Cylinder block and crank connecting rod mechanisms

73

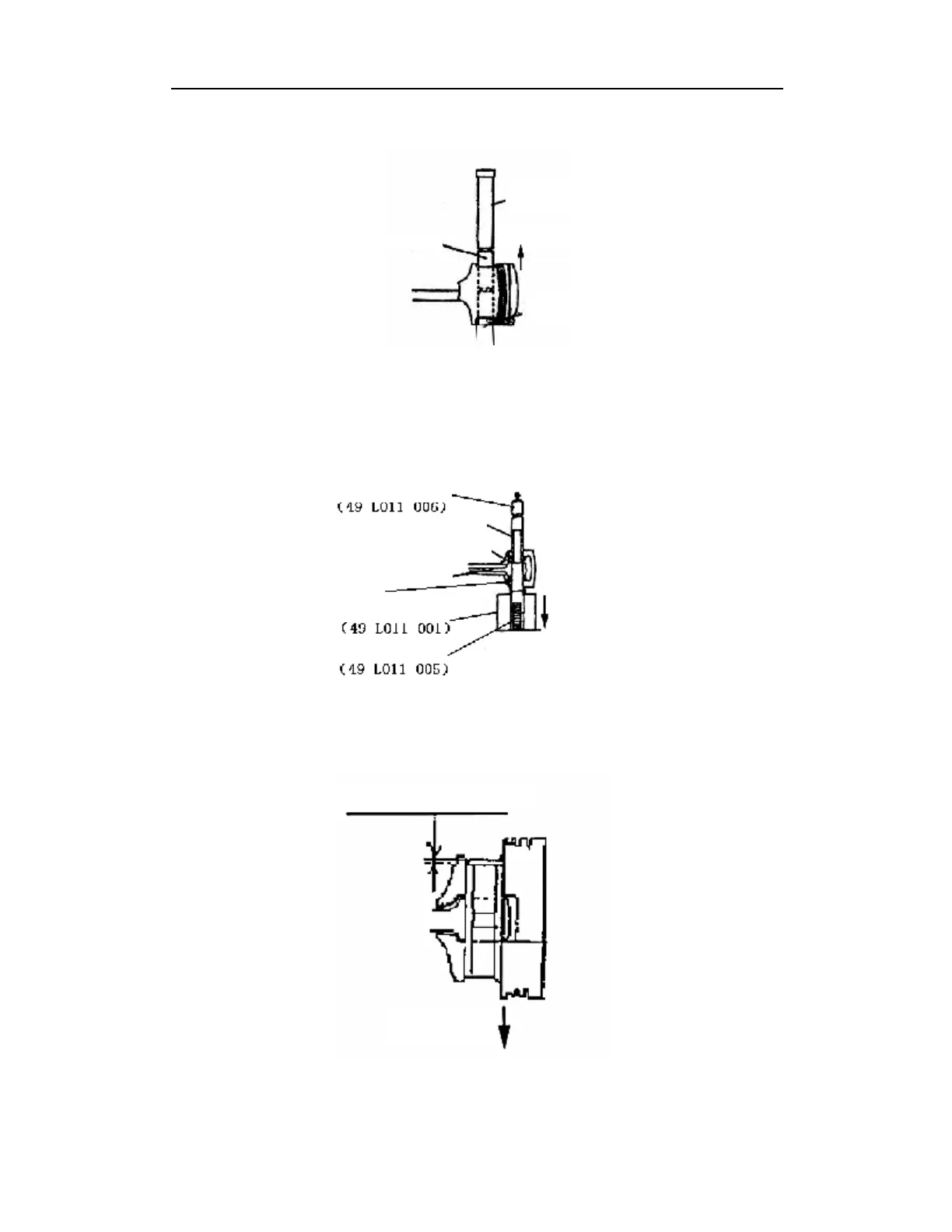

6. Insert the piston pin and the special tool fitted as per the 2

nd

step into the piston and

connecting rod as shown in Fig.,below;

7. Use a press to press in the piston pin into the piston and connecting rod until the

special tool no.2 (guide tube) gets in contact with the special tool (stop bolt).

8. While pressing in the piston pin, check the press-in pressure. If lower than the index,

replace the piston pin or connecting rod.

