Z2: NC/PLC interface signals

18.17 Grinding-specific tool offset and tool monitoring (W4)

Extended Functions

908 Function Manual, 03/2013, 6FC5397-1BP40-3BA1

18.17 Grinding-specific tool offset and tool monitoring (W4)

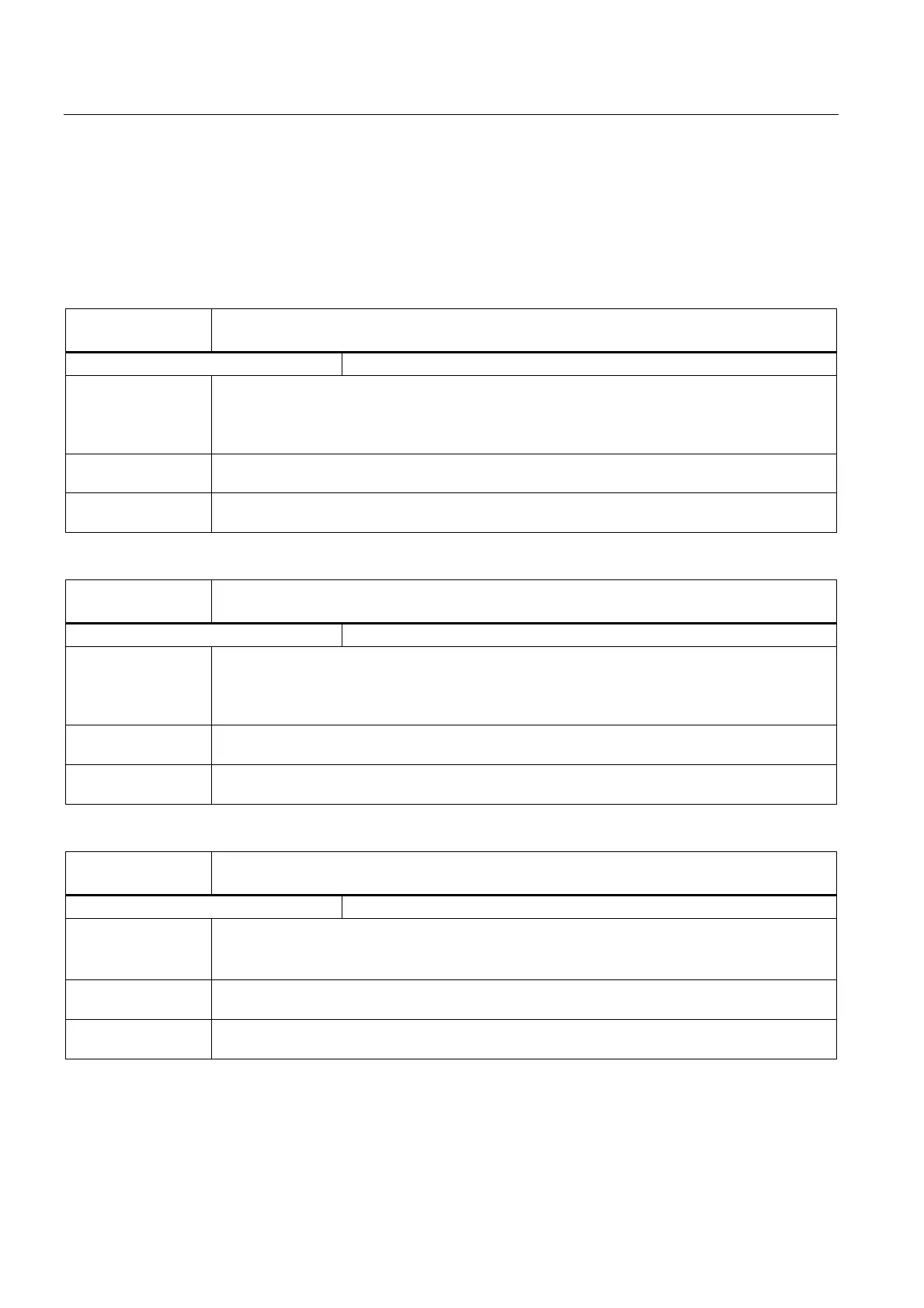

18.17.1 Signals from axis/spindle (DB31, ...)

DB31, ...

DBX83.3

Geometry monitoring

Edge evaluation: No Signal(s) updated: -

Signal state 1 or

edge change 0 → 1

Error in grinding wheel geometry.

Note:

There is no further reaction to the response of this monitoring function.

Reactions deemed necessary must be programmed by the PLC user.

Signal state 0 or

edge change 1 → 0

No error in grinding wheel geometry.

Application

example(s)

Grinding-specific tool monitoring

DB31, ...

