214323 403 Revision A

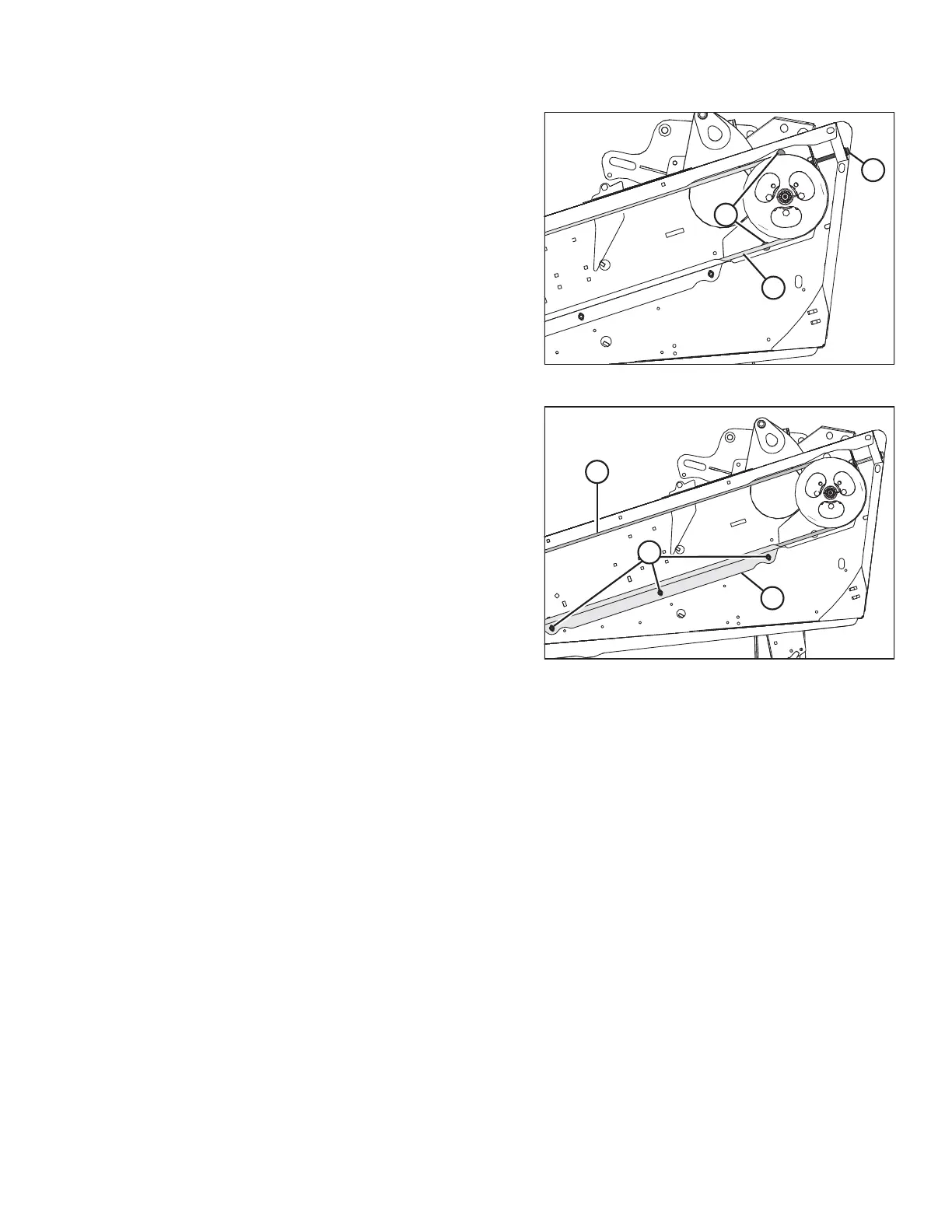

Figure 5.151: Non-Timed Knife Drive

1. Shut down machine, and remove key from the ignition.

2. Open the endshield.

3. Loosen the two bolts (A) securing the motor assembly

to the header endsheet.

4. Turn adjuster bolt (B) clockwise to move drive motor

until a force of 89 N (20 lbf) deflects belt (C) 20 –25 mm

(3/4–1 in.) at midspan.

