INTRODUCTION

2

AV7000 LINEAR CAMERA

Field Procedure Quick Cross Reference:

• “Setting Up the S-60 Photocell” on page 373

• “Setting up The RangeFinder” on page 389

• “Setting Up the DS2 Light Curtain” on page 374

• “Setting Up the DK502 (S85) Distance Kit” on page 375

• “Setting up the AS1 AreaScan” on page 373

READING STATION OVERVIEW

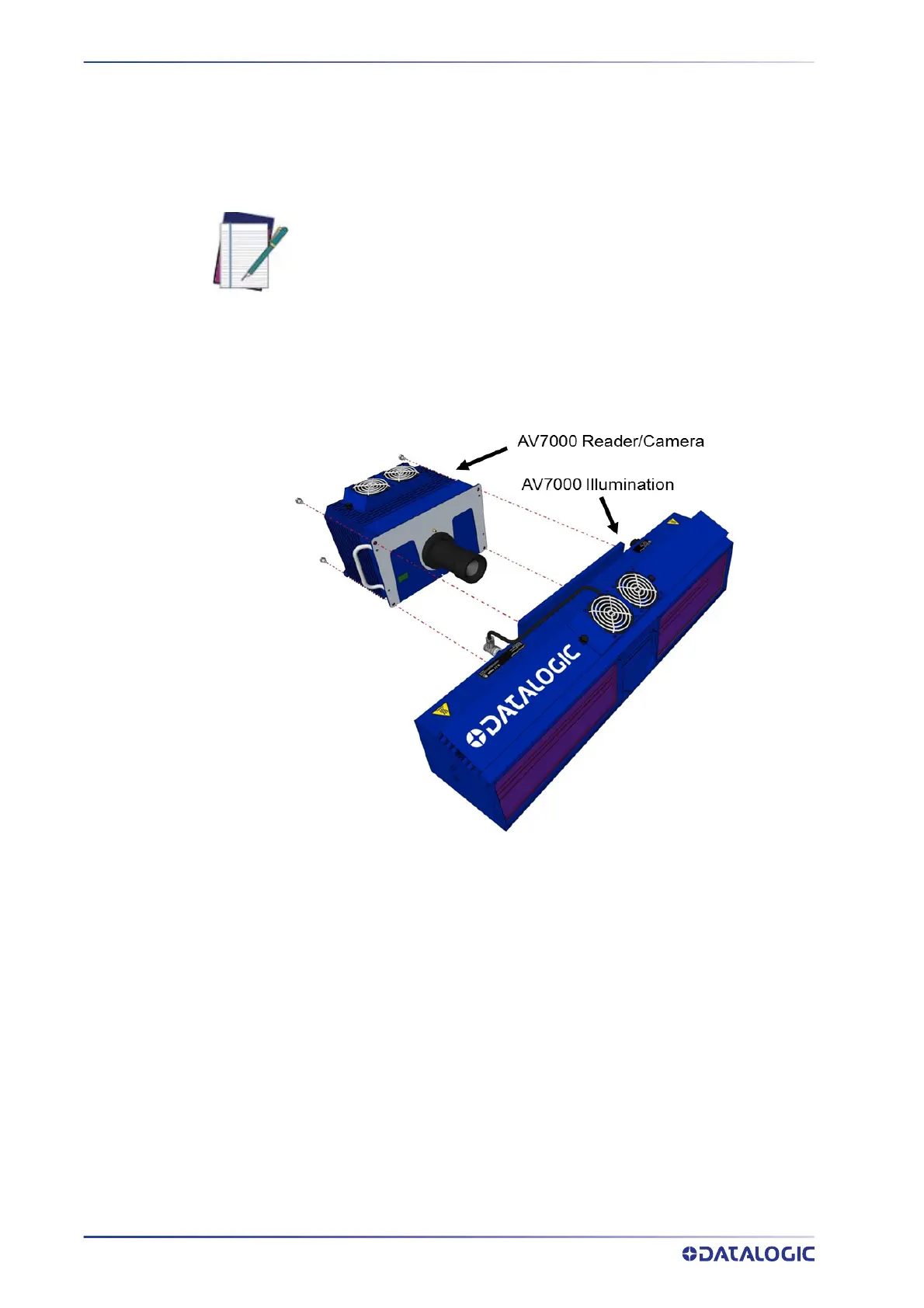

The AV7000 camera reading system consists of two pieces:

1. A barcode reader/camera for acquiring images and locating and reading the codes

on a target.

2. A lighting system for illuminating the target codes to be acquired.

Most reading system applications use a network of multiple cameras.

All linear cameras need to know the moving speed of the targets to be acquired, so the

c

onveyor speed must be constantly measured. There are several ways to accomplish

this.

•

Optical Encoder Wheel (Tachometer): Used underneath a conventional conveyor.

The encoder generates a pulse per specified distance (mm [in]) of conveyor travel.

• I

nternal Tach: This is a software-generated pulse mimicking an encoder/tachome-

ter.

•

PGD100 Speed Detector: Used with tilt-tray or cross-belt sorters. This detector

uses a series of photoelectric sensors to determine the conveyor speed.

The position sensor (DM3610, RangeFinder, ligh

t curtain (DS2), or S85 Position Sensor)

can be used as a trigger source. When the height or left/right focus data measured by

NOTE: If looking for information regarding DK501 - S80 Distance Kit, see

previous v

ersions of this product guide.

Loading...

Loading...