214323 54 Revision A

Adjusting Stabilizer/Slow Speed Transport Wheels

A properly adjusted header will achieve a balance between the amount of header weight carried by the float and

the amount carried by the stabilizer/slow speed transport wheels.

Refer to 3.6.2 Header Settings, page 42 for recommended use in specific crops and crop conditions.

DANGER

To avoid bodily injury or death from unexpected start-up of machine, always stop engine and remove key

from ignition before leaving operator’s seat for any reason.

1. Raise the header so the stabilizer wheels are off the ground. Shut down engine and remove key.

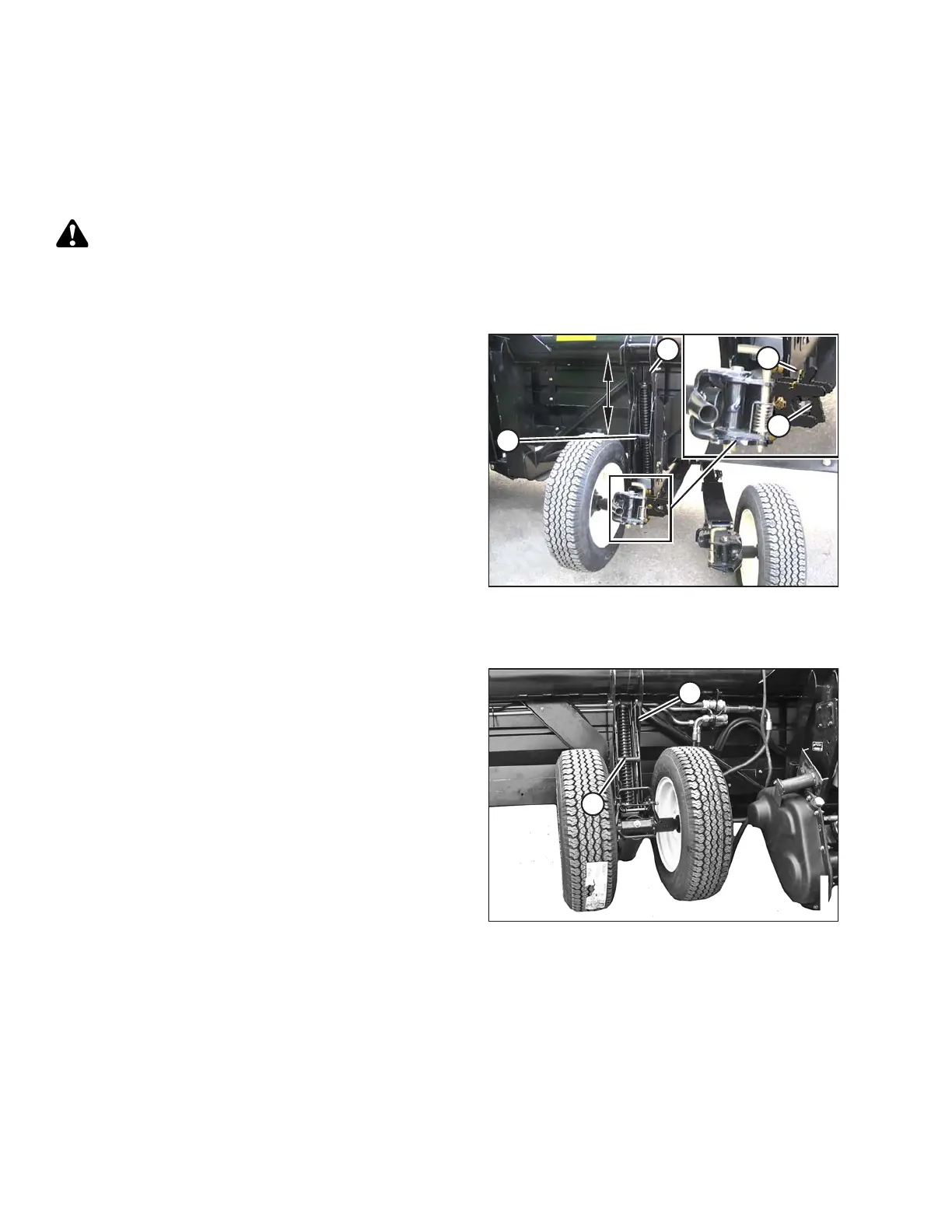

Figure 3.24: Right Wheel

2. Remove hairpin (A) from the latch on the right wheel

assembly.

