9. Configuring the process controller

By means of the process controller, a process variable can be regulated, for instance the

pressure of a pump. The process controller is also referred to as "PID controller" (PID

controller = proportional, integral and differential controller).

The process controller is part of a closed control loop. The variable to be influenced

(controlled variable) is measured continuously by means of a sensor and supplied to the

inverter as an analog signal (actual value) which, in the inverter, is then compared to the

reference value (setpoint). The system deviation resulting therefrom is supplied to the

process controller which, on this basis, decelerates or accelerates the motor speed

according to the desired dynamic performance of the control loop, so that, for instance, a

pump always generates the desired pressure.

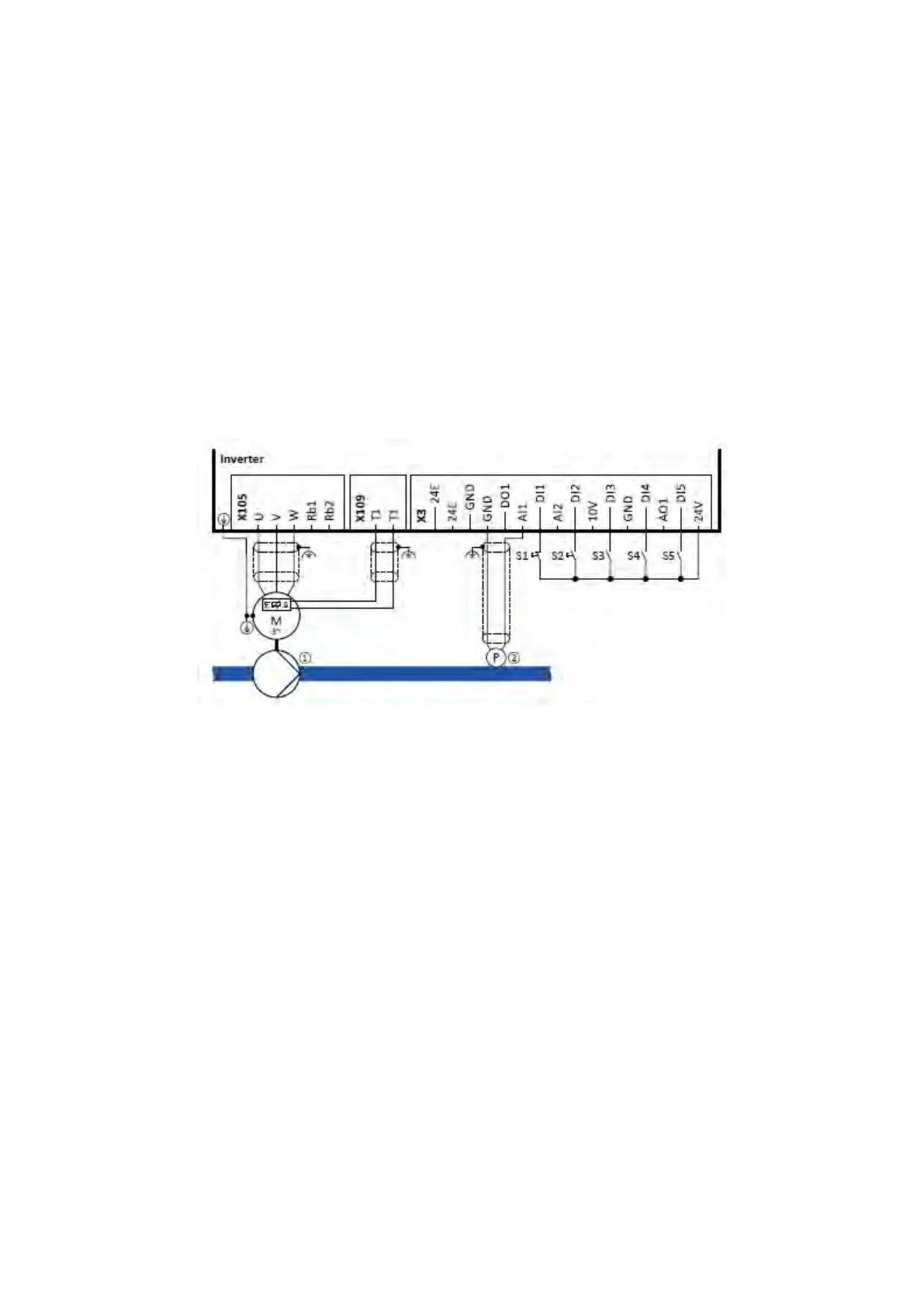

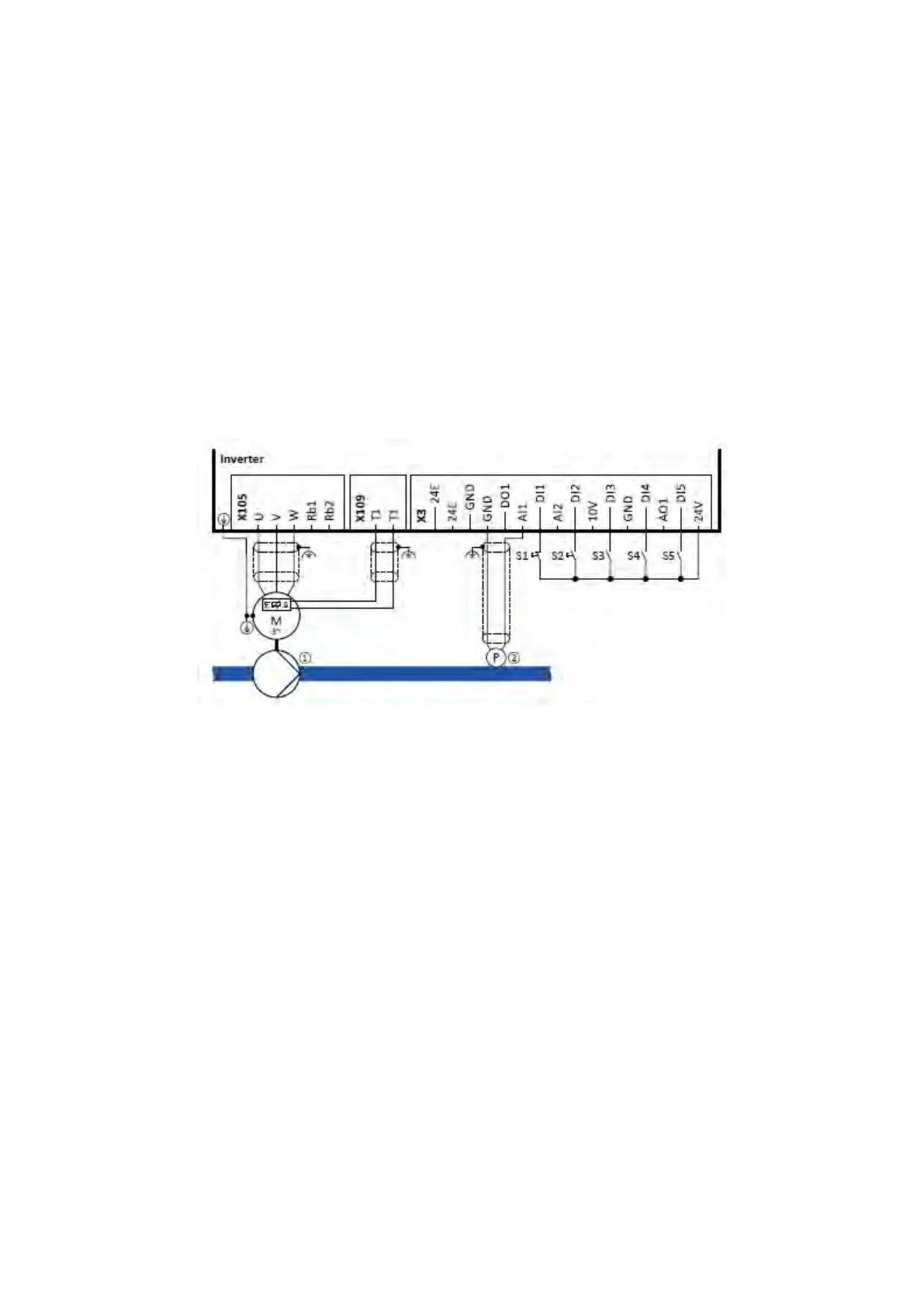

Connection plan (example)

The following sample connection plan shows the control of a pump

①

. The feedback of

the variable (here: pressure) takes place via a pressure transducer

②

connected to the

analog input 1.

The digital inputs can be used to activate functions of the process controller. The specific

assignment of the digital inputs and type of the contacts (switches or buttons, normally-

closed contacts or normally-open contacts) depends on the application.

General information on the setting

• The basic setting of the process controller is described in the following subchapter.

Basic process controller settings

233

• Optionally, the motor can be put into an energy-saving idle state if no power is

required.

Process controller idle state

239

• The rinsing function which can be activated in addition accelerates the motor in idle

state to a defined speed at regular intervals. The rinsing of a pipe system with a pump

that has been in an inactive state for a longer period is a typical application. Process

controller rinse function

240

Loading...

Loading...