Maintenance and Service

Diesel engine

385 / 564

7.1.4.4 Remarks of ROPA on the coolant (general information)

Normally, coolant consists of water and corrosion protection/antifreeze agent. The cor-

rosion protection/antifreeze agents (ethylene glycol with corrosion inhibitors) have the

following tasks in the cooling system:

Sufficient corrosion and cavitation protection for all components of the cooling sys-

tem.

Lowering of the freezing point (frost protection).

Raising of the boiling point.

For reasons of corrosion protection, about 50 vol.-% corrosion protection/antifreeze

agents must be added to the cooling liquid, if the expected environmental tempera-

tures do not require even higher concentration. This concentration (50 vol.-%) offers

antifreeze protection up to about -37°C. A higher concentration is only sensible for

even lower environmental temperatures. Even in case of extremely low environmen-

tal temperatures, do not use more than 55 vol.-% of corrosion protection/antifreeze

agents, since the maximum frost protection is achieved then, and greater share in the

mixture reduces frost protection and worsens heat dissipation (55 vol.-% corresponds

to frost protection up to about -45°C). If these coolant regulations are not complied

with, then corrosion and damage to the cooling system are inevitable. Adding of cor-

rosion protection/antifreeze agents raises the boiling point. Increased pressure further

increases the boiling temperature. Both physics coherences are used in modern cool-

ing systems – the maximum coolant temperature is increased without increasing the

hazard of boiling. Corresponding to the higher temperature level, the cooling perfor-

mance increases.

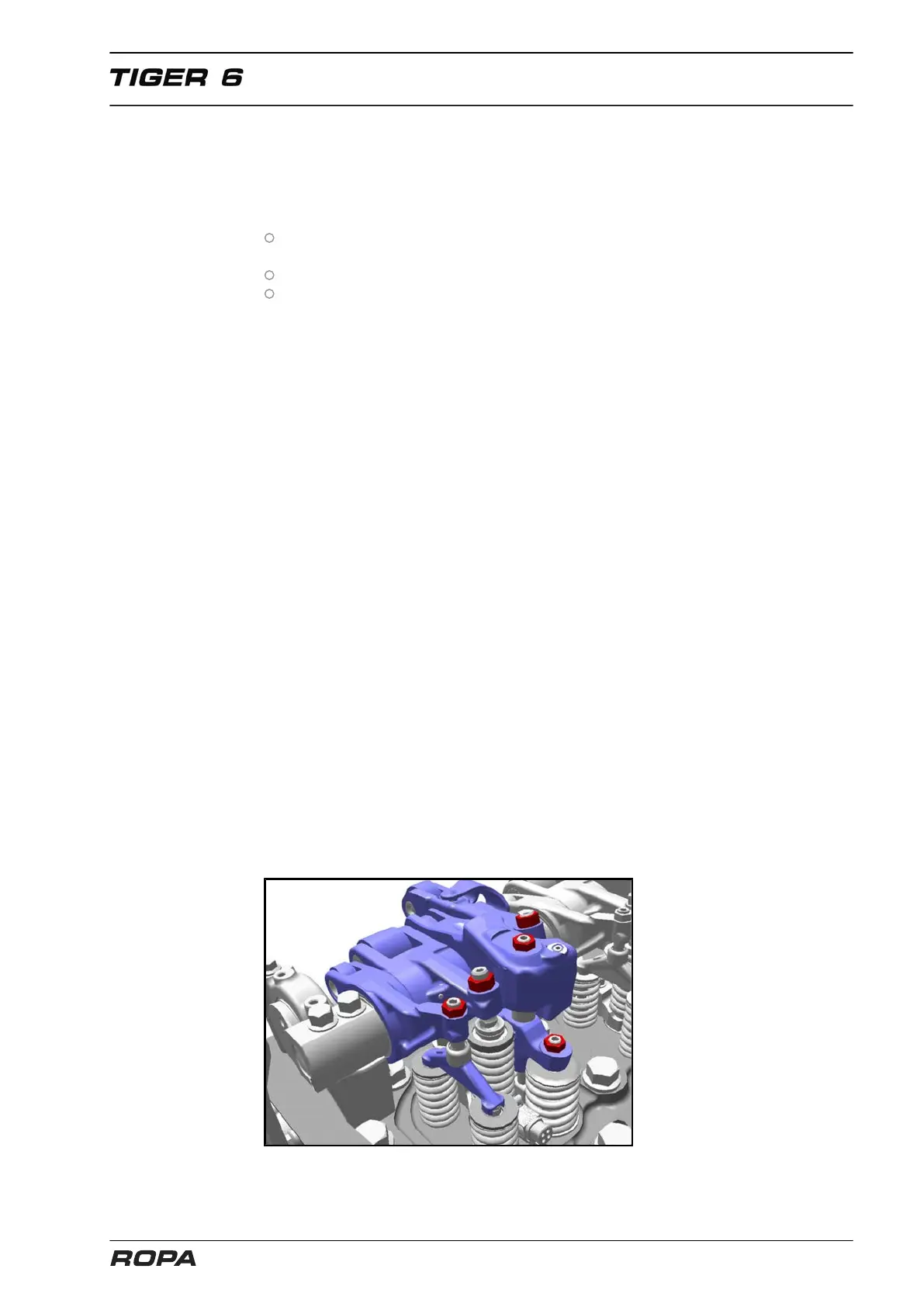

7.1.5 Valve clearance adjustment

Checking respectively adjusting of valve-clearance is required after the

first 1000 operating hours and then once annually respectively every

2000 operating hours. This work may only be performed by people expressly autho-

rised for this work by Volvo.

Valve clearance for cold engine:

0.30mm +/- 0.05mm Inlet valves

0.60mm +/- 0.05mm Outlet valves

3.70 - 4.00 mm VCB (engine brake)

(see Volvo workshop manual)

Valve drive with VCB (Volvo Compression Brake)

Loading...

Loading...