Malfunction and Remedies

Central lubrication system – bleeding and removal of blocks

520 / 564

8.13 Central lubrication system – bleeding and removal of blocks

Lubricat-

ing pump

→

Main distributor

→

Sub-distributor

→

Lubricat-

ing point

During all work on the central lubrication system, make sure of utmost cleanliness. In

no case should dirt enter the lubrication system.

Should the grease reservoir inadvertently have been run empty, then the grease pump

must be bled. For this purpose, remove the main pipe from main distribution and

switch on the pump for so long until air-free grease emits from the main pipe. Screw a

lubricating nipple into the input of the main distributor and using the grease gun, pump

grease into the main distributor for so long until grease emits at the bearings. Then,

reconnect all pipes.

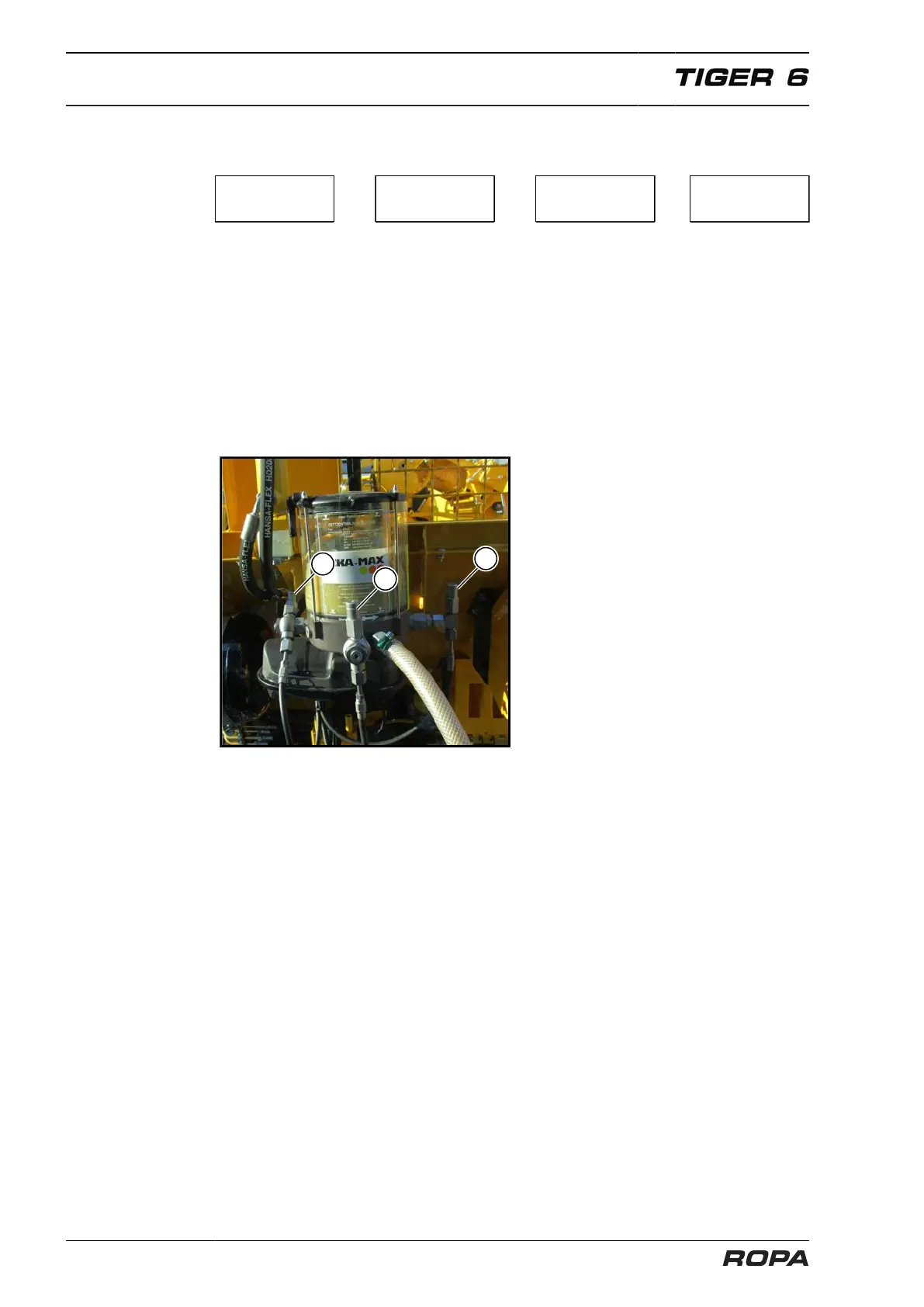

If the pipe system is blocked, then the grease will be pressed out at the safety valve

(1) (directly at the pipe output of the pump). To remove this block, proceed as follows:

(1) Safety valve

– Search for the blocked spot in the pipe system. Go along the stiffer grease pipe

from the lubricating pump through to the main distributor (the blocked pipe is stiffer

because it is under pressure) further to the corresponding sub-distributor and from

there to the blocked lubricating point. You can find a detailed plan in chapter 9.

– Disconnect the pipe from the distributor and screw a lubricating nipple into the cor-

responding (sub) distributor.

– Try to loosen the block strongly pressing grease into the distributor using the hand

lever grease gun.

– Proceed systematically: from the grease pump to the main distributor, from there to

the sub-distributor, etc..

– Once you determine that the line is permeable again, connect the line with the con-

sumer. Check the free passage by performing an intermediate lubrication.

– Shouldn't the method prescribed here lead you to any success, please contact your

ROPA service station.

Loading...

Loading...