3. Disengage latch (B), lift the wheel out of the hook, and

place wheel on the ground as shown. (This reduces

weight of assembly and makes adjusting the wheel

position easier.)

4. Lift the left wheel slightly to support weight, and pull

handle (C) upwards to release the lock.

5. Lift the left wheel to the desired height and engage the

support channel in slot (D) in the upper support.

6. Push down on handle (C) to lock.

7. Lift the right wheel back into the field position and

ensure latch (B) is engaged.

8. Secure the latch with hairpin (A).

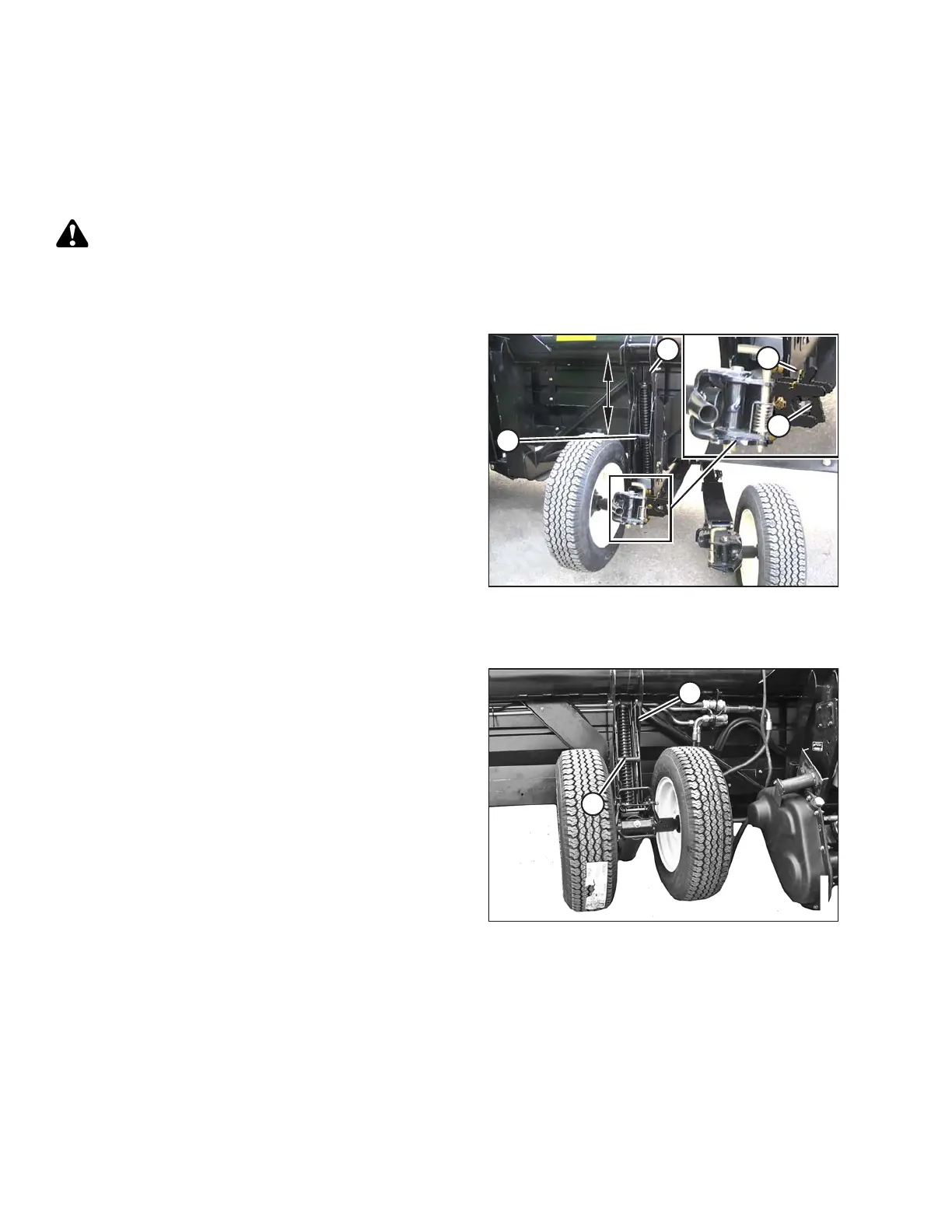

Figure 3.25: Left Wheel

9. Support the wheel weight by lifting slightly with one

hand, and pull up on handle (A) to release the lock.

10. Lift the wheels to the desired height, and engage the

support channel into slot (B) in the upper support.

11. Push down on handle (A) to lock.

OPERATION

Loading...

Loading...