M5: Measurement

7.5 Setting zeros, workpiece measuring and tool measuring

Extended Functions

Function Manual, 03/2013, 6FC5397-1BP40-3BA1

461

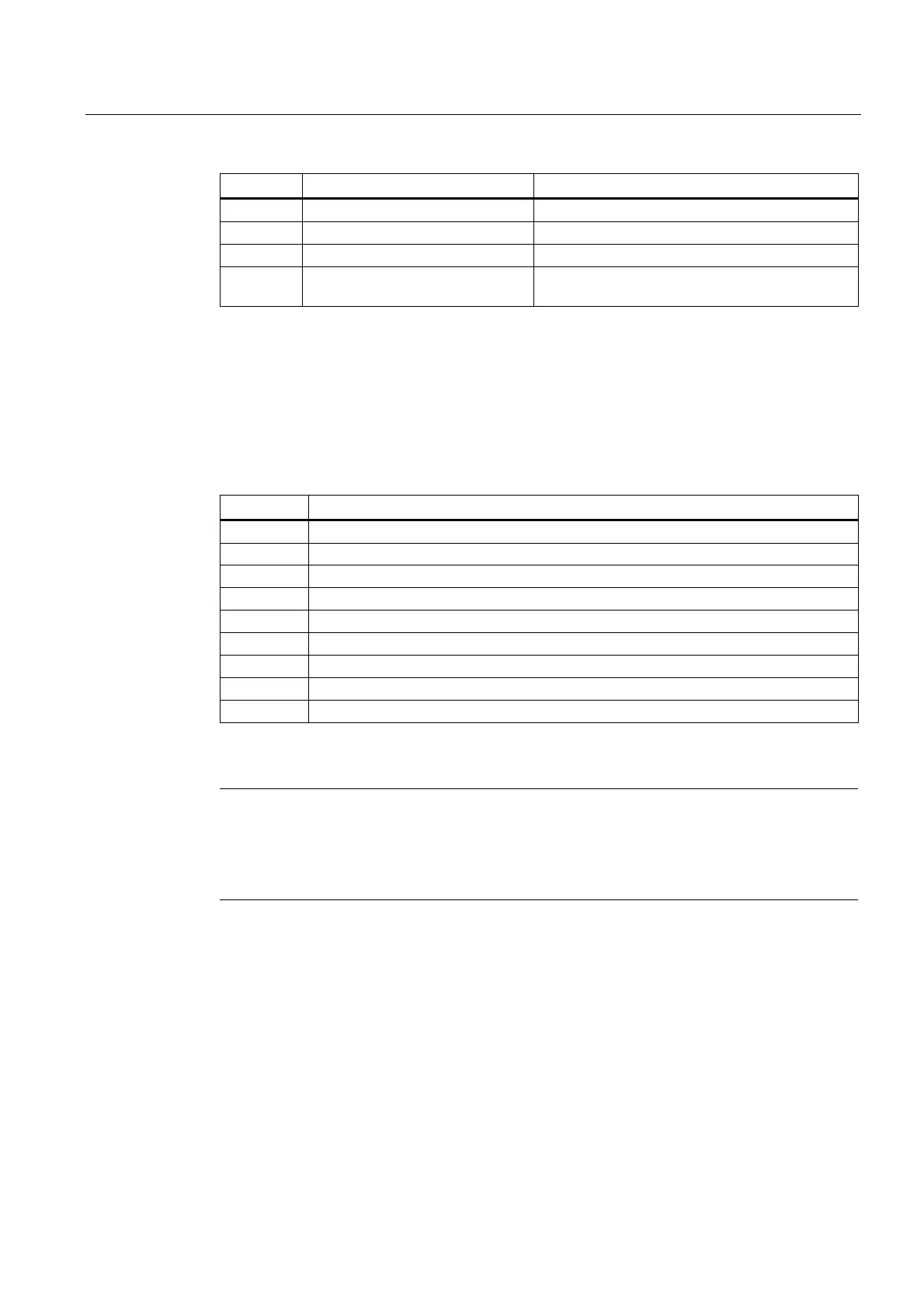

Type System variable Description

REAL $AC_MEAS_CORNER_ANGLE Calculated angle of intersection ϕ

REAL $AC_MEAS_DIAMETER Calculated diameter

REAL $AC_MEAS_TOOL_LENGTH Calculated tool length

REAL $AC_MEAS_RESULTS[10] Calculation results (depending on

$AC_MEAS_TYPE)

7.5.2.4 Calculation method

Activating the calculation

The calculation is activated by an HMI operator action with PI service _N_SETUDT. This Pl

service can accept one of the following parameter types:

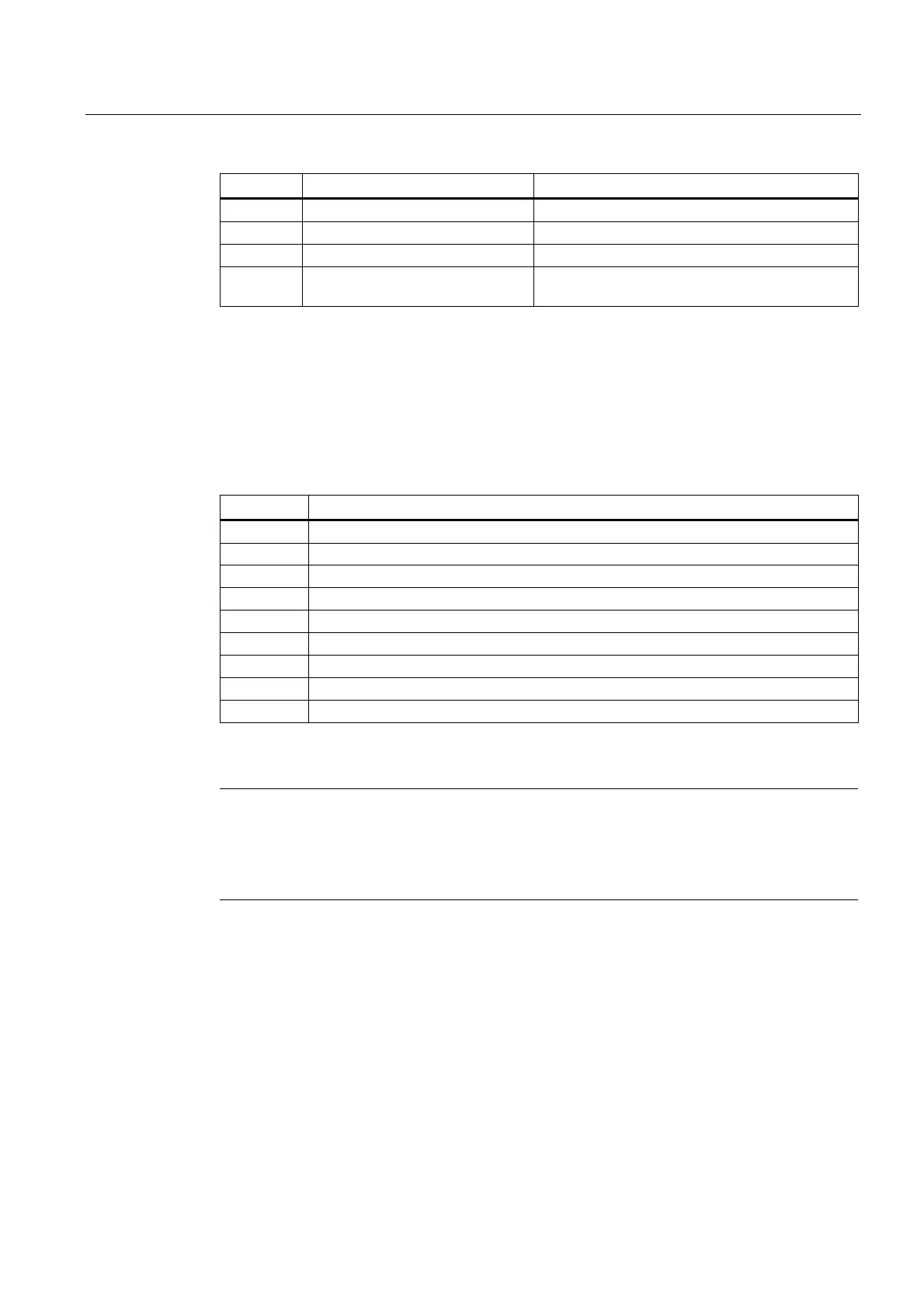

Type Meaning

1 Active tool offset

2 Active basic frames

3 Active settable frame

4 Global basic frames

5 Global settable frames

6 Calculate workpiece zero or tool lengths

7 Activate workpiece zero (write scratching)

8 Activate external work offset

9 Activate active tool carrier, TCOABS and PAROT

The change becomes apparent immediately in the reset state. In the stop state, the frame is

retracted at the next start.

Note

The PI service can be executed only in the reset and stop states. In the case of workpiece

measurement, the calculated frame is activated immediately with type no. 7. In the case of

tool measurement, the PI service must not be dispatched with type no. 7, since a zero point

does not have to be activated.

Activation in the Stop state

The new WCS positions are refreshed in the Stop state. With the continuation start on the

part program, the distance-to-go of the interrupted block is deleted. Traversal is made from

the current position to the end point of the next block.

Therefore, it is also possible in the Stop state to start a spindle in the MDA mode or in the

part program and set and scratch an actual value with M0. Another measurement can also

be performed.

Loading...

Loading...