Pressure: 4.90~14.70kN(500~1500kgf, 1100~3300lbf)

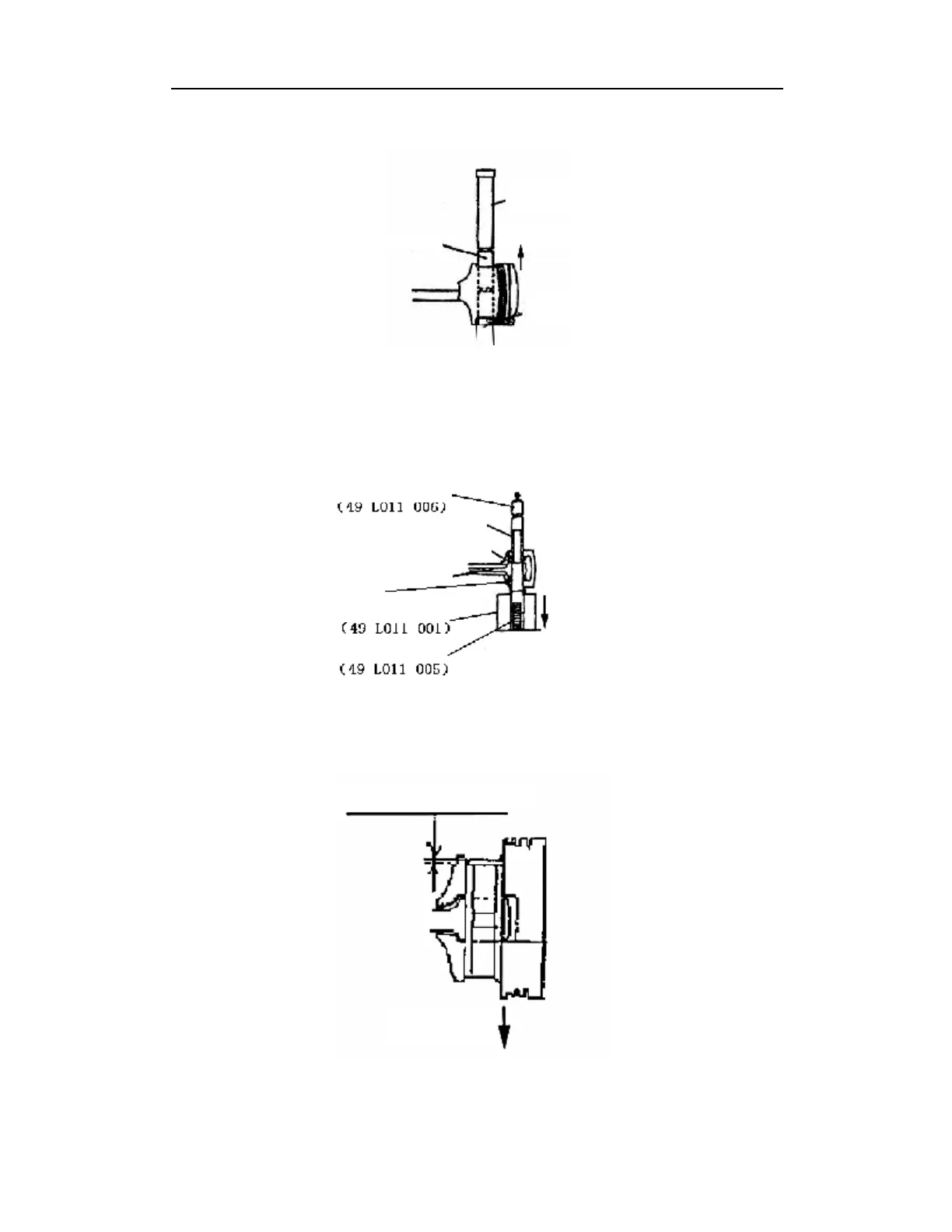

9. Check the pressed depth of piston pin. If it is out of the standard value, restart from

the 1

st

step.

Press-in depth of piston pin: 1.65~2.05mm{0.0650~0.0807in}

Special tool No.1

Piston pin assembling tool

Mark “F” of

piston side

Press-in depth of piston pin

Piston pin

Piston

Connecting

rod

The press-in

“F” of piston side

Piston pin assembling tool

Piston pin assembling tool

Piston pin

Mark “F” of piston side

Special tool No.2

Loading...

Loading...