215916 402 Revision A

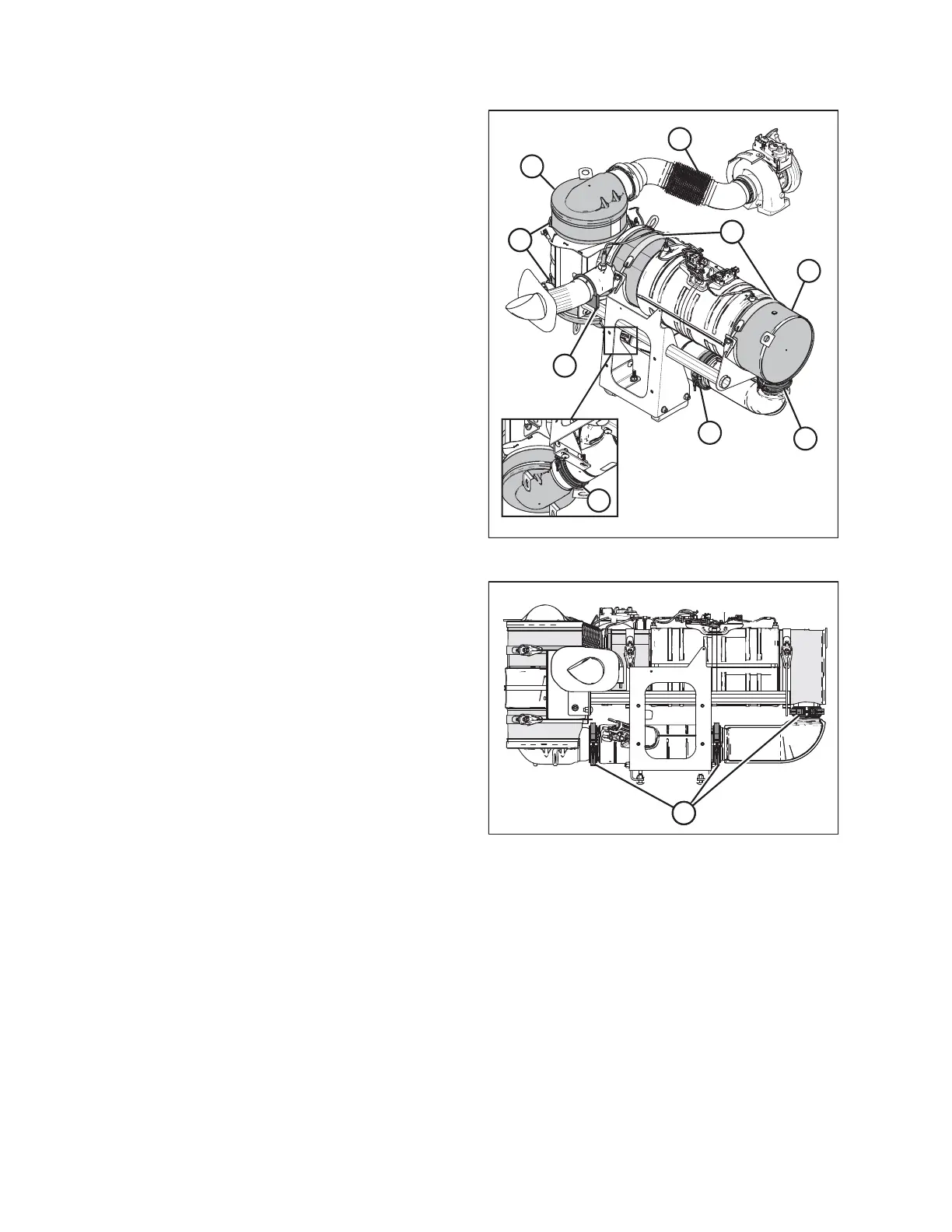

Figure 5.107: Exhaust System

2. Check the following:

a. Exhaust canisters (A) and bellow tube (B) for dents,

cracks, and wear.

b. Straps (C) for tightness.

c. U-bolt (D) and band clamps (E) for breakage, cracks,

and rust.

IMPORTANT:

Damaged exhaust piping, clamps, or components can

lead to exhaust leaks and engine derate.

