Maintenance and Service

Infeed conveyor

443 / 564

7.10 Infeed conveyor

ATTENTION

All rollers of the infeed conveyor must be checked daily for operational function and

damage. Blocked or damaged rollers must be immediately exchanged for new rollers.

Infeed conveyor and rollers must also be cleaned daily of jammed stones and other

foreign objects.

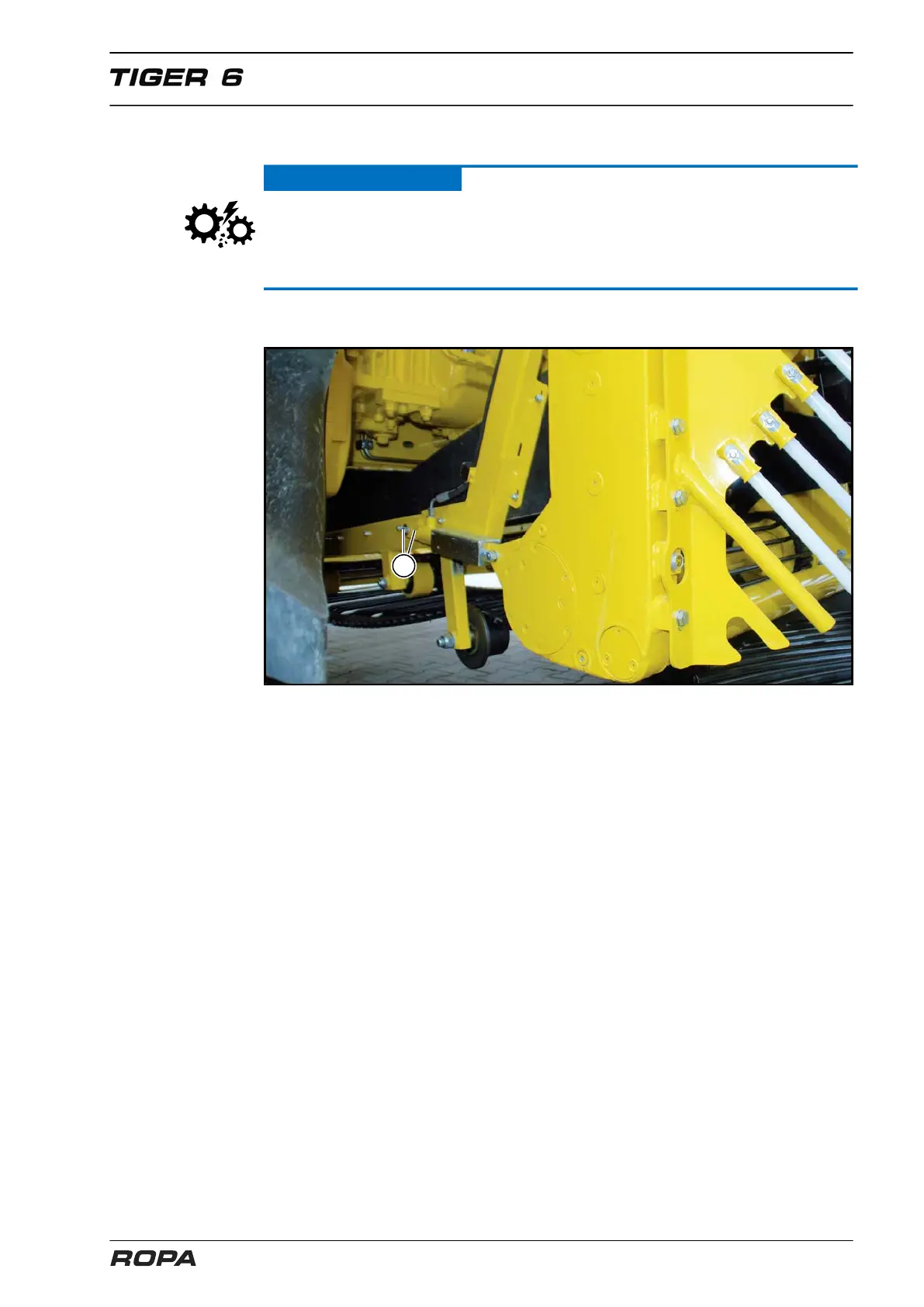

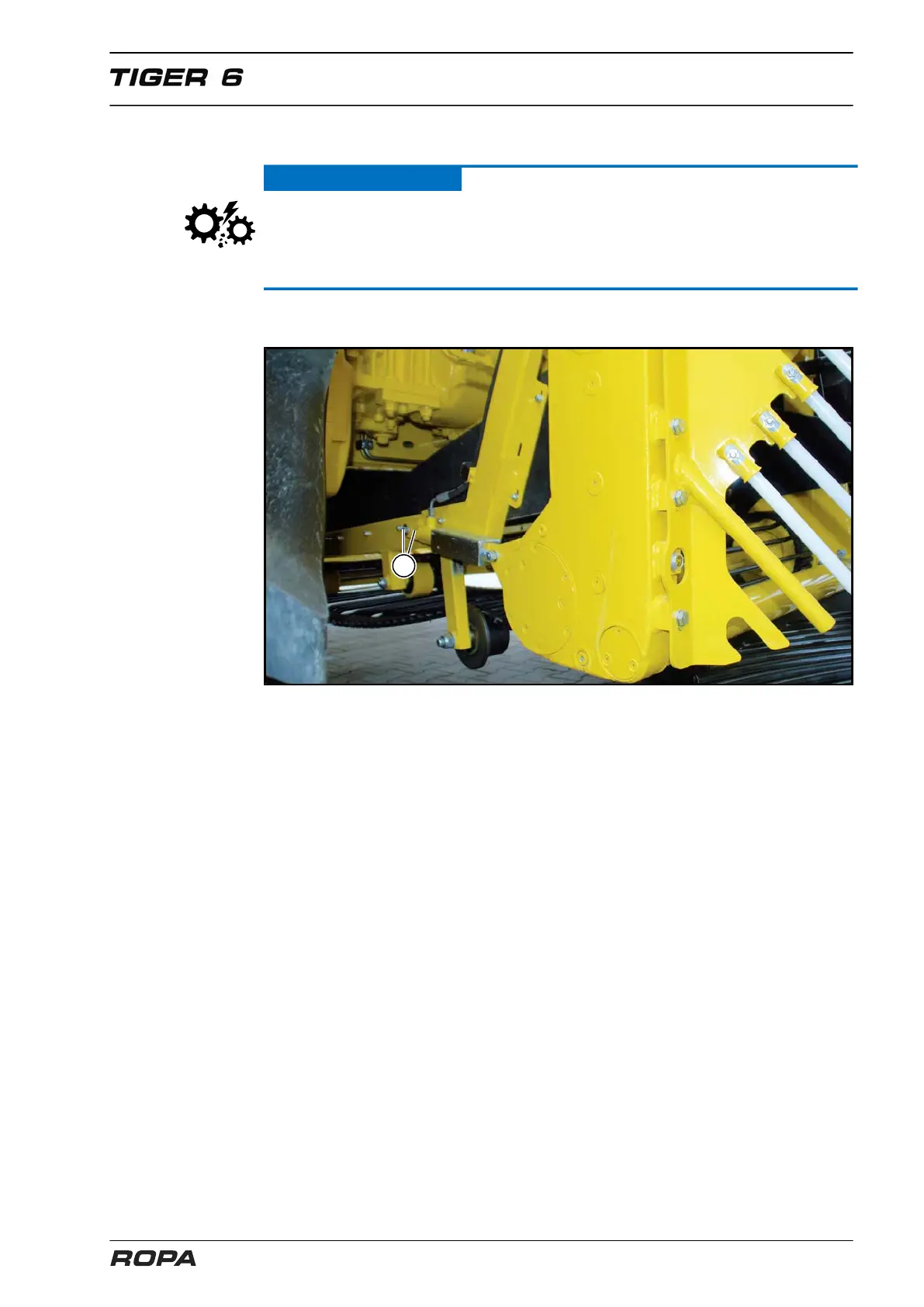

7.10.1 Tension

(1) Bores

The straining chain of the infeed conveyor is driven by rubber-coated friction wheels.

So that the conveyor does not slip on the slippery drive wheels, it is hydraulically ten-

sioned by movement of the drive shaft.

When the diesel engine is running, the infeed conveyor is pretensioned by the

hydraulic system with low pressure. When the drive is switched on, the pressure from

the infeed conveyor drive generates the required operating tension for the infeed con-

veyor. In case of need, pretensioning of the infeed conveyor may be additionally,

mechanically modified (2 bores (1) in the flap).

The flap must be mounted so that the cylinder does not extend to the stop.

Loading...

Loading...