214323 379 Revision A

5.8.4 Installing Knifehead Bearing

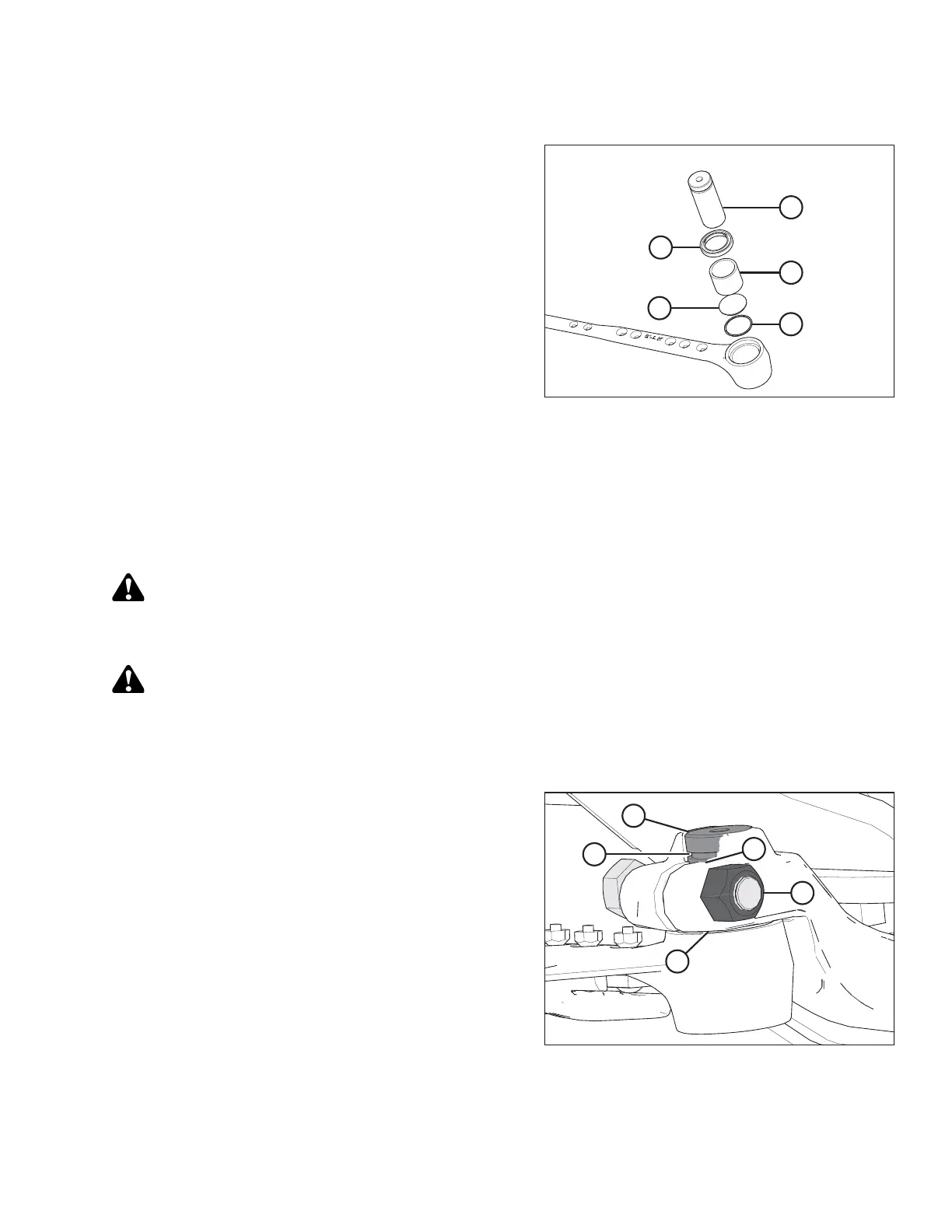

Figure 5.104: Knifehead Bearing Assembly

1. Place O-ring (E) and plug (D) into knifehead.

IMPORTANT:

Install the bearing with the stamped end (the end with

the identification markings) facing up.

2. Use a flat-ended tool with the same approximate

diameter as bearing (C), and push the bearing into the

knifehead until the top of the bearing is flush with the

step in the knifehead.

3. Install seal (B) into knifehead with the lip

facing outwards.

IMPORTANT:

To prevent premature knifehead or knife drive box

failure, ensure there’s a tight fit between knifehead pin

(A) and the needle bearing, and also between the

knifehead pin and the output arm.

4. Install the knife. Refer to 5.8.5 Installing Knife, page

379.

5.8.5 Installing Knife

WARNING

To avoid bodily injury or death from unexpected start-up or fall of raised machine, always stop engine,

remove key, and engage safety props before going under machine for any reason.

