FuelsManager Defense

302 Administrator Manual

This correction is only applied to float gauges. It does not apply to non-contact

measurement devices.

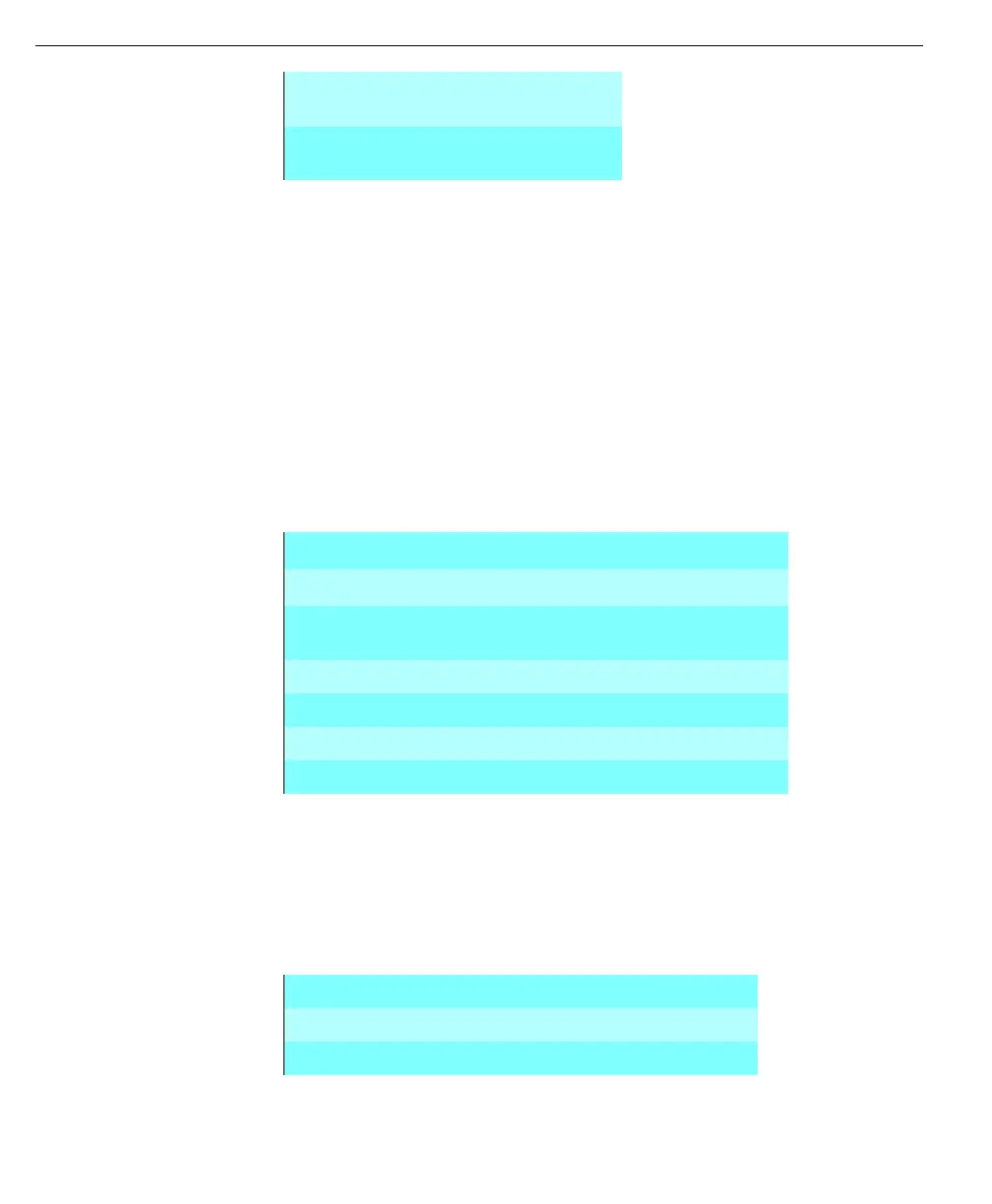

Corrected height = measured height + Δh

(b)Thermal correction. This is necessary to account for the thermal expansion of

the tank or stilling well and the gauge wire. For a float gauge this will be carried out

in addition to the buoyancy correction.

