215916 505 Revision A

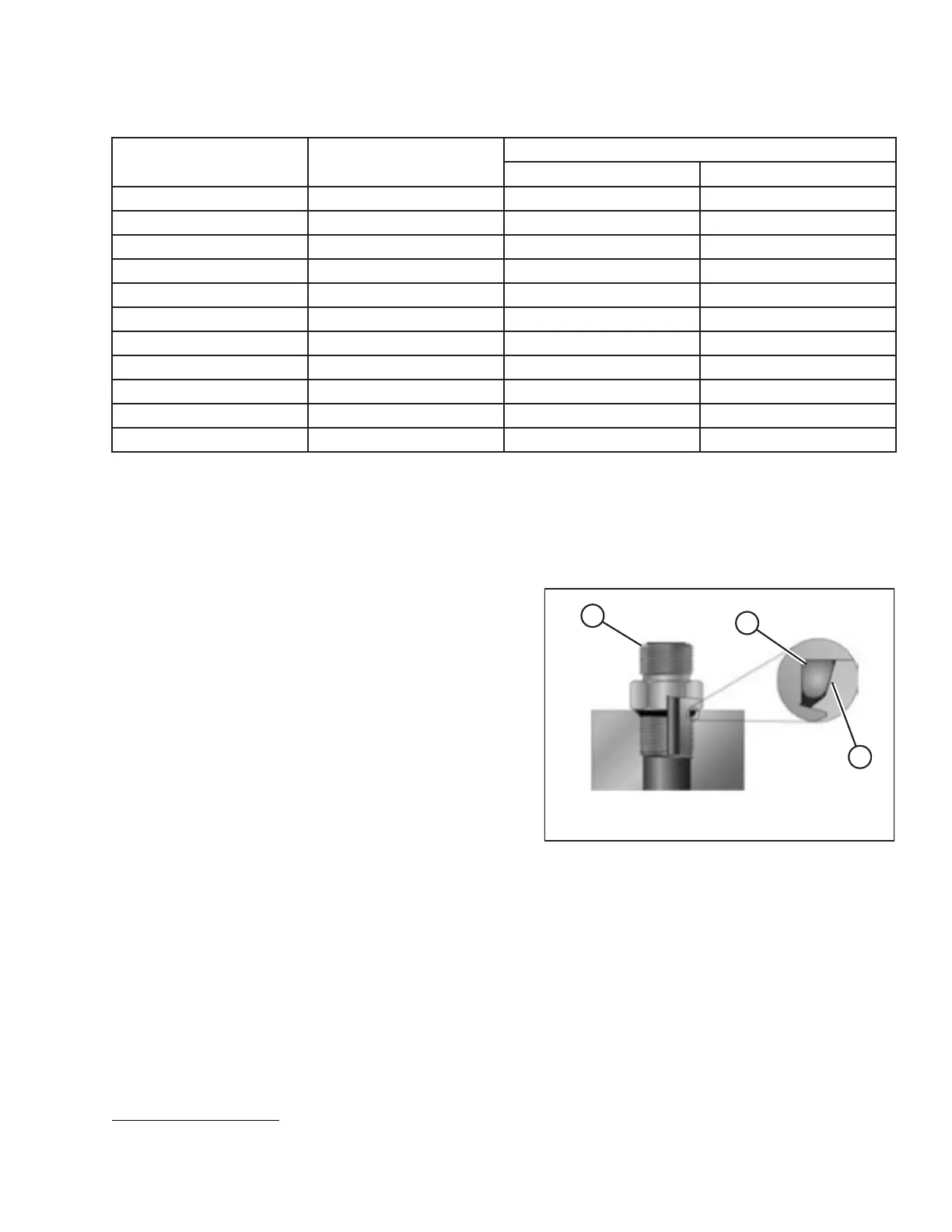

Table 8.6 O-Ring Boss (ORB) Hydraulic Fittings – Adjustable (continued)

SAE Dash Size

Thread Size (in.)

Torque Value

31

Nm

lbf·ft (*lbf·in)

-4

7/16–20

19–21 14–15

-5

1/2–20

21–33 15–24

-6

9/16–18

26–29 19–21

-8

3/4–16

46–50 34–37

-10

7/8–14

75–82 55–60

-12

1 1/16–12

120–132 88–97

-14

1 3/8–12

153–168 113–124

-16

1 5/16–12

176–193 130–142

-20

1 5/8–12

221–243 163–179

-24

1 7/8–12

270–298 199–220

-32

2 1/2–12

332–365 245–269

8.1.4 O-Ring Boss Hydraulic Fittings – Non-Adjustable

The standard torque values are provided for non-adjustable hydraulic fittings. If a procedure specifies a different torque

value for the same type and size of fitting found in this topic, use the value specified in the procedure instead.

