346 01-6203-01R3, CG Drives & Automation

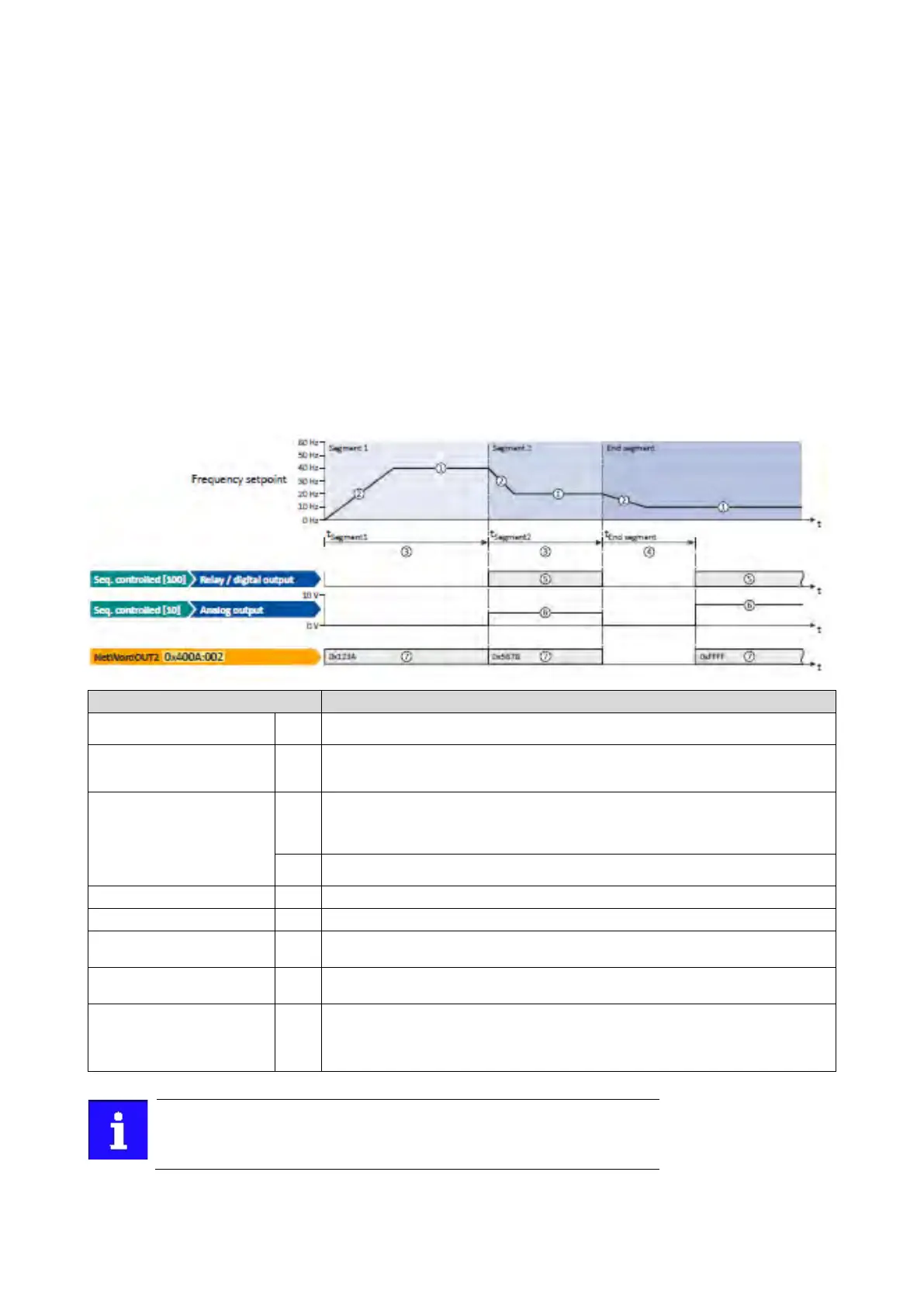

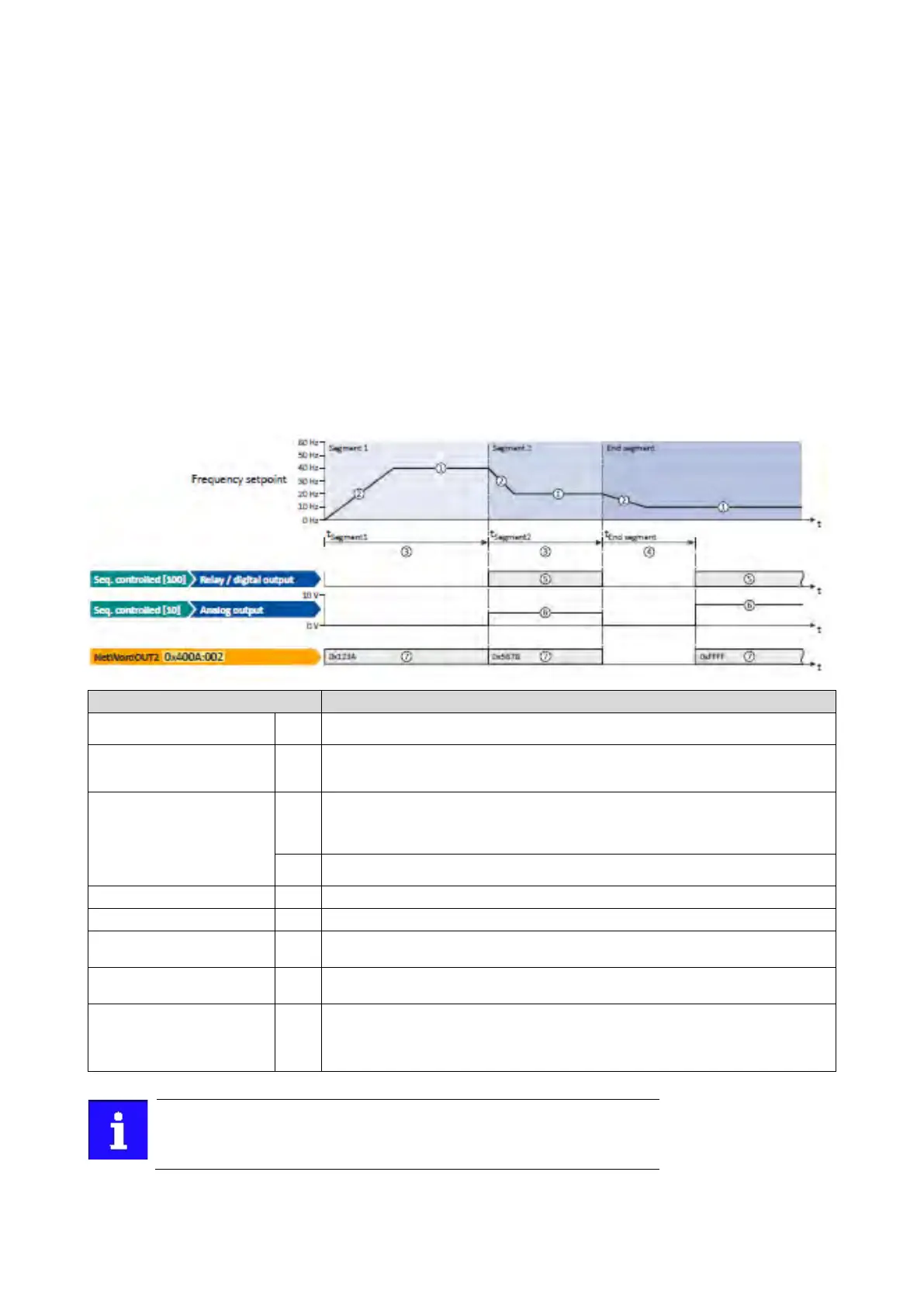

11.1. Segment configuration

Each step of a sequence can call a "segment". A segment contains, among other things

preset setpoints (speed setpoint, PID control value, torque setpoint), a combined

acceleration/deceleration for the speed setpoint and optionally a configuration for the

digital and analog outputs.

Details

As a total, 8 segments and one end segment can be configured.

• The settings are only effective if a sequence is active and the respective segment is

executed.

• Not all settings are relevant for all operating modes. If, for instance, the PID control is

not

used at all, no PID setpoint needs to be set for the segment.

• The following figure shows the segment settings relevant for the operating mode

0x6060 (P301.00) = "MS: Velocity mode [-2]".

• The table below contains a short overview of the possible settings for each segment.

①

Only relevant for the operating mode 0x6060 (P301.00) = "MS: Velocity mode [-2]". direction of

rotation according to sign.

Acceleration/deceleration

②

Only relevant for operating mode 0x6060 (P301.00) = "MS: Velocity mode [-2]". The set time

refers to the acceleration from standstill to the set maximum frequency. The deceleration is

effected with the same ramp.

③

Meaning for segment 1 ... 8:

Runtime for the segment after the expiry of which it is switched over to the next step of the

sequence. Only relevant for Sequencer mode 0x4025 (P800.00)

= "Time operation [1]" or "Time &

④

Meaning for end segment:

Delay time for activating the output states configured for the end segment.

⑤

Optionally: Set digital outputs to a certain level for the execution time of the segment.

⑥

Optionally: Set analog outputs to an adjustable voltage value for the execution time of the segment.

Only relevant if the PID control in 0x4020:001 (P600.01) is activated.

Configuring the process controller

232

Only relevant for operating mode 0x6060 (P301.00) = "MS: Torque mode [-1]".

Torque control w/ freq. limit

147

⑦

Optionally: Set NetWordOUT2 data word for the execution time of the segment to an adjustable

value. The NetWordOUT2 data word 0x400A:002 (P591.02) can be mapped to a network register to

transfer the set value as process date.

Further process data

191

In the following, all parameters relevant for the segment configuration are given.

If the sequencer is active, write accessed to all parameters are blocked that

concern the active segment configuration!

Loading...

Loading...