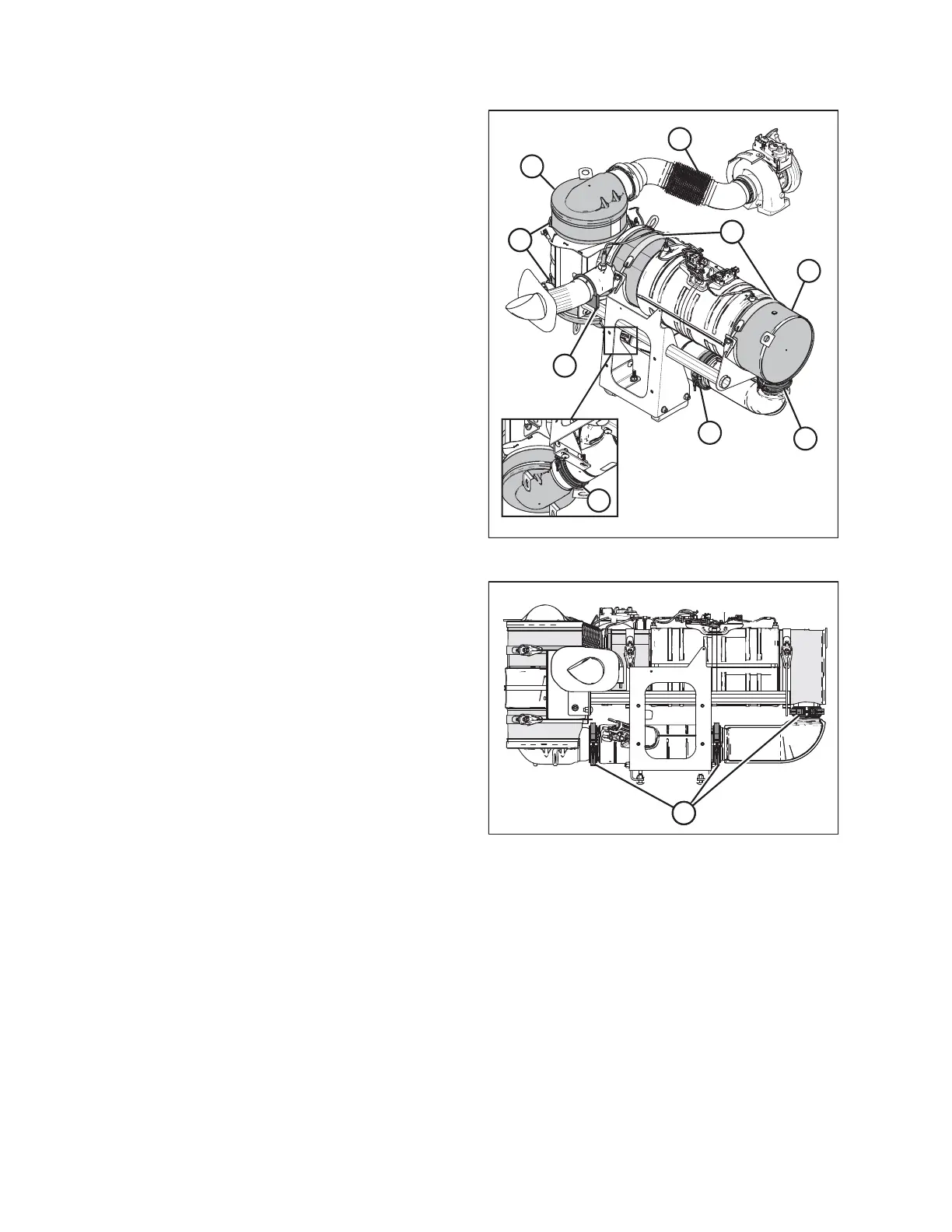

Figure 5.108: Exhaust Canister

3. Check the three band clamps (A) securing the tubes in

between the two exhaust canisters.

IMPORTANT:

Do NOT change exhaust canister type, piping sizes, or

exhaust configuration. Contact your Dealer for proper

replacement parts.

4. Inspect the area around clamps (A) for breakage, cracks,

and rust-through.

IMPORTANT:

If exhaust is leaking, tighten clamps to 12–15 Nm

(9–11 lbf·ft). If it is leaking at the band connection, replace

the seals. Contact your Dealer if exhaust leak persists.

5. Check the tubing for dents or crushed areas.

IMPORTANT:

Dents or crushed portions of any tubing create exhaust flow

restriction and increase back pressure significantly. Even

relatively small dents will cause decreased fuel economy

and increased turbo wear. If dents are relatively large,

increased bearing and cylinder wear will occur due to

increased exhaust temperature.

MAINTENANCE AND SERVICING

Loading...

Loading...