AUTOMATED MOUNTING CALIBRATION

230

AV7000 LINEAR CAMERA

AUTOMATED MOUNTING CALIBRATION

• “Prerequisites” on page 230

• “Package Setup” on page 230

• “Calibration” on page 232

• “Error Handling” on page 238

• “Dynamic Calibration Errors” on page 239

Prerequisites

The following requirements are necessary before performing Dynamic Calibration.

• Position Sensor(s) (if available) must be fully calibrated and enabled in

Operating

Mode.

• Minimum and maximum package sizes must be entered into

Object Detection.

• You must be able to move, transport and induct packages.

• Four printed calibration targets per package must be available.

• Two test packages must be available.

• Packages must allow the maximum amount of distance between the near and

far of each camera’s working range.

• If a Top camera is present, two packages with a height difference of at least

203 mm are required.

• If no Top camera is present, packages can be the same size.

• Cross Belts and Tilt Trays

• The trigger source must be set to Position Sensor if the camera(s) being cal-

ibrated are mounted over a cross belt or tilt tray sorter (or any application where

trigger represents a tray and not the package).

• Trigger source to position sensor distance needs to be configured manually.

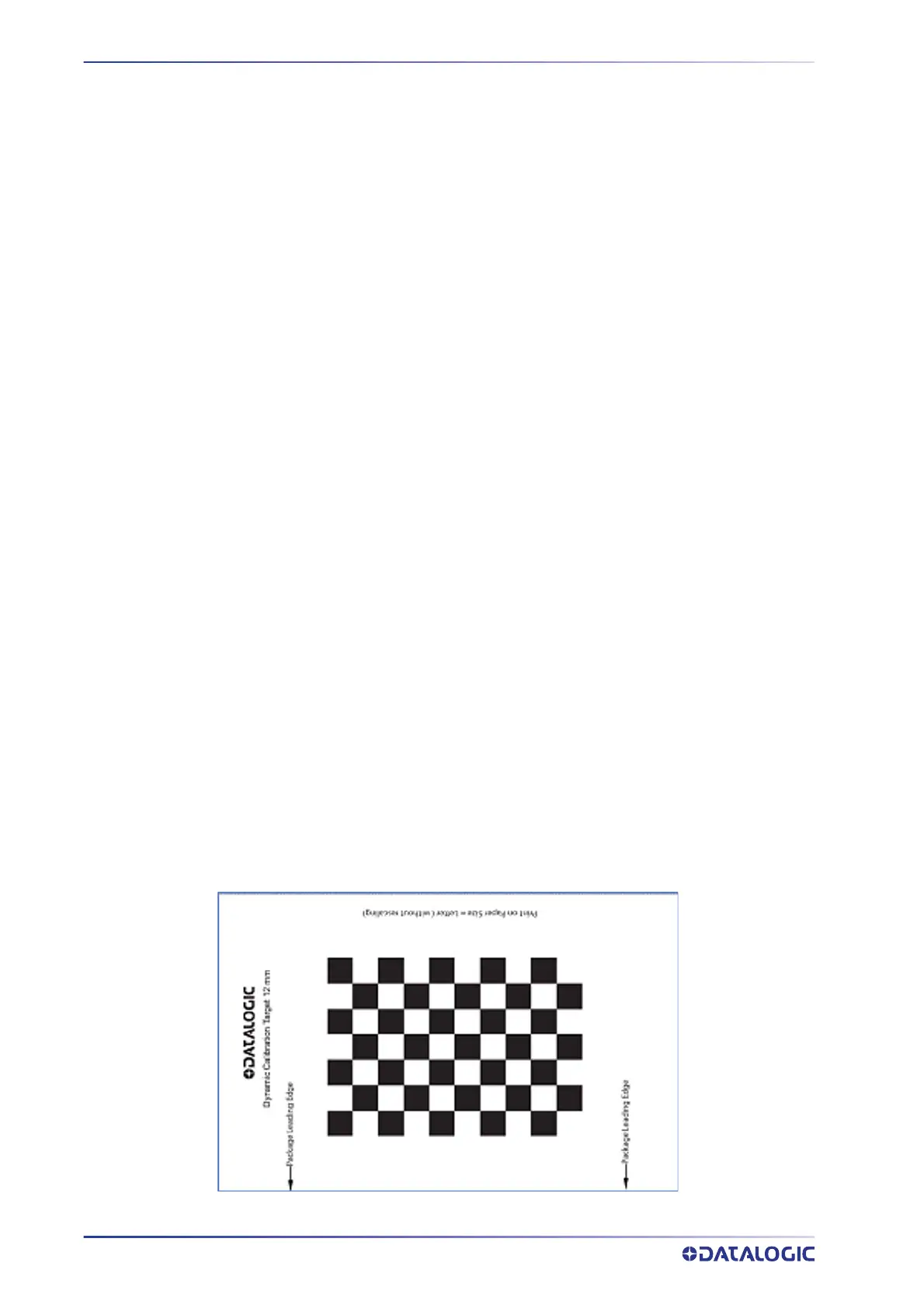

Package Setup

Place a calibration target on the top, bottom, left, and right surfaces of each package to

be used for calibration. The

Package Leading Edge arrows on the target must face the

leading edge of each package surface.

• Top target is not needed if top camera is not being calibrated

• Left and right targets are not needed if left and right side cameras are not

being calibrated

• Bottom target is not needed if a bottom camera is not being calibrated

Loading...

Loading...