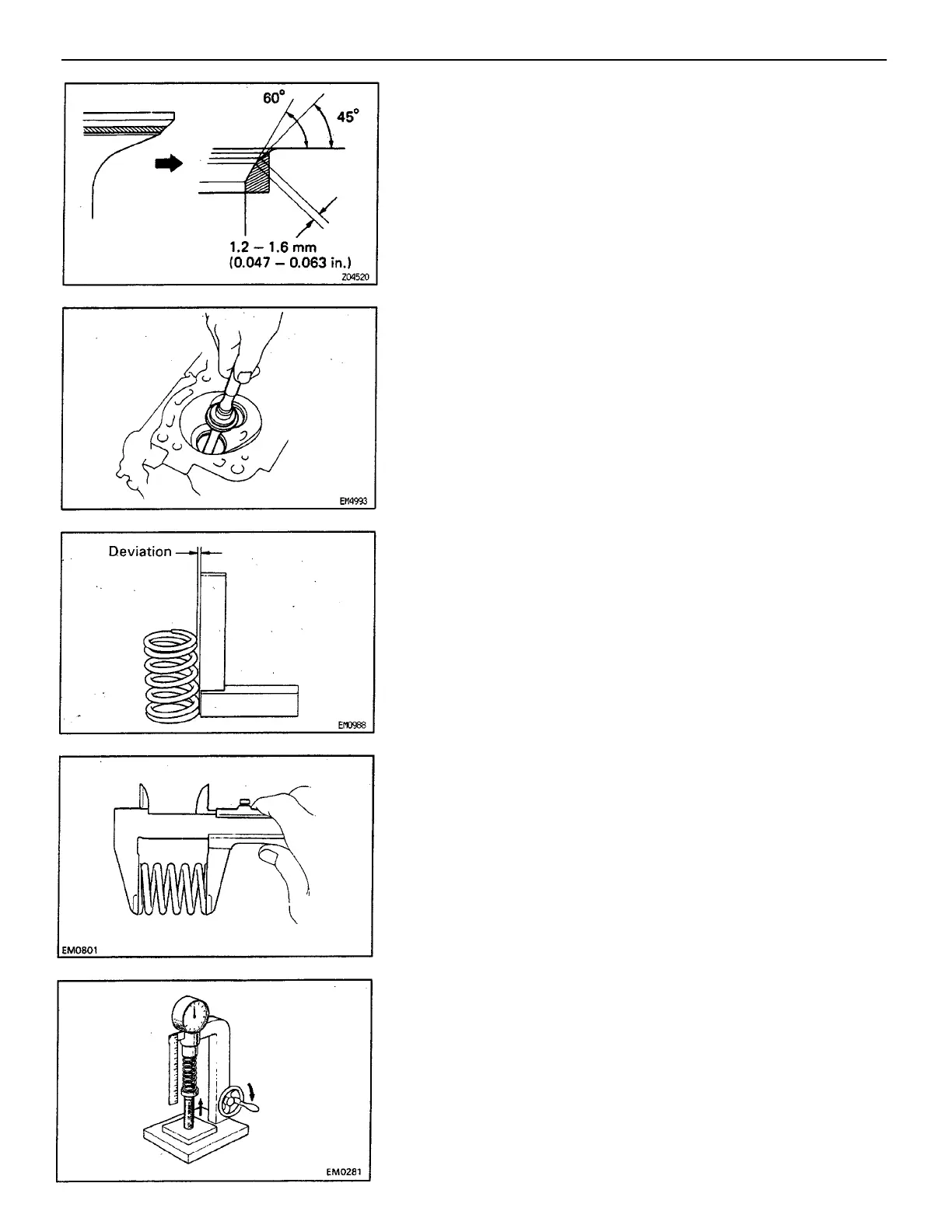

(b) Using a vernier caliper, measure the free length of the

valve spring.

Free length:

46.50 mm (1.8307 in.) for white painted mark

47.01 mm (1.8508 in.) for green painted mark

If the free length is not as specified, replace the valve

spring.

(c) Using a spring tester, measure the tension of the valve

spring at the specified installed length.

Installed tension:

242 – 268 N (24.7 – 27.3 kgf, 54.5 – 60.2 lbf)

at 40.0 mm (1.575 in.)

If the installed tension is not as specified, replace the

valve spring.

(d) Hand–lap the valve and valve seat with an abrasive

compound.

(a) After hand–lapping, clean the valve and valve seat.

(2) If the seating is too low on the valve face, use

60 and 45 cutters to correct the seat.

–ENGINE ENGINE MECHANICAL

EG2–69

Loading...

Loading...