215916 213 Revision A

14. If necessary, calibrate both the knife drive and header position sensors on the windrower. Calibrate both the knife

drive and header position sensors whenever you are:

• Attaching the header to the windrower for the first time

• Changing the speed sensor or hydraulic drive motor on the header

• Changing the header drive pump associated with the knife drive, Harvest Performance Tracker (HPT), or the master

controller on the windrower

For instructions, refer to .

Connecting R2 Series Rotary Disc Header Hydraulics and Electrical to Windrower

The procedure for connecting the R216’s hydraulic and electrical systems to the windrower differs depending on the

configuration of the windrower.

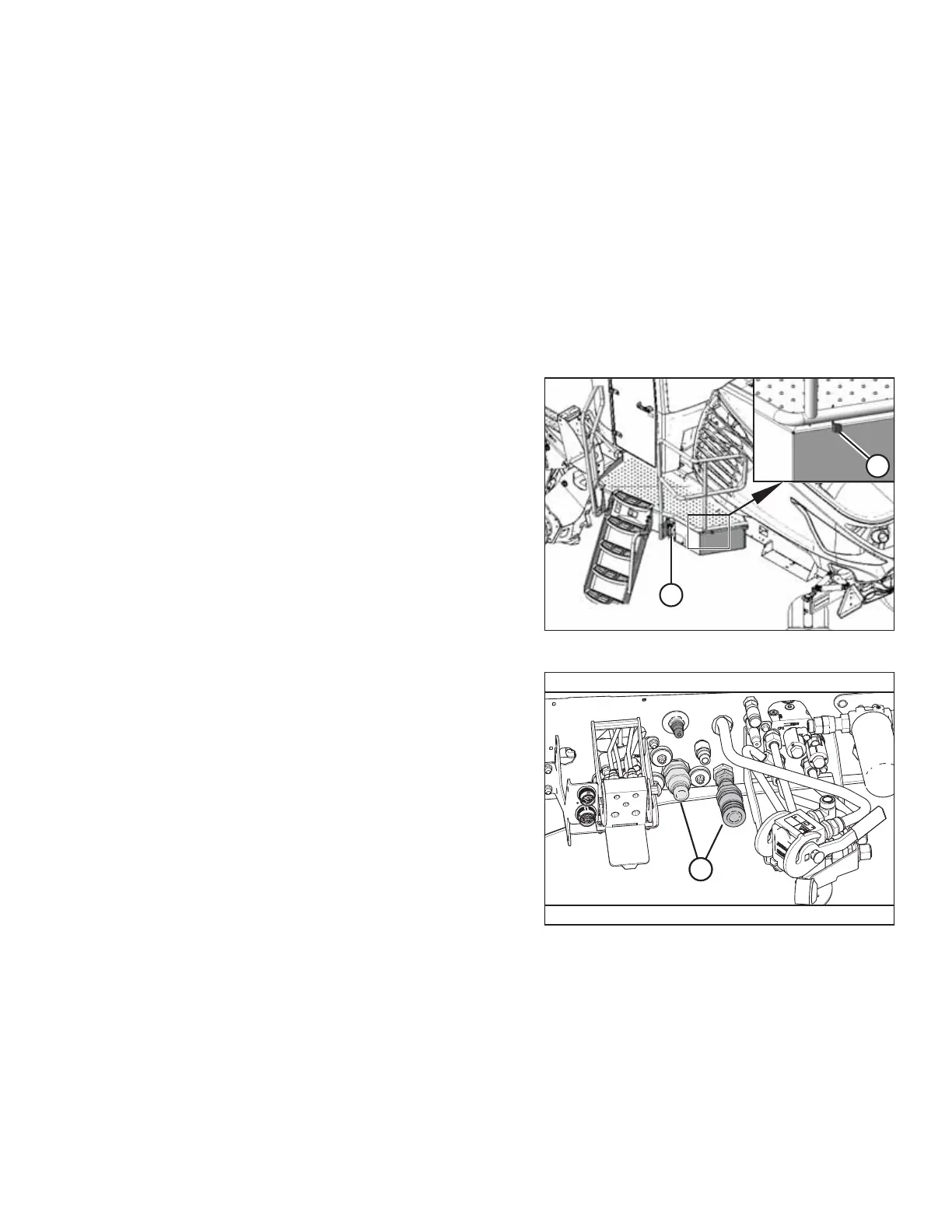

Figure 4.229: Left Cab-Forward Platform

1. Approach platform (A) on the left cab-forward side of the

windrower and ensure the cab door is closed.

