214323 399 Revision A

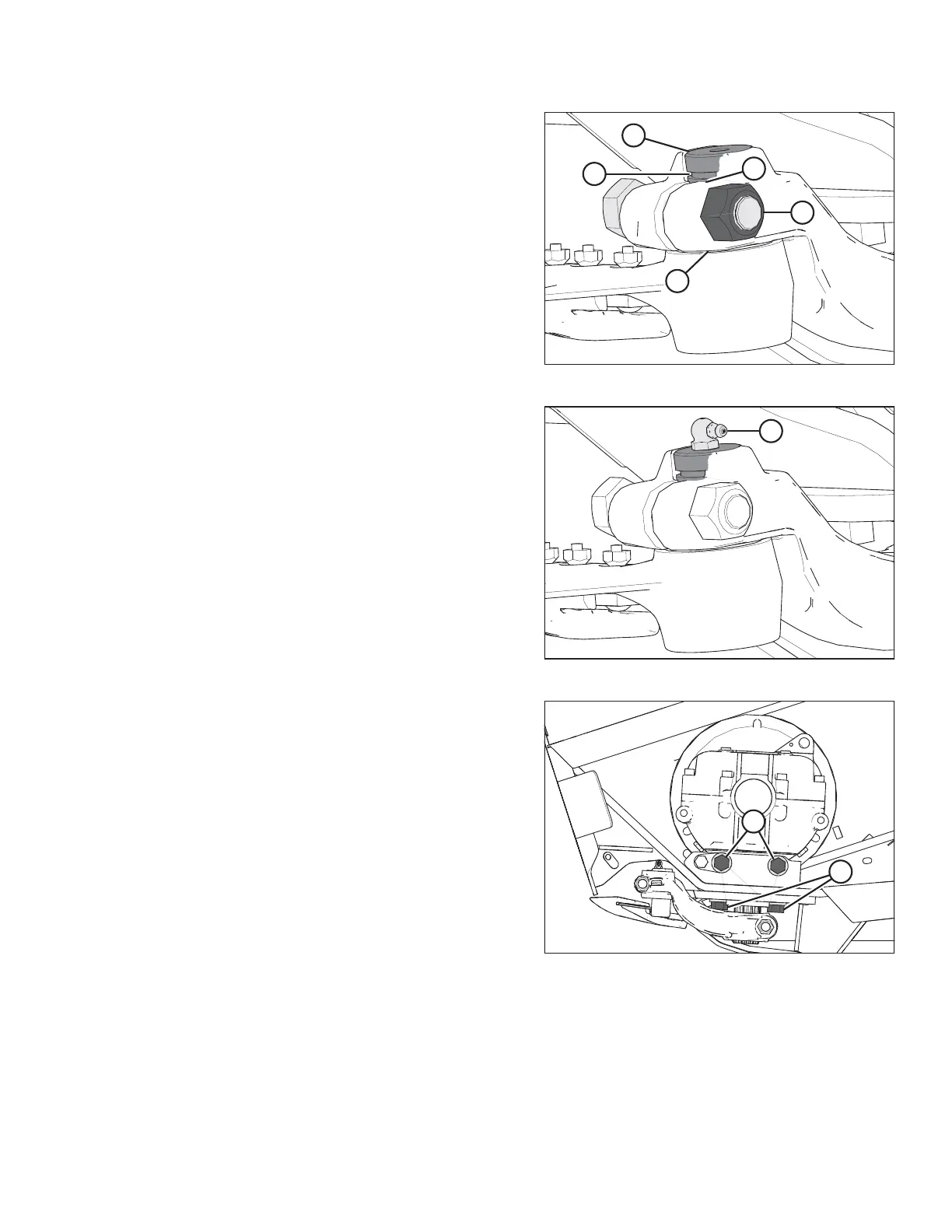

Figure 5.142: Knifehead

8. Slide the knife into place and align the knifehead with

the output arm.

9. For ease of removing or installing knifehead pin,

remove grease zerk from pin.

10. Install knifehead pin (A) through the output arm and into

the knifehead. Tap knifehead pin (A) down, make sure

the pin is seated at the bottom of the knifehead.

11. Using a feeler gauge, check that the gap at location (E)

is 0.25 mm (0.01 in.).

12. Set groove (B) in the knifehead pin 1.5 mm (1/16 in.)

above output arm (C). Secure with 5/8 in. x 3 in. hex

head bolt and nut (D), and torque to 217 Nm (160 lbf·ft).

