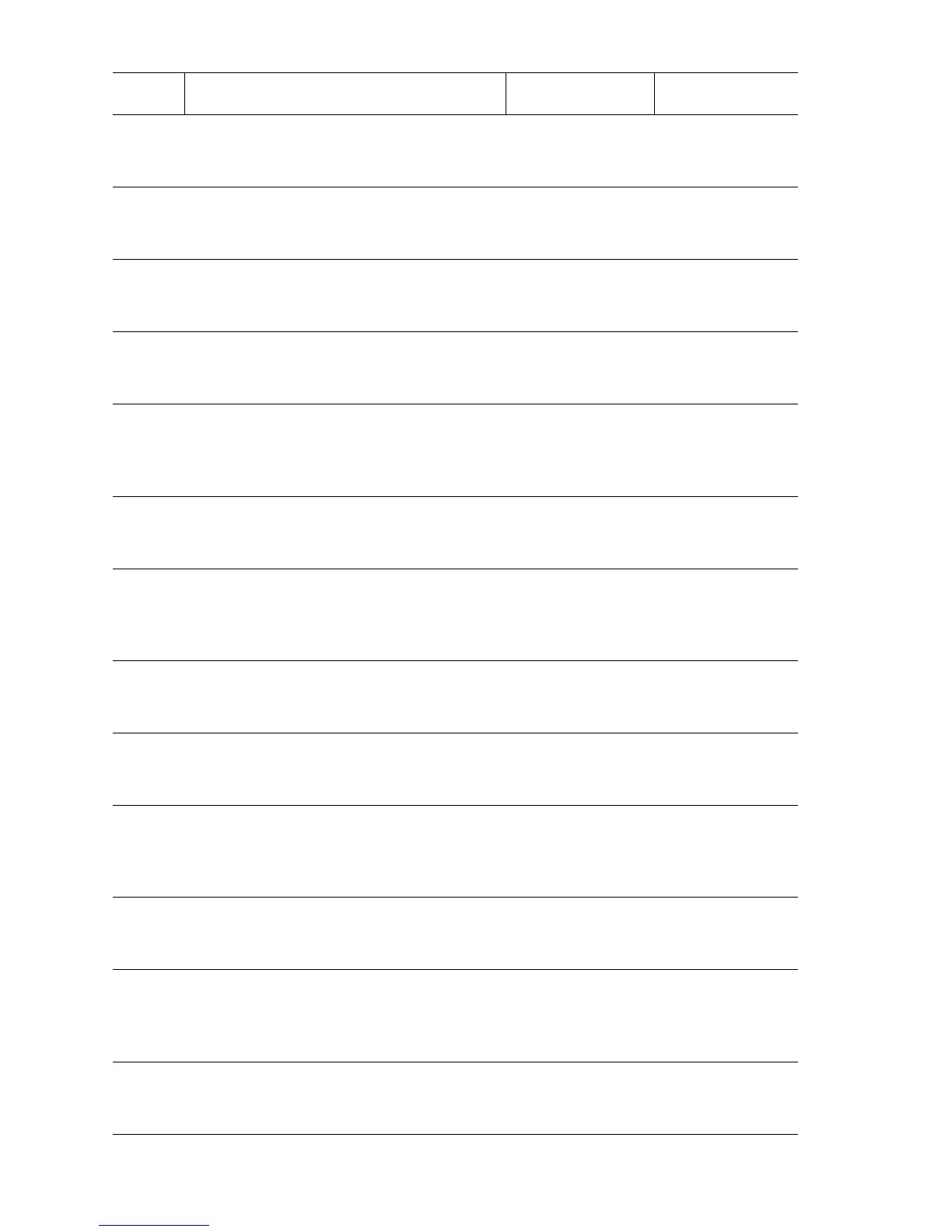

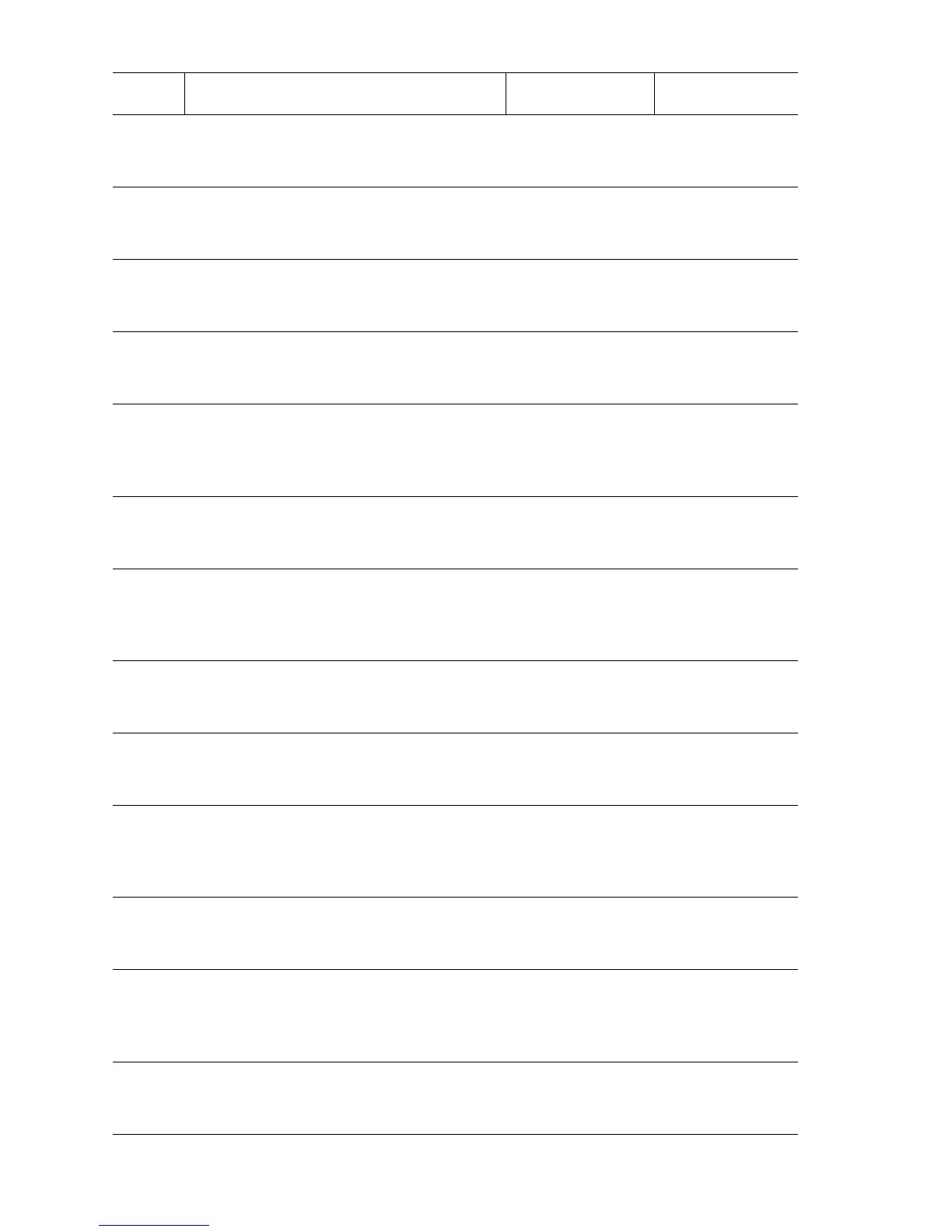

3-50 Phaser 5500 Printer Service Manual

4

Check the Inv Roller.

Is the INV Roller worn or contaminated

with paper dust?

Clean or replace

the INV Roller.

Go to Step 5.

5

Check the drive transmission.

Does the INV Roller and gears rotate

smoothly?

Go to Step 6. Restore proper

operation.

6

Check the OCT Roller.

Is the OCT Roller worn or contaminated

with paper dust?

Clean or replace

the OCT Roller.

Go to Step 7.

7

Check the drive transmission.

Does the OCT Roller and gears rotate

smoothly?

Go to Step 8. Restore proper

operation.

8

Test the Exit 2 Motor.

Run the Service Diagnostics Exit 2 Motor

tests.

Does the Exit 2 Motor operate properly?

Go to Step 17. Go to Step 9.

9

Check the Exit 2 Motor connections.

Are P/J208, P/J606A and P/J433

connected?

Go to Step 10. Connect P/J208,

P/J606A and P/

J433.

10

Check continuity between the Exit Motor

and Exit PWB.

Is there continuity on each wire

between P/J208 <=> P/J433?

Go to Step 11. Repair the wiring.

11

Check for +24 V to the Exit 2 Motor.

Is there +24 V across P208-5 (+) <=>

ground?

Replace the Exit 2

Motor

(

page 3-104).

Go to Step 12.

12

Check the connection between the Exit

PWB and Engine Logic Board,

Are P/J431 and P/J421 connected?

Go to Step 13. Connect P/J431

and P/J421.

13

Check continuity between the Exit PWB

and the Engine Logic Board.

Is there continuity on each wire

between P/J431 <=> P/J421?

Go to Step 14. Repair the wiring.

14

Check the connection between the Exit

PWB and the LVPS.

Are P/J430 and P/J526 connected?

Go to Step 15. Connect P/J430

and P/J526.

15

Check continuity between the Exit PWB

and the LVPS.

Is there continuity on each wire

between P/J430 <=> P/J526?

Go to Step 16. Repair the wiring.

16

Check for +24 V to the Exit PWB.

Is there +24 V across P/J430-1 (+) <=>

ground?

Replace the Exit

PWB (

page 8-88).

Replace the

LVPS

(

page 8-92).

E8-2 Duplex Area Jam Troubleshooting Procedure (Continued)

Step Actions and Questions Yes No

Loading...

Loading...