W4: Grinding-specific tool offset and tool monitoring

17.1 Tool offset for grinding operations

Extended Functions

806 Function Manual, 03/2013, 6FC5397-1BP40-3BA1

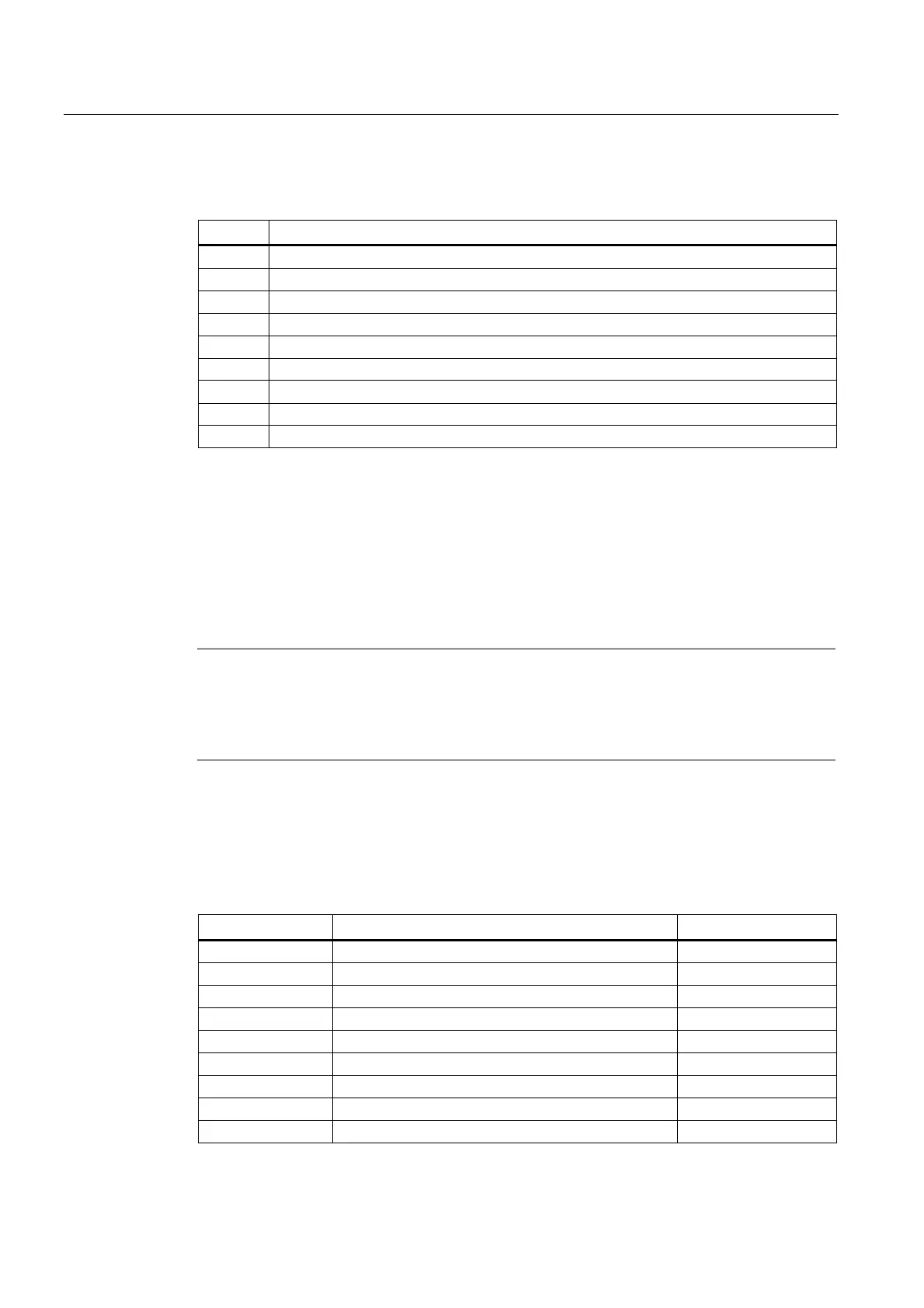

This structure can be used to create the following tool types:

Type Description

400 Surface grinding wheel

401 Surface grinding wheel with monitoring with tool base dimension for GWPS

402 Surface grinding wheel without monitoring without tool base dimension for GWPS

403 Surface grinding wheel with monitoring without tool base dimension for GWPS

410 Facing wheel

411 Facing wheel with monitoring with tool base dimension for GWPS

412 Facing grinding wheel without monitoring without tool base dimension for GWPS

413 Facing wheel with monitoring without tool base dimension for GWPS

490 Dresser

17.1.3 Tool-specific grinding data

Tool-specific grinding data

Tool-specific grinding data is available once for every T number (type 400- 499). The data is

automatically set up with every new grinding tool (type 400 - 499).

