N4: Own channel - only 840D sl

9.2 Stroke control

Extended Functions

558 Function Manual, 03/2013, 6FC5397-1BP40-3BA1

9.2.3 Criteria for stroke initiation

Initiate a stroke

The stroke initiation must be set, at the earliest, for the point in time at which it can be

guaranteed that the axes have reached a standstill. This ensures that at the instant of

punching, there is absolutely no relative movement between the punch and the metal sheet

in the machining plane.

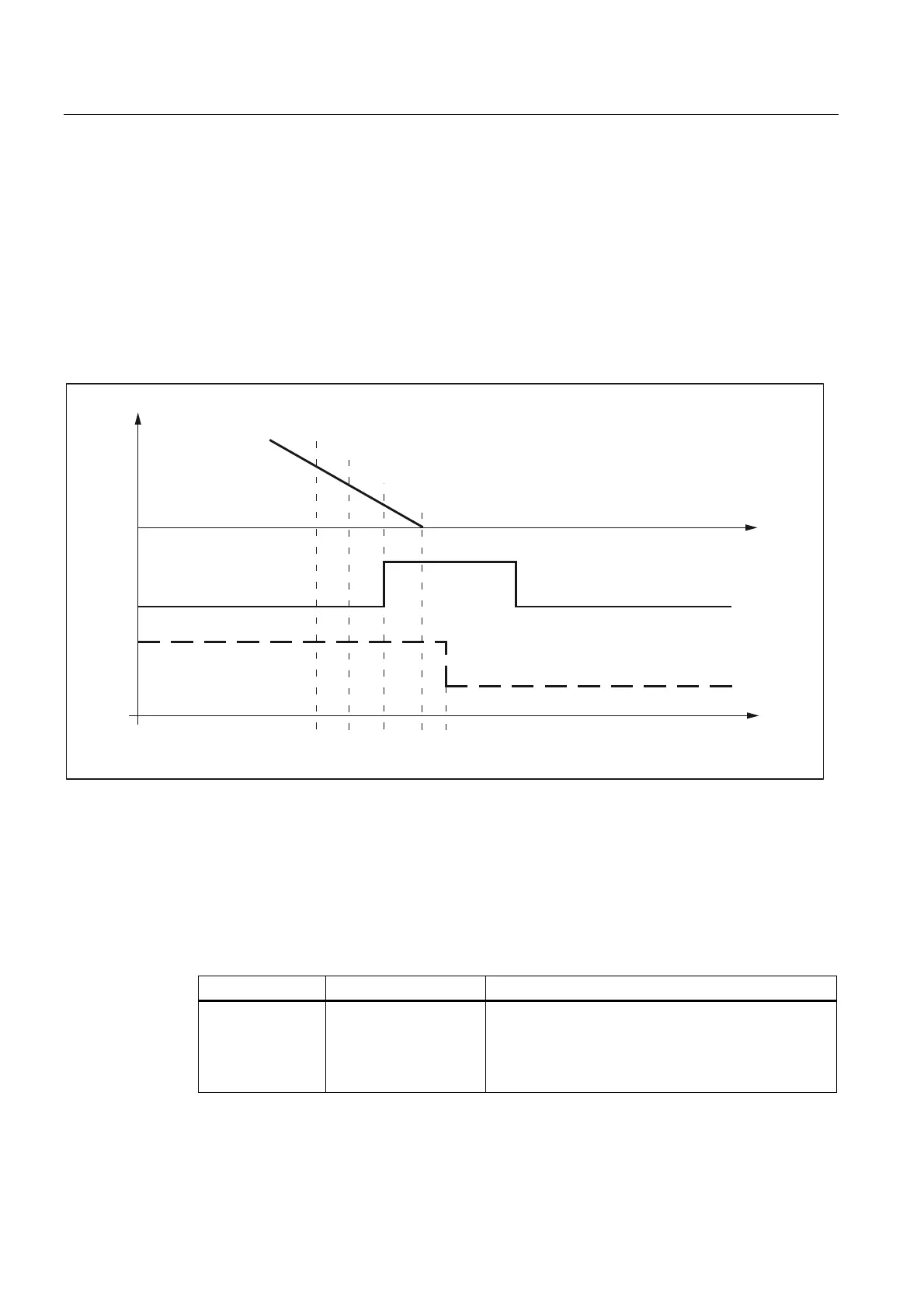

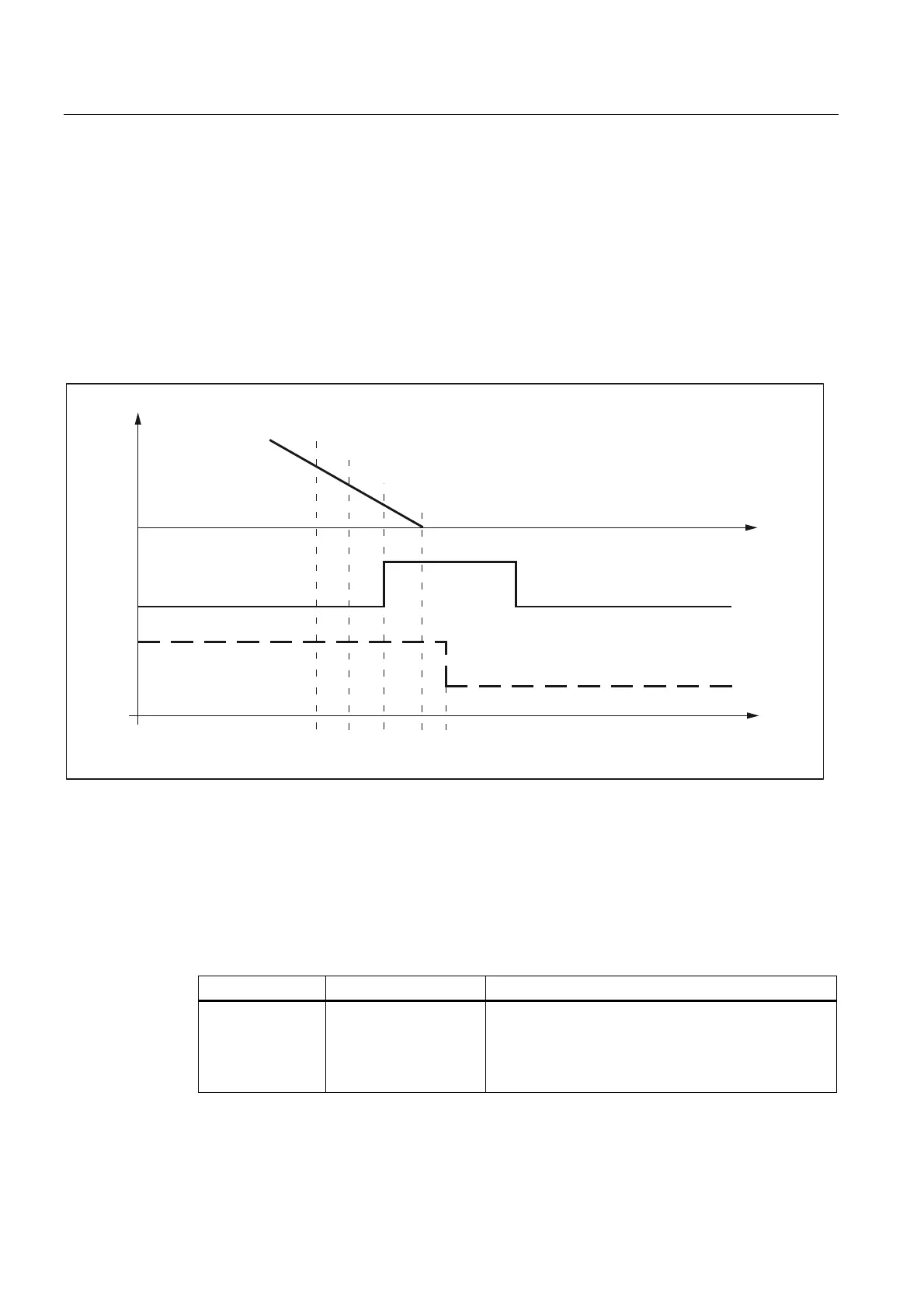

The following diagram shows the various criteria that can be applied to stroke initiation.

([DFWVWRSILQH

([DFWVWRSFRDUVH

(QGRILQWHUSRODWLRQ

,

$

W

W

W

W

W

W

Figure 9-2 Signal chart: Criteria for stroke initiation

The time interval between t

1

and t

2

is determined by the reaction of the punching unit to

setting of output A

0

. This cannot be altered, but can be utilized as a lead time for minimizing

dead times.

The diagram above shows the default setting with which the output is set when the "Exact

stop fine window" is reached (

G601; default setting of G group 12). The punch initiation times

t''

1

and t'

1

are programmed by means of G602 and G603 (see table below).

Programming Activation Description

G603

Stop interpolation The interpolation reaches the block end. In this case,

the axes continue to move until the overtravel has

been traversed, i.e. the signal is output at an

appreciable interval before the axes have reached

zero speed (see t"

1

).

Loading...

Loading...