Maintenance and Service

Axles

412 / 564

7.6.4 Differential gears 2nd rear axle

The first oil change is required after 50 operating hours, further oil changes must be

performed annually.

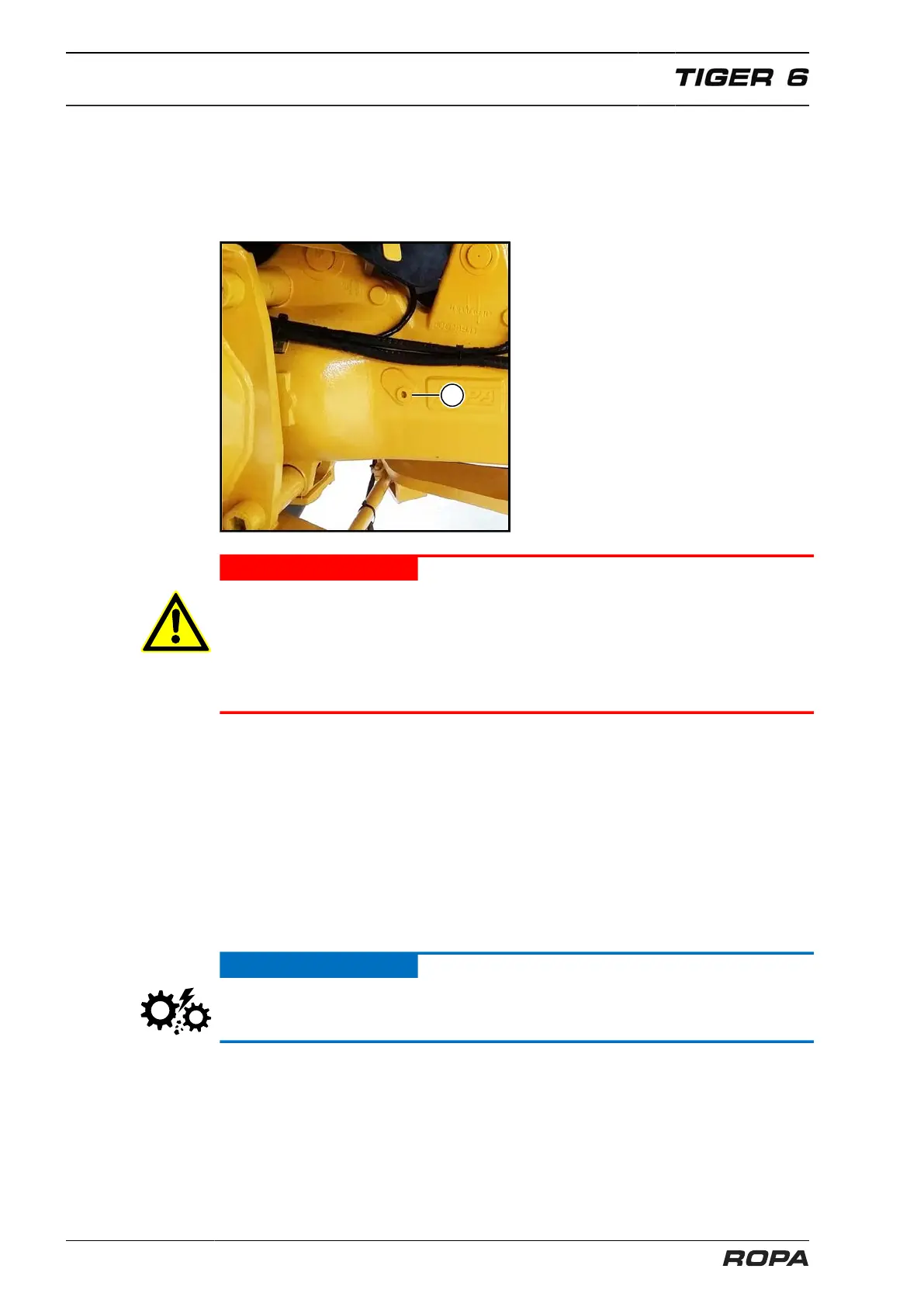

Oil filling opening and oil level control

screw (2) on the left front side of the axle.

DANGER

Injury hazard!

Hazard to life due to moving machine parts.

– Before oil change, each time stop the machine and switch off the engine.

– The machine must be secured against inadvertent starting of the engine.

– All maintenance and repair work may only be performed by trained personnel.

Proceed as follows for changing the oil:

– Change the oil only with gears warm after operation.

– Park the machine on level ground.

– Put an oil-resistant collecting vessel of sufficient size underneath.

– Turn off the oil drain screw of the differential gears. It is located at the bottom, at

the lowest part of the axle body.

– Open the oil level control screw and wait until the oil has drained completely.

– Reinsert the oil drain screw.

– Fill in oil through the oil filling opening for so long until the oil level reaches the

lower edge of the oil filling opening.

– Screw the oil level control screw in again.

ATTENTION

No multi-disk brake is mounted in this differential gears. To avoid any confusion, you

can also fill in oil with LS additives (LS = Limited Slip), as for the 1st rear axle.

Prescribed oil variants: Gear oil

API GL5, SAE 90

Filling volume: approx. 30 litres

Loading...

Loading...