Note

Tool-specific grinding data has the same characteristics as a tool edge.

This is to be taken into account when the number of cuts is specified:

MD18100 $MN_MM_NUM_CUTTING_EDGES_IN_TOA

When all the cutting edges of a tool are deleted, the existing tool-specific grinding data is

deleted at the same time.

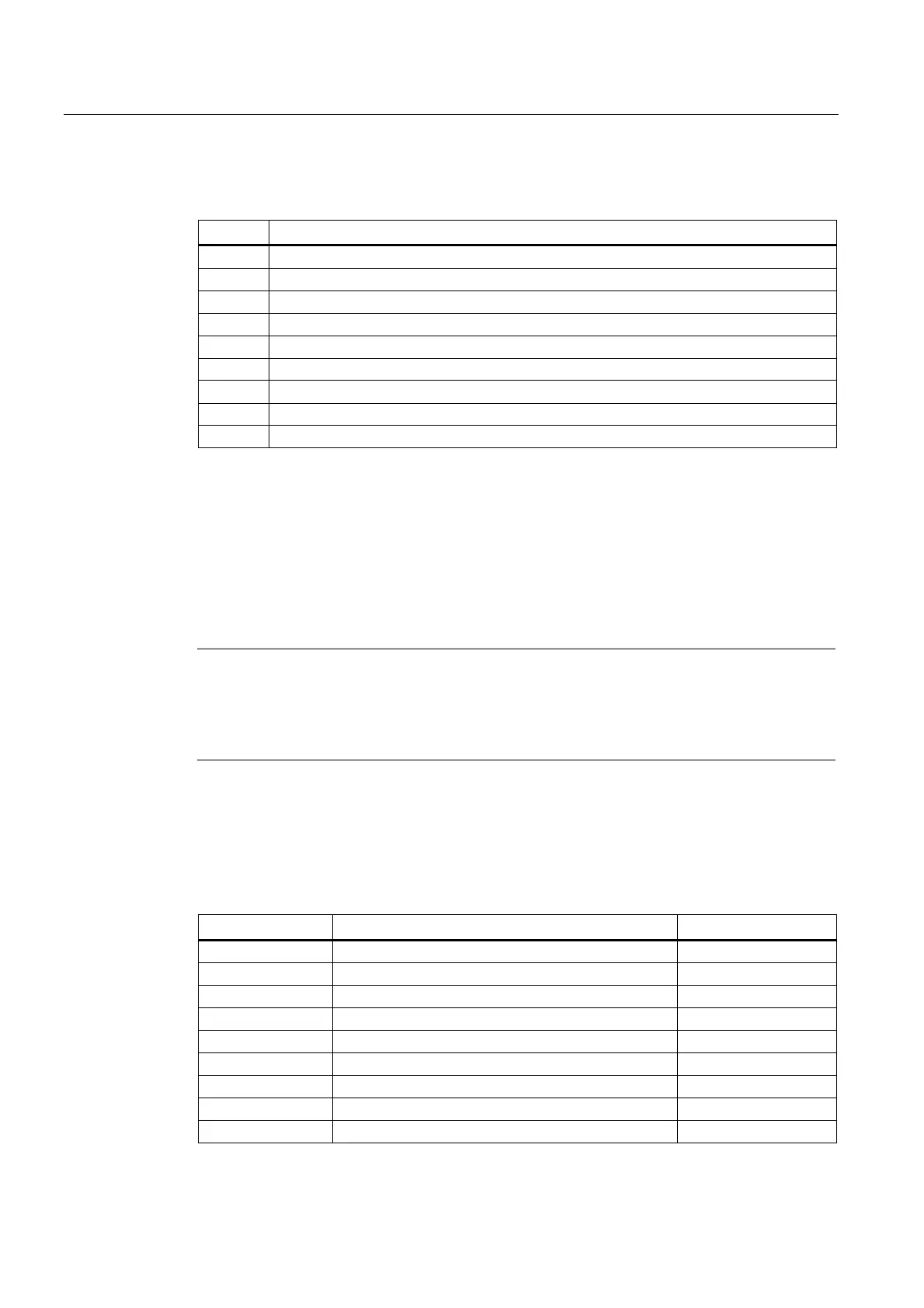

Parameters

The parameters are assigned as follows:

Parameter Meaning Data type

$TC_TPG1 Spindle number Integer

$TC_TPG2 Chaining rule Integer

$TC_TPG3 Minimum wheel radius Real

$TC_TPG4 Minimum wheel width Real

$TC_TPG5 Current wheel width Real

$TC_TPG6 Maximum speed Real

$TC_TPG7 Maximum peripheral speed Real

$TC_TPG8 Angle of inclined wheel Real

$TC_TPG9 Parameter number for radius calculation Integer

Loading...

Loading...