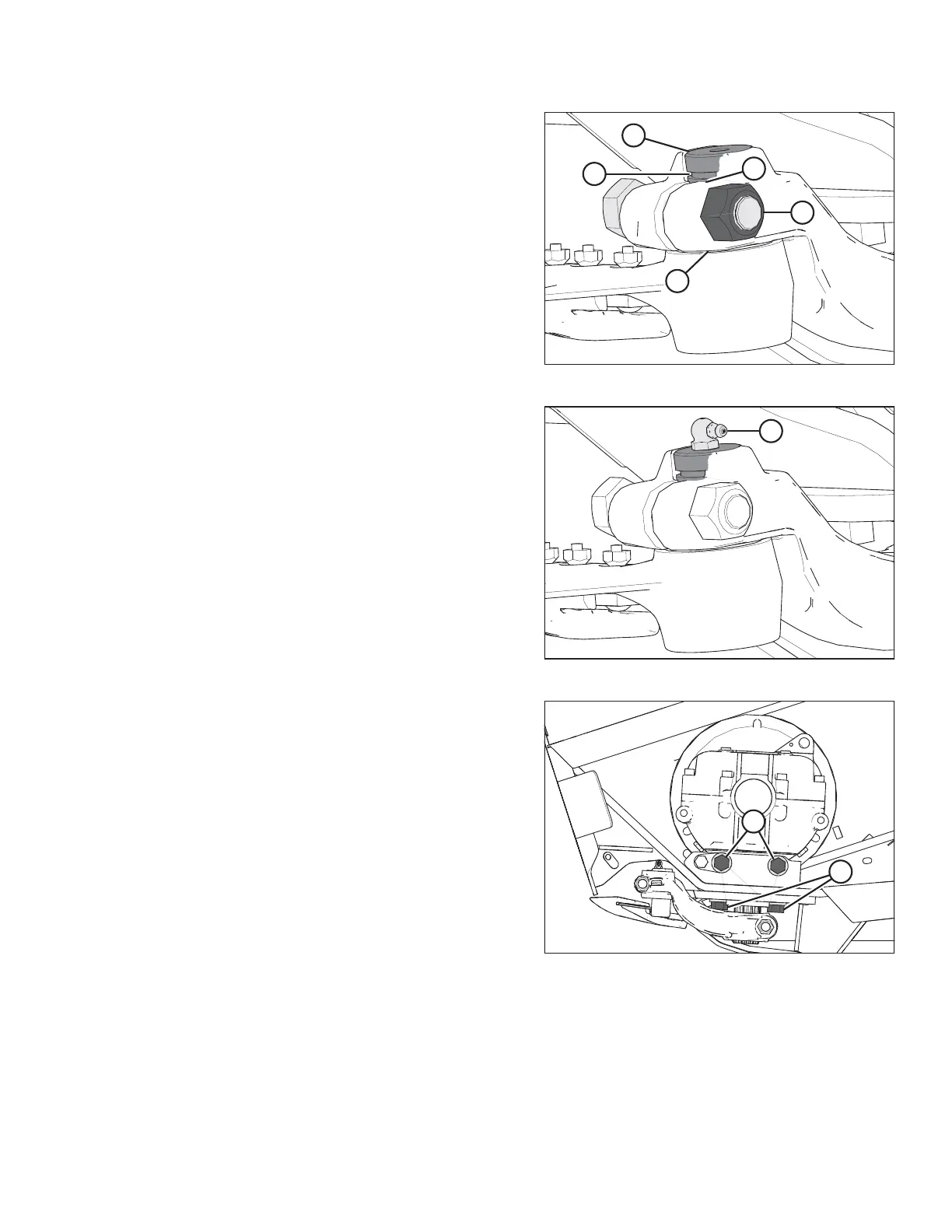

Figure 5.143: Knifehead

13. Install grease zerk (A) into the knifehead pin, and turn

the grease zerk for easy access.

IMPORTANT:

Grease knifehead just enough to start a slight

downward movement. Overgreasing will lead to knife

misalignment which causes guards to overheat and

drive systems to overload.

Figure 5.144: Knife Drive Box

14. Tighten knife drive box side bolts (A) first, then tighten

the bottom bolts (B). Torque to 271 Nm (200 lbf·ft).

15. Move the output arm to the midstroke position, and

ensure the knife bar doesn’t contact the front of the first

guard. If the knife drive box requires adjustment,

contact your MacDon Dealer.

16. Install and tension the knife drive belts. Refer to

Tensioning Knife Drive Belts, page 402

17. Close the endshield. Refer to Closing Endshield, page

32.

MAINTENANCE AND SERVICING

Loading...

Loading...