M1: Kinematic transformation

6.4 TRAANG oblique angle transformation (option)

Extended Functions

378 Function Manual, 03/2013, 6FC5397-1BP40-3BA1

Interrupt part program

● Mode change from AUTOMATIC to JOG

If a part program machining is interrupted for active transformation and traversed

manually in the JOG operating mode, ensure for continuation of the part program in the

AUTOMATIC operating mode that the transformation is already active in the restart block

from the current position to the interruption location.

WARNING

Risk of collision

No monitoring for collisions takes place.

The operator is responsible for ensuring that the tool can be re-positioned without any

difficulties.

● START after RESET

If a part program machining is interrupted with

RESET and restarted with START, ensure that

at part program begin all axes travel with a linear block (G0 or G1) to a defined position,

and the remaining part program is traversed reproducably. A tool which was active on

RESET may no longer be taken into account by the control (settable via machine data).

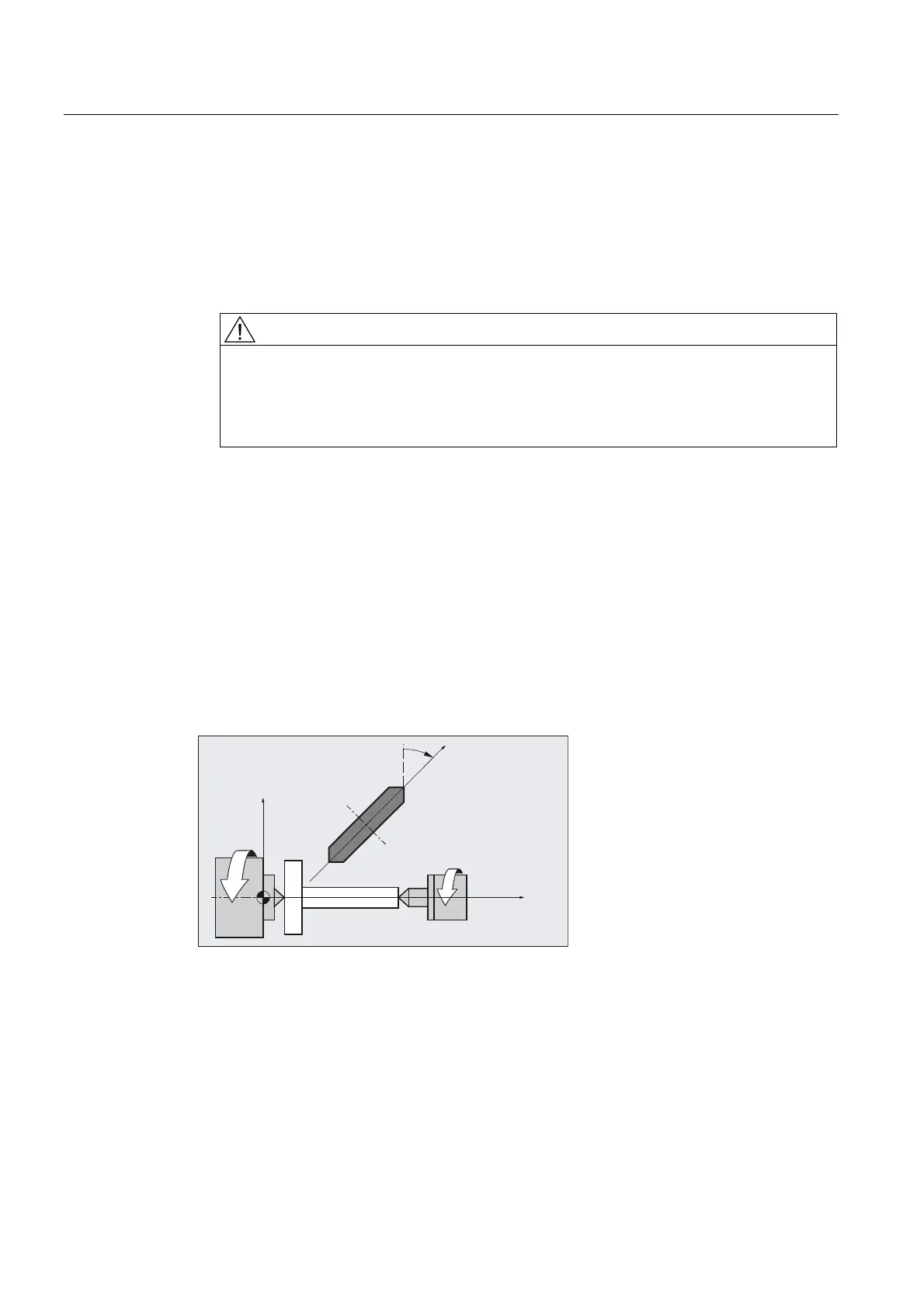

6.4 TRAANG oblique angle transformation (option)

The angle transformation or "inclined axis" transformation permits the programming in the

perpendicular workpiece coordinate system (WCS) on machines with inclined machine axes.

A typical axis orientation for grinding machines:

=0=

$6

&

˞

08

;

*ULQGLQJGLVN

:RUNSLHFH

X Geometry axis

Z Geometry axis

MZ Machine axis

MU Machine axis

α Angle of inclined axis

Loading...

Loading...