214323 21 Revision A

2.2 Specifications

The following symbol and letters are used in Table 2.1, page 21 and Table 2.2, page 23:

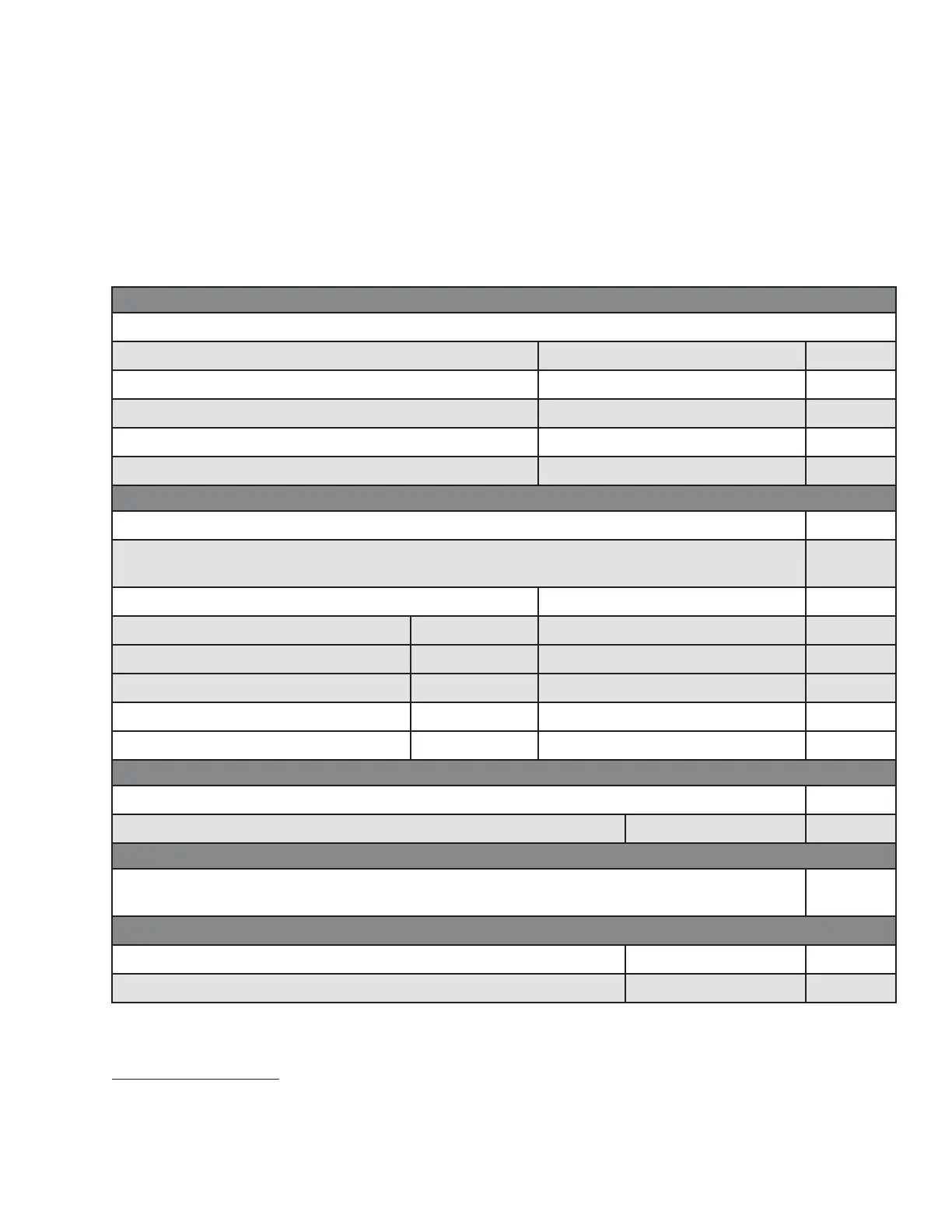

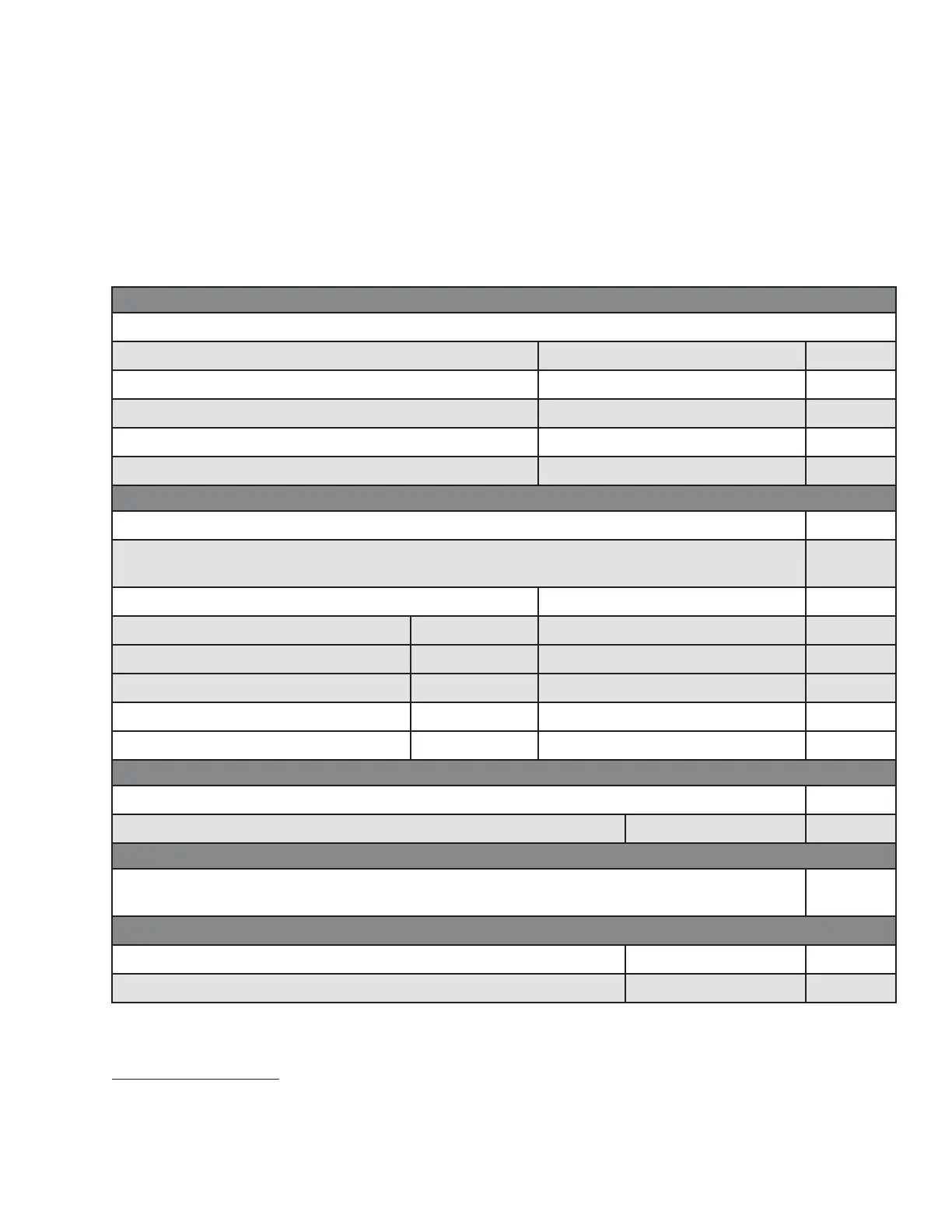

| FD75 | CA25 | Attachments

S: standard / O

F

: optional (factory installed) / O

D

: optional (dealer installed) / -: not available

Table 2.1 Header Specifications

Cutterbar

Effective cutting width (distance between crop divider points)

9.1 m (30-ft.) header 9144 mm (360 in.) S

10.6 m (35-ft.) header 10668 mm (420 in.) S

12.2 m (40-ft.) header 12192 mm (480 in.) S

13.7 m (45-ft.) header 13716 mm [540 in.) S

Cutterbar lift range

Varies with combine model

S

Knife

Single-knife drive (all sizes): one hydraulic motor with V-belt to one heavy duty knife drive box.

O

F

Double-knife drive (40-, 45-foot only, non-timed): two hydraulic motors with banded-belts to two

heavy duty knife drive boxes.

O

F

Knife stroke 76 mm (3 in.) S

Single-knife speed (strokes per minute)

1

9.1 m (30 ft.)

1200–1400 spm

S

Single-knife speed (strokes per minute)

1

10.6 m (35 ft.)

1100–1300 spm

S

Single-knife speed (strokes per minute)

1

12.2 m (40 ft.)

1050–1200 spm

S

Double-knife speed (strokes per minute)

1

12.2 m (40 ft.) 1100–1400 spm S

Double-knife speed (strokes per minute)

1

13.7 m (45 ft.)

1100–1400 spm

S

Knife Sections

Over-serrated / solid / bolted / 9 serrations per inch S

Knife overlap at center (double-knife headers) 3 mm (0.1 in.) S

Guards and Hold-Downs

Guard: pointed / forged / double heat treated (DHT)

Hold-down: sheet metal / adjustment bolt

S

Guard Angle (Cutterbar on Ground)

Center-link retracted

2.0 degrees

S

Center-link extended

7.4 degrees

S

PRODUCT OVERVIEW

1. Under normal cutting conditions, knife speed taken at the knife drive pulley should be set between 600 and

640 rpm (1200 and 1280 spm). If set to low side of chart, you could experience knife stalling.

Loading...

Loading...