Torque values are shown in the table below.

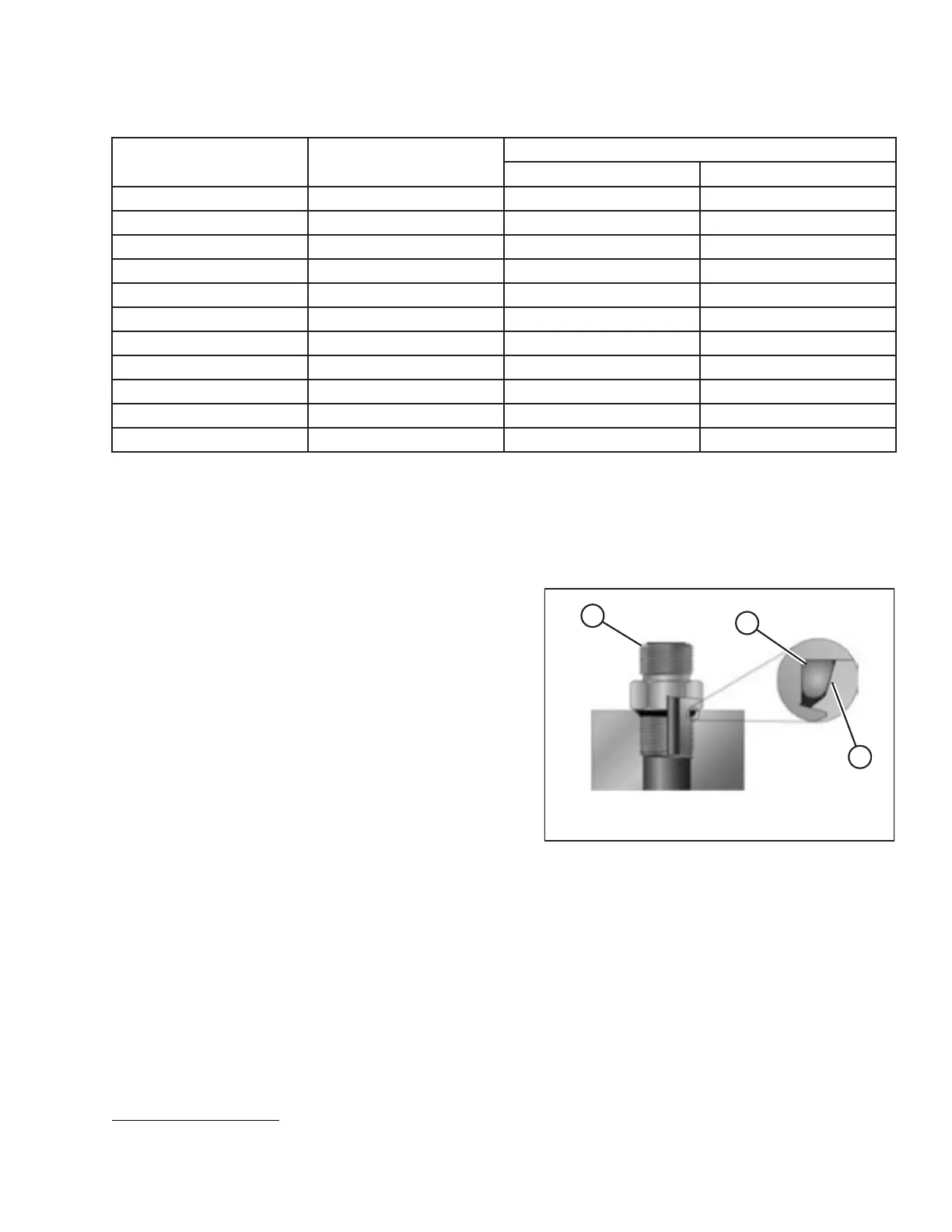

Figure 8.8: Hydraulic Fitting

1. Inspect O-ring (A) and seat (B) for dirt or obvious defects.

2. Check that O-ring (A) is NOT on the threads. Adjust O-

ring (A) if necessary.

3. Apply hydraulic system oil to the O-ring.

4. Install fitting (C) into the port until the fitting is hand-tight.

5. Torque fitting (C) according to values in Table 8.7, page

506.

6. Check the final condition of the fitting.

REFERENCE

31. Torque values shown are based on lubricated connections as in reassembly.

Loading...

Loading...