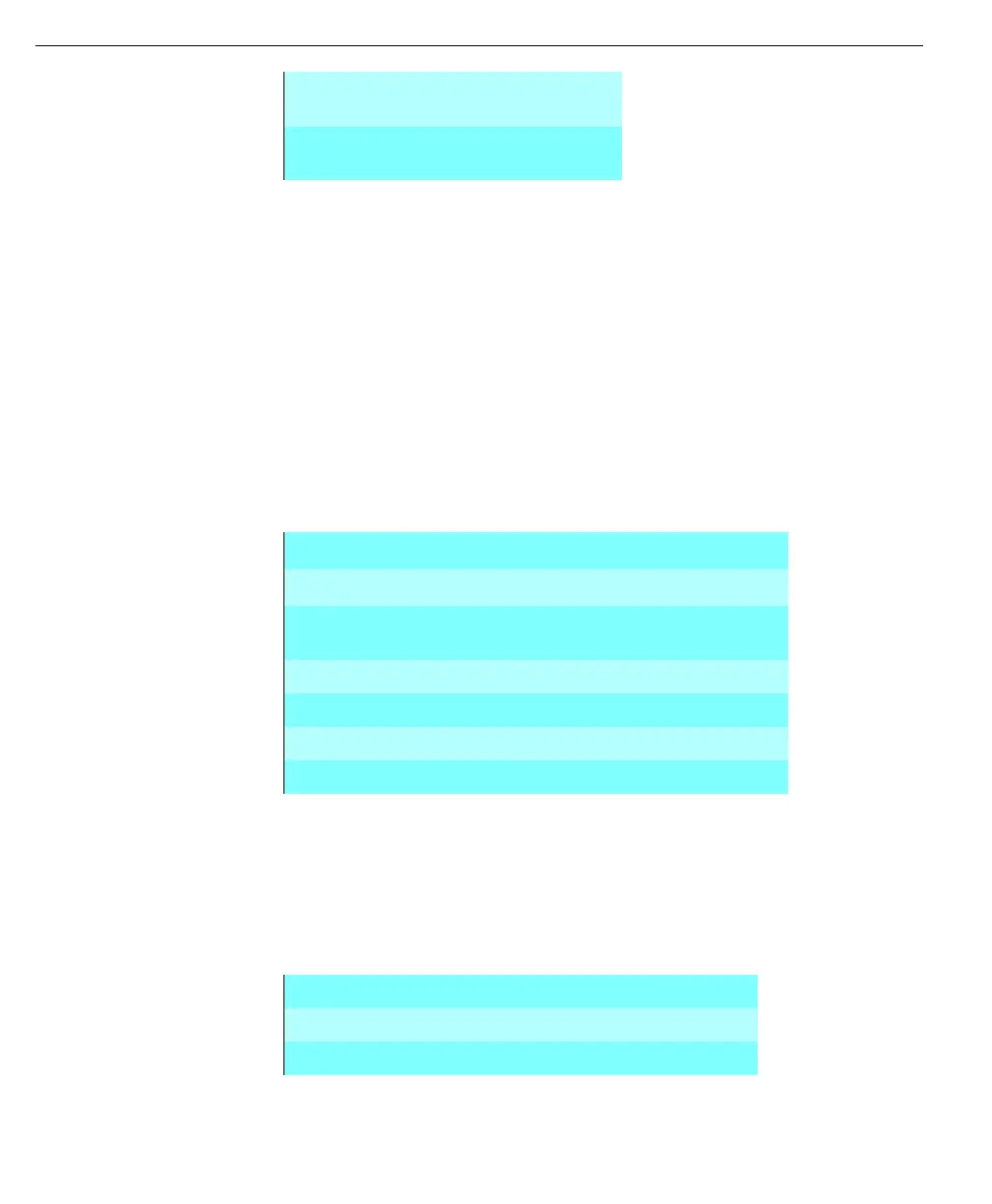

The correction is:

Where:

Note! When a float gauge is used

H is the value after the buoyancy

correction has been carried out.

The use of as the coefficient of thermal expansion of the tank or stilling well

depends upon the mounting of the gauge. When the gauge is mounted on the

tank, or on the well but this is not rigidly fixed to the tank base, the coefficient of

the tank is used. The well coefficient is only used when the gauge is mounted on

the well and this is rigidly fixed to the tank bottom. In this case movement of the

gauge, relative to the bottom of the tank, is governed by stilling well expansion and

contraction.

Typical values of thermal expansion coefficients are:

The corrected level (HC) is given by:

p

1

density of liquid at the time of

calibration

p density of liquid at the time of

gauging

Δh

2

correction to gauge readout for thermal expansion

α

w

= coefficient of thermal expansion of gauge wire /°C

α

m

= coefficient of thermal expansion of gauge mounting

(tank or well) /°C

TV = average vapor temperature°C

TL = average liquid texnperature°C

HT = total height of mounting (tank or well) in mm

H = depth of liquid in mm

Δh

2

αw 15 TV–()HT H–()α

m

15 TV–()HT H–()– α

m

15 TL–()H–=

Aluminium 0.000023 /°C

Mild steel 0.000011 /°C

Stainless steel 0.000017 /°C

HC H ΔH

1

ΔH

2

++=

Loading...

Loading...