WARNING

Stand to rear of knife during installation to reduce risk of injury from cutting edges. Wear heavy gloves

when handling knife.

1. Stop engine and remove the key from ignition.

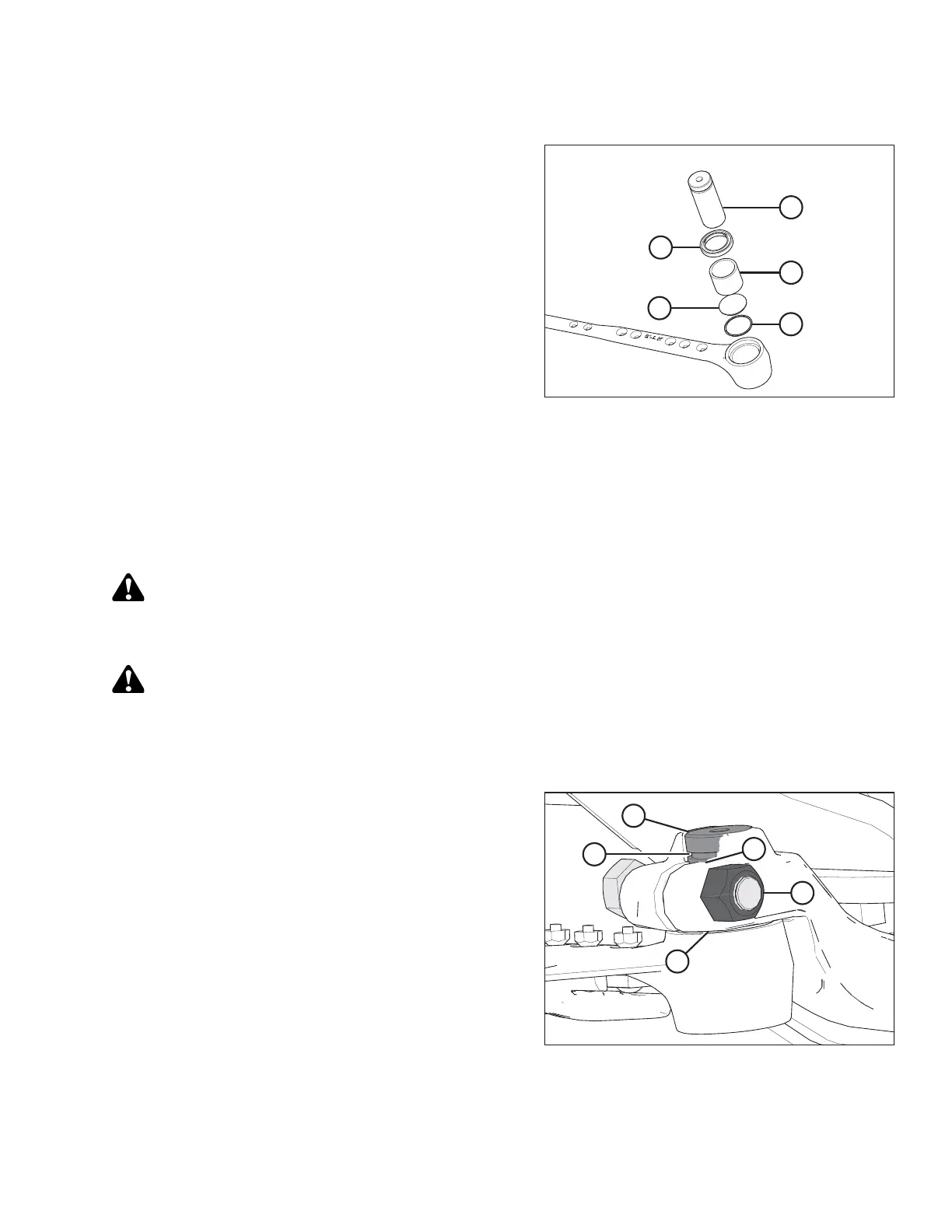

Figure 5.105: Knifehead

2. Slide the knife into place and align the knifehead with

the output arm.

3. For ease of removing or installing knifehead pin,

remove grease zerk from pin.

4. Install knifehead pin (A) through the output arm and into

the knifehead. Tap knifehead pin (A) down, make sure

the pin is seated at the bottom of the knifehead.

5. Set groove (B) in the knifehead pin 1.5 mm (1/16 in.)

above output arm (C). Secure with 5/8 in. x 3 in. hex

head bolt and nut (D), and torque to 217 Nm (160 lbf·ft).

6. Using a feeler gauge, check that the gap at location (E)

is 0.25 mm (0.01 in.).

MAINTENANCE AND SERVICING

Loading...

Loading...