2. Push latch (B), and pull platform (A) toward the walking

beam until it stops and the latch engages.

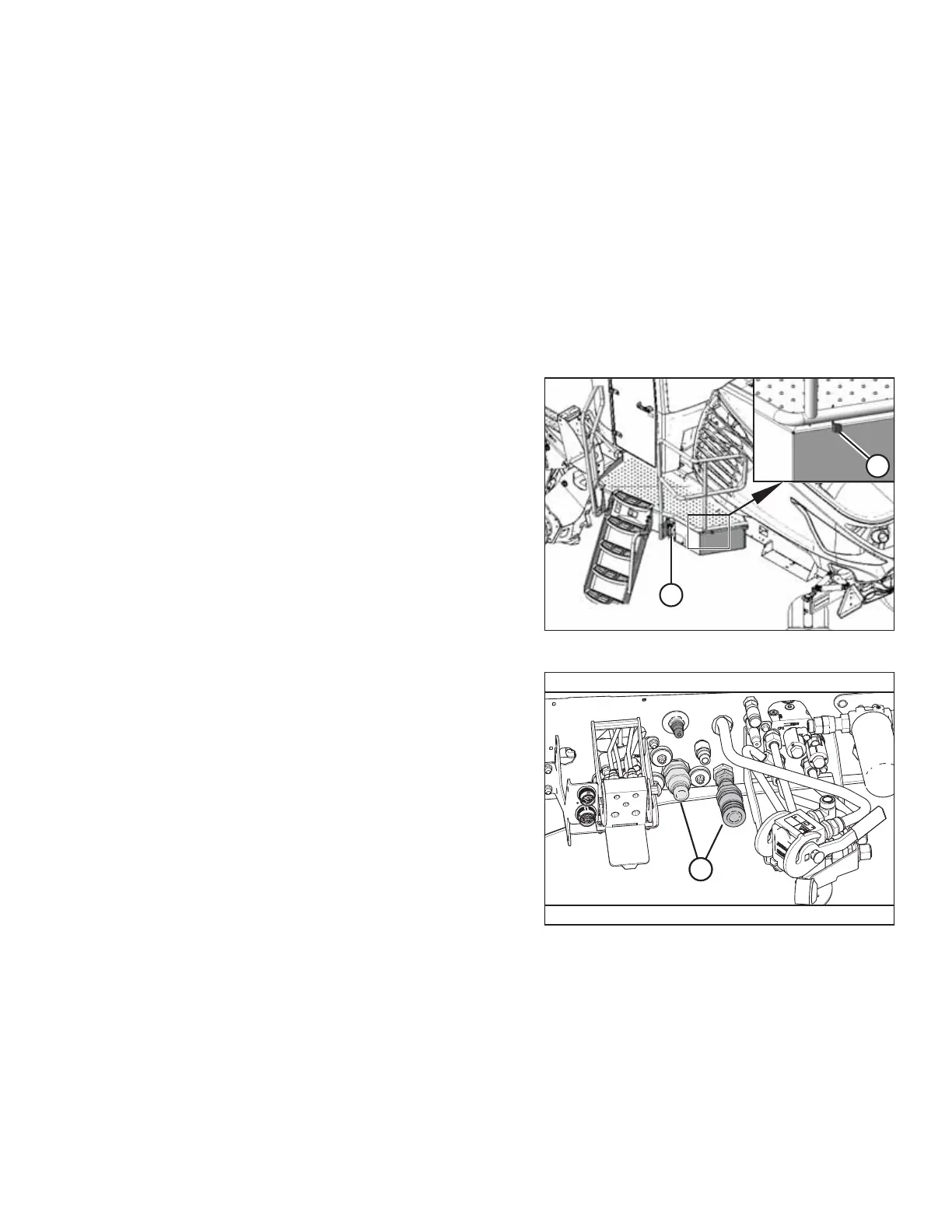

Figure 4.230: Header Hydraulics Configurations –

Auger/Rotary Disc/Draper-Ready

Proceed with the steps relevant to your windrower

configuration:

• Auger/rotary disc/draper-ready configuration (A): For

instructions, refer to Auger/Rotary Disc/Draper-Ready

Configuration – Quick Coupler Connections, page 214.

OPERATION

Loading...

Loading...