Print-Quality Troubleshooting 5-37

Repeating Defects

Recurring marks, spots, lines, or voids.

Initial Actions

■ Check that the paper is clean, dry, and meets specifications.

■ Inspect the paper path for items, such as staples, paper clips, and paper

scraps.

■ Check the installation of the Drum Cartridge.

■ Check that the Drum Cartridge ground contacts are clean.

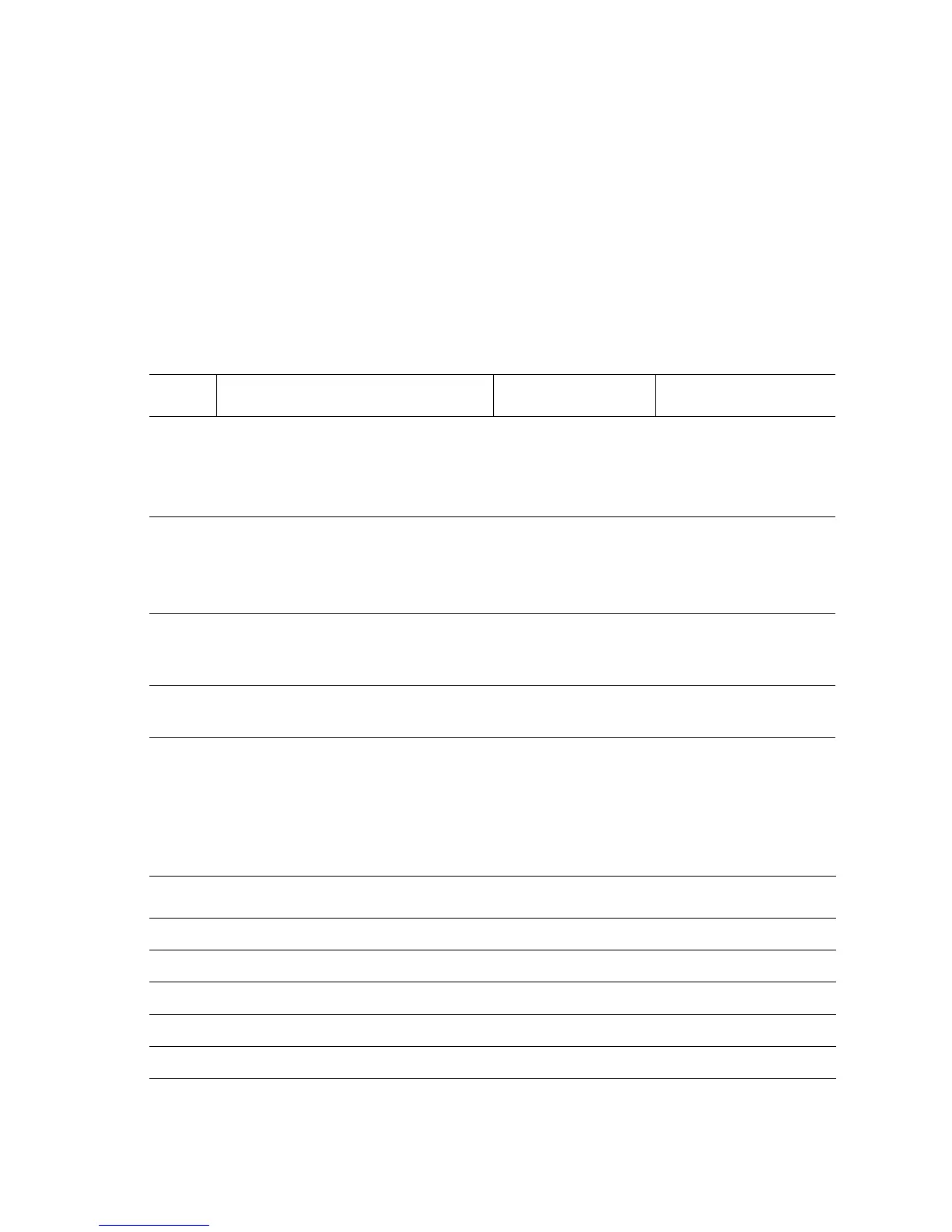

Xerographic Component Specifications

The following table lists measurements of critical printer components. Refer to these

measurements when diagnosing a repeating print-quality problem.