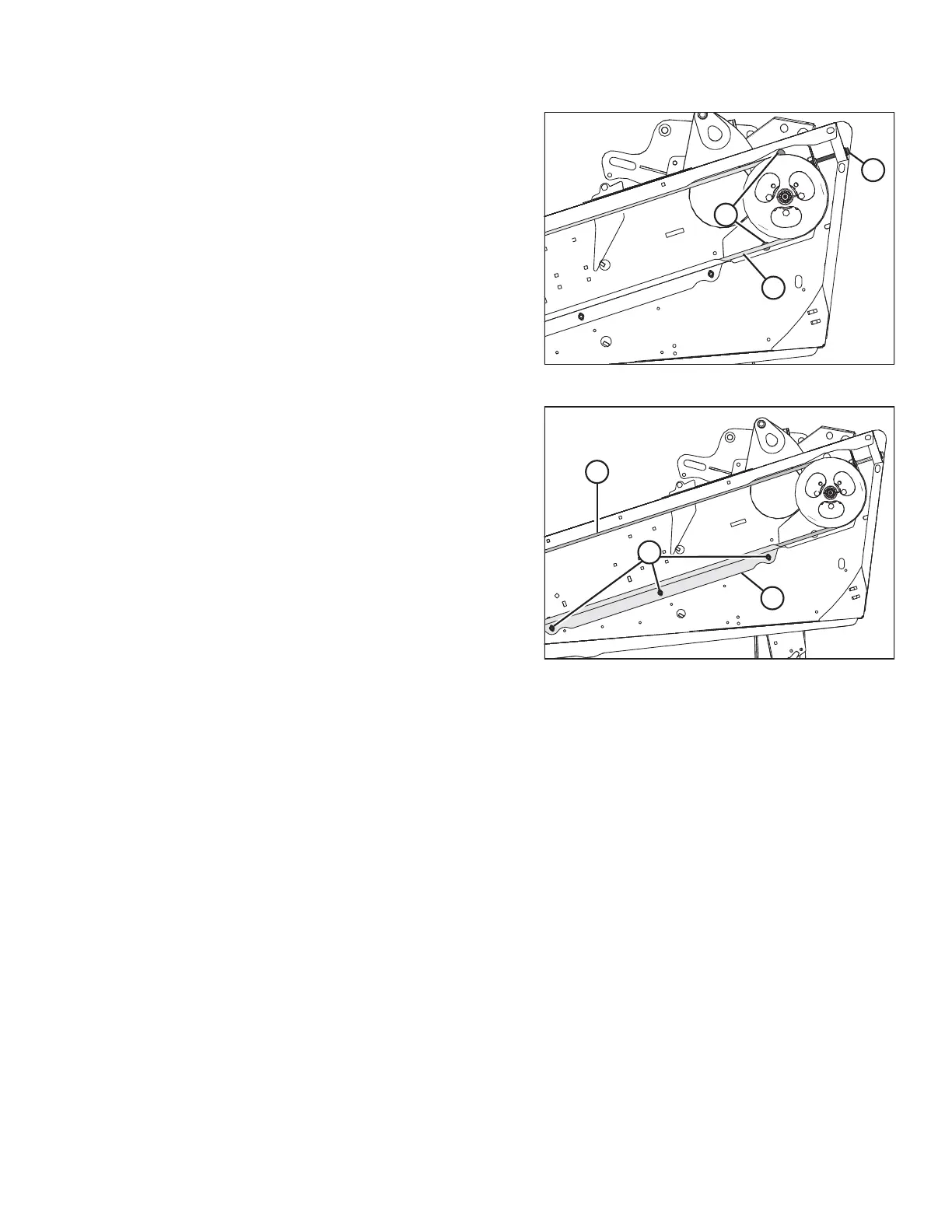

Figure 5.152: Non-Timed Knife Drive

5. Ensure clearance between belt (A) and belt guide (B) is

1 mm (1/32 in.).

6. Loosen three bolts (C), and adjust position of guide (B)

as required.

7. Tighten three bolts (C).

8. Close endshield. Refer to Closing Endshield, page 32.

NOTE:

Readjust tension of a new belt after a short run-in

period (about five hours).

9. Repeat above steps for opposite end on double-knife

headers.

MAINTENANCE AND SERVICING

Loading...

Loading...