Operation

240

Pos: 55.119 /Übersc hriften/Überschr iften 3/K-O/Netzroll e einlegen @ 298\mod_1412765 877831_78.doc x @ 2335075 @ 2 @ 1

11.15 Inserting Net Roll

Pos: 55.120 /BA/Sic herheit/7. Gefahrenhin weise alt/Rundba llenpresse/Gefahr Öl auf Bindegarn @ 37\mod_1264 496122520_78.docx @ 3 41340 @ @ 1

CAUTION! – Contamination of the twine and tying mechanism by oil and grease

Effect: Machine damage and problems when unrolling twine

• The twine, twine tensioner and eyes must not be contaminated by oil or grease.

• The parts of the tying unit through which twine or net run must not be contaminated by oil or

grease.

Pos: 55.121 /BA/Sic herheit/7. Gefahrenhin weise alt/Rundba llenpresse/Gefahr Bi ndung eine Person @ 298\mod_1 412762562814_78.d ocx @ 2334813 @ @ 1

WARNING!

Risk of injury due to unexpected movement of a machine component.

• The net may only be inserted by one person.

• Make sure that there is no other person in the range of movement of the machine.

Pos: 55.122 /BA/Bedienu ng /Rundballenpresse/ Netz-Garnbind ung/Netzrolle einle gen CF/CV @ 74\mod_130874991 8367_78.docx @ 657820 @ @ 1

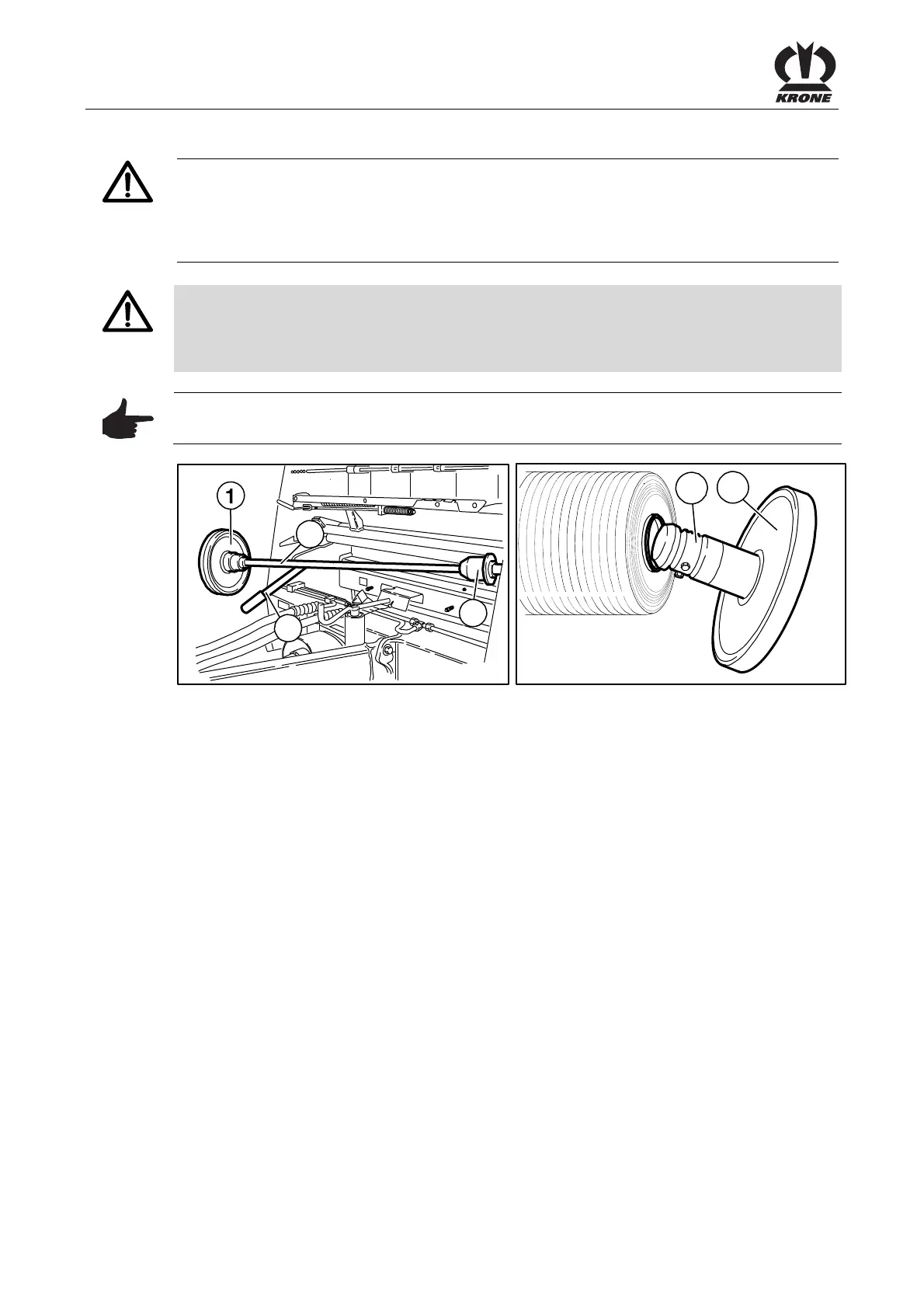

Note

The starting end of the net roll must point towards the machine and be pulled out from the top.

VP-2-074

2

4

3

RBV05360_1

1

5

Fig. 181

The preparations and insertion of the twine roll must be accomplished with machine at standstill:

• Switch off tractor P.T.O. shaft

• Switch off tractor engine

• Raise the lever (2)

• Swing the brake disc (1) with the net roll mounting shaft (3) forwards

• Detach the brake disc (1)

• Slide the net roll onto the net roll mounting shaft (3) and the support (4)

• Slide the brake disc (1) and cardboard tube clamp (5) counterclockwise into the cardboard

tube and then onto the net roll mounting shaft as far as possible

Pos: 55.123 /Layout Mod ule /---------- -----Seitenumbruc h------------- --- @ 0\mod_1196175311226_ 0.docx @ 4165 @ @ 1

Loading...

Loading...