Operation

Central lubricating system

343 / 564

6.23 Central lubricating system

The machine is fitted with a central lubricating system and has three lubricating cir-

cuits.

(1) Lubricating circuit 1 chassis

(2) Lubricating circuit 2 lifting beam only eccentric drive

(3) Lubricating circuit 3 lifter (not eccentric drive) and defoliator

All connected lubricating points are automatically supplied with grease. The lubricating

pump supplies the grease to the main distributors, the main distributors distribute the

grease to sub-distributors, and these supply it to the individual lubricating points. As

long as the lubricating pump is running, a stirring paddle is rotating in the grease reser-

voir and the R-Touch displays the icon . During operation, the lubricating pump in

basic setting is switched on for 21 minutes, then makes a pause for 60 minutes.

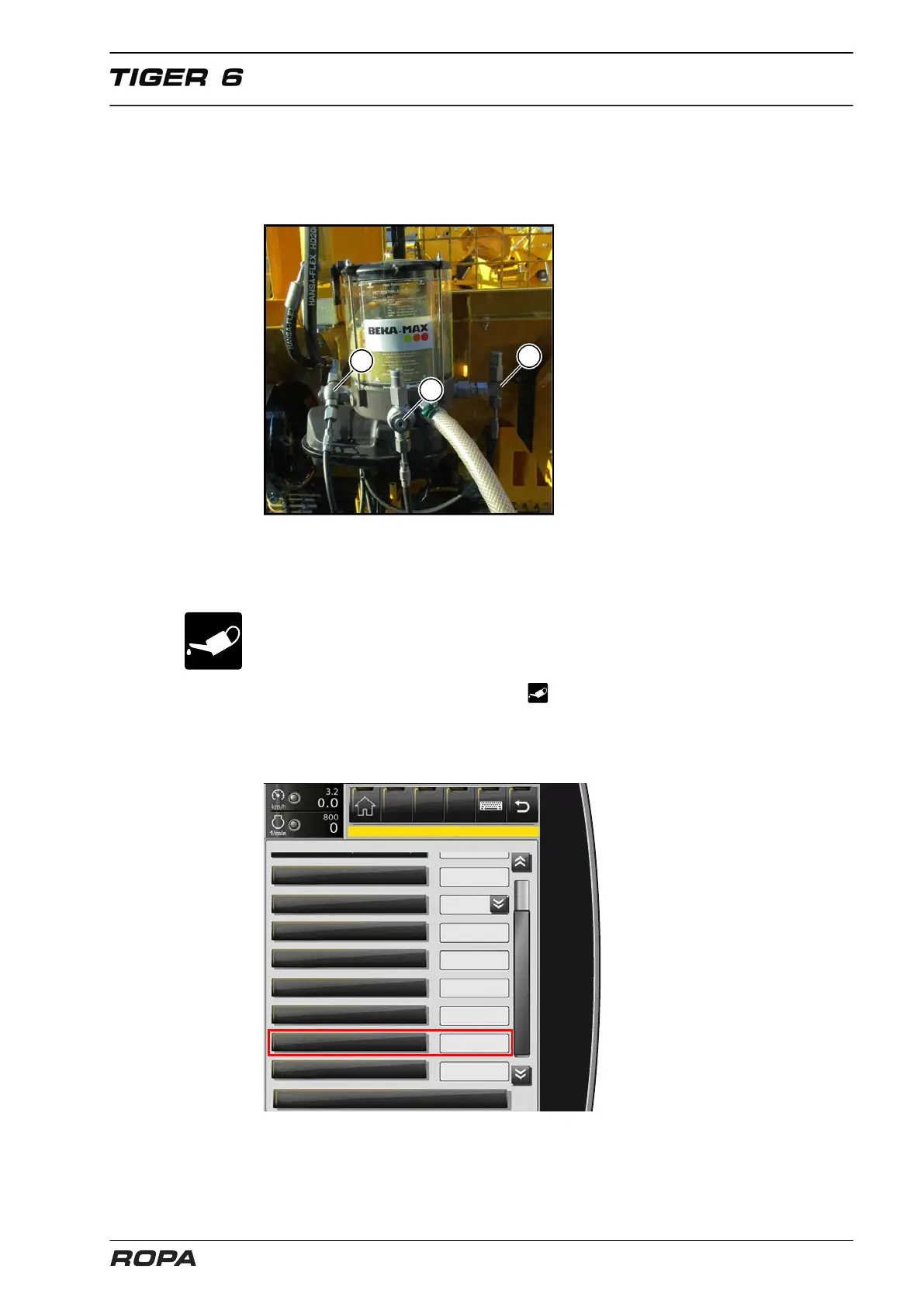

If necessary, this setting can be adapted at any time to individual requirements in the

menu "Main settings", submenu "Others", line "Lubricating time (min)".