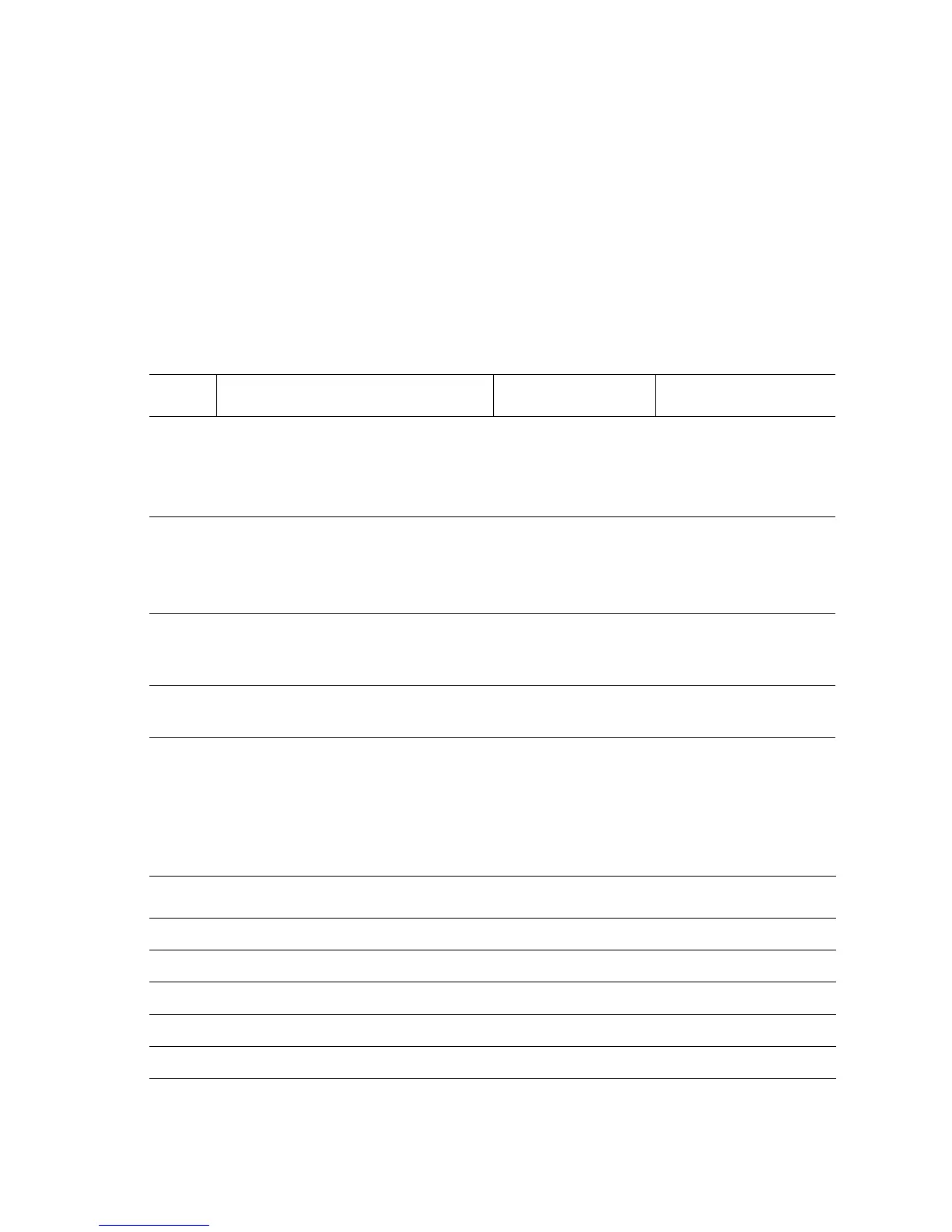

Repeating Defects Troubleshooting Procedure

Step Actions and Questions Yes No

1

1. Replace paper with new paper.

2. Print a test print.

Do the repeating defects still

appear?

Go to Step 2. Problem solved.

2

Do the defects occur every:

■ 44 mm (1.7 in.)

■ 56.5 mm (2.2 in.)

■ 94.2 mm (3.7 in.)

Install a new Drum

Cartridge.

Go to Step 3.

3

Do the defects occur every

58.7 mm (2.3 in.)?

Replace the

Transfer Roller

(page 8-44).

Go to Step 4.

4

Do the defects occur every:

78.5 mm (3.1 in.)?

Replace the Fuser

(page 8-76).

Component Circumference

Charge Roller (Drum Cartridge) 44.0 mm (1.7 in.)

Developer Roller (Drum Cartridge) 56.5 mm (2.2 in.)

Photoreceptor (Drum Cartridge) 94.2 mm (3.7 in.)

Transfer Roller (Door A) 58.7 mm (2.3 in.)

Fuser Heat Roller (Fuser) 78.5 mm (3.1 in.)

Loading...

Loading...