DBX83.6

Speed monitoring

Edge evaluation: No Signal(s) updated: -

Signal state 1 or

edge change 0 → 1

Error in grinding wheel speed.

Note:

No further reaction to this signal state is programmed.

Reactions deemed necessary must be programmed by the PLC user.

Signal state 0 or

edge change 1 → 0

No error in grinding wheel speed.

Application

example(s)

Grinding-specific tool monitoring

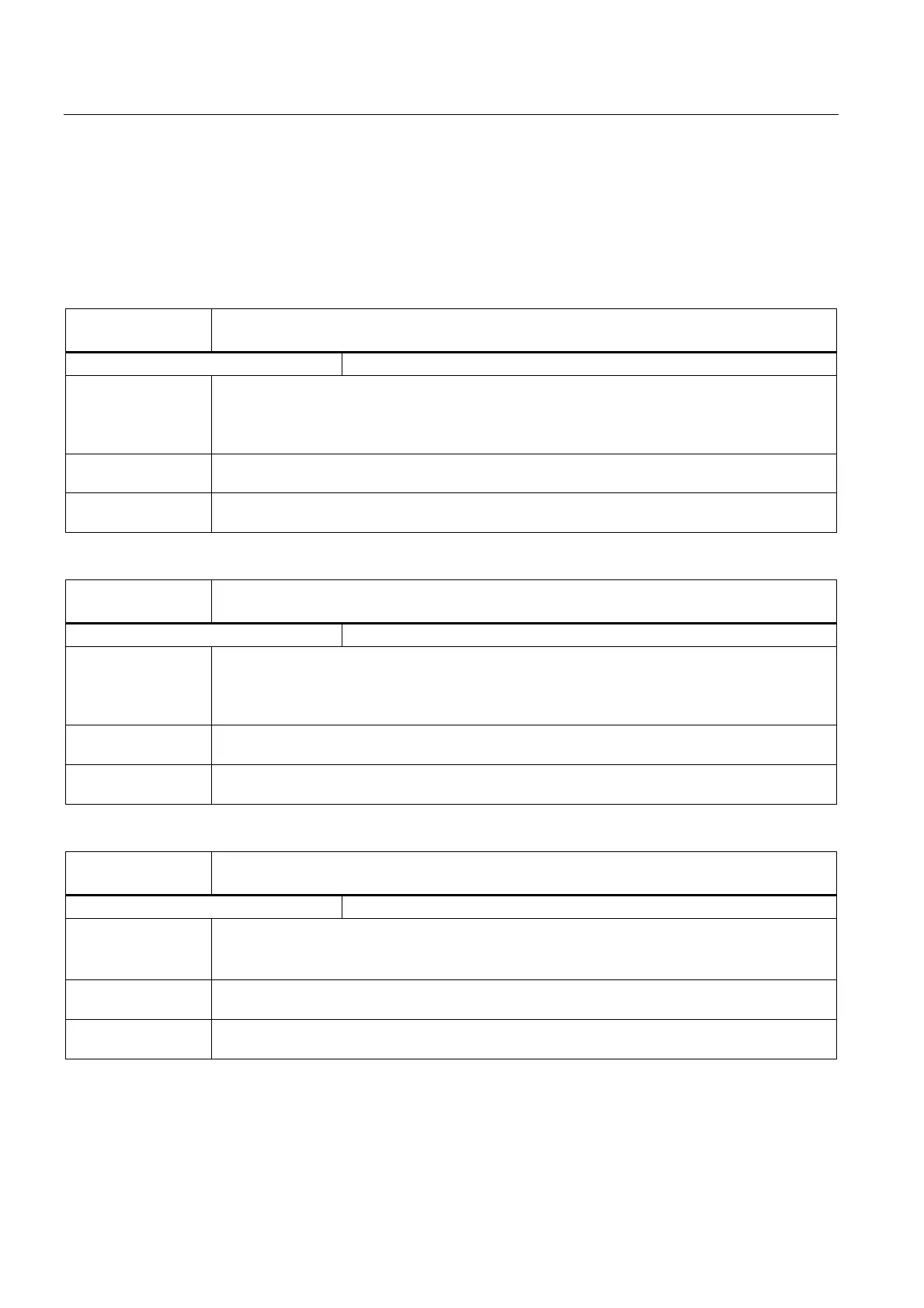

DB31, ...

DBX84.1

GWPS active

Edge evaluation: No Signal(s) updated: -

Signal state 1 or

edge change 0 → 1

Constant grinding wheel peripheral speed (GWPS) is active.

If GWPS is active, then all S value inputs from the PLC are interpreted as the grinding wheel

peripheral speed.

Signal state 0 or

edge change 1 → 0

Constant grinding wheel peripheral speed (GWPS) is not active.

Application

example(s)

GWPS in all operating modes.

Loading...

Loading...