Interval time windshield-wiper

Drive pedal damping "Road"

Drive pedal damping "Field"

Drive partial shutdown

Warning-limit fuel tank (%)

Greasing time (min)

AdBlue reserve warning %

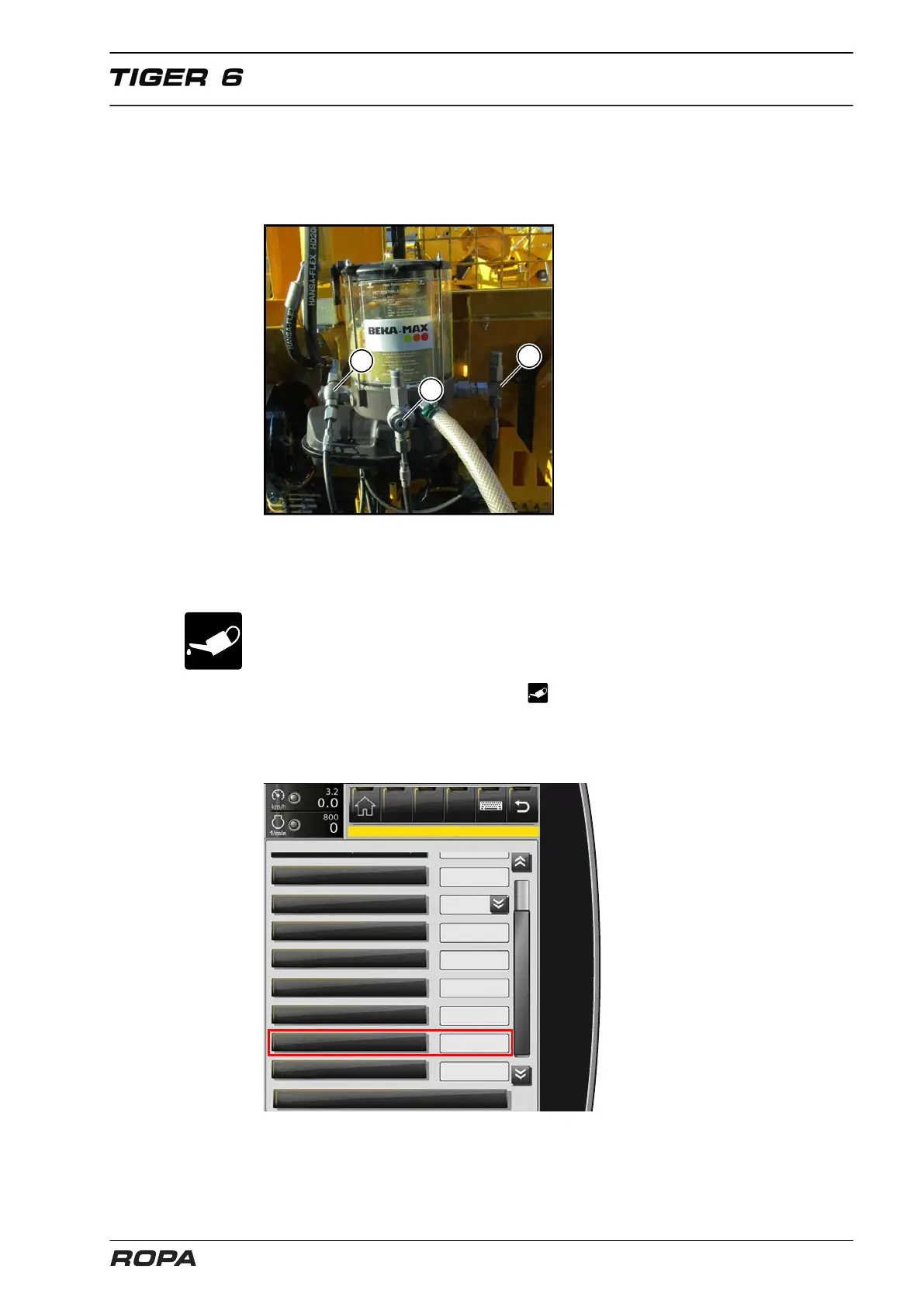

The 2 kg supply reservoir of the grease pump is filled up using the lever on the large

grease bucket. Never completely fill up the 2 kg supply reservoir of the grease pump.

Only fill up the supply reservoir for the grease pump for 90 %. In this way, you avoid

blocking of the ventilation pipe on the 2 kg supply reservoir.

Loading...

Loading...