W4: Grinding-specific tool offset and tool monitoring

17.1 Tool offset for grinding operations

Extended Functions

Function Manual, 03/2013, 6FC5397-1BP40-3BA1

807

Parameter Meaning Data type

Additional parameters (user-specific cutting edge data)

$TC_TPC1

to

$TC_TPC10

Real

Definition of additional parameters $TC_DPC1...10

For the user-specific cutting data the additional parameters $TC_DPC1 to $TC_DPC10 can

be implemented independent of the WZ-type. This is done via the general machine data:

MD18096 $MN_MM_NUM_CC_TDA_PARAM

CAUTION

Data loss

Changes to MD18096 take effect after power on and will lead to initialization of the

memory.

A data backup must be created beforehand.

Spindle number $TC_TPG1

Number of the programmed spindle (e.g. grinding wheel peripheral speed) and spindle to be

monitored (e.g. wheel radius and width)

Chain rule $TC_TPG2

This parameter is set to define which tool parameters of tool edge 2 (D2) and tool edge 1 (D1)

have to be chained to one another. When the setpoint of a chained parameter is modified,

the value of the parameter with which it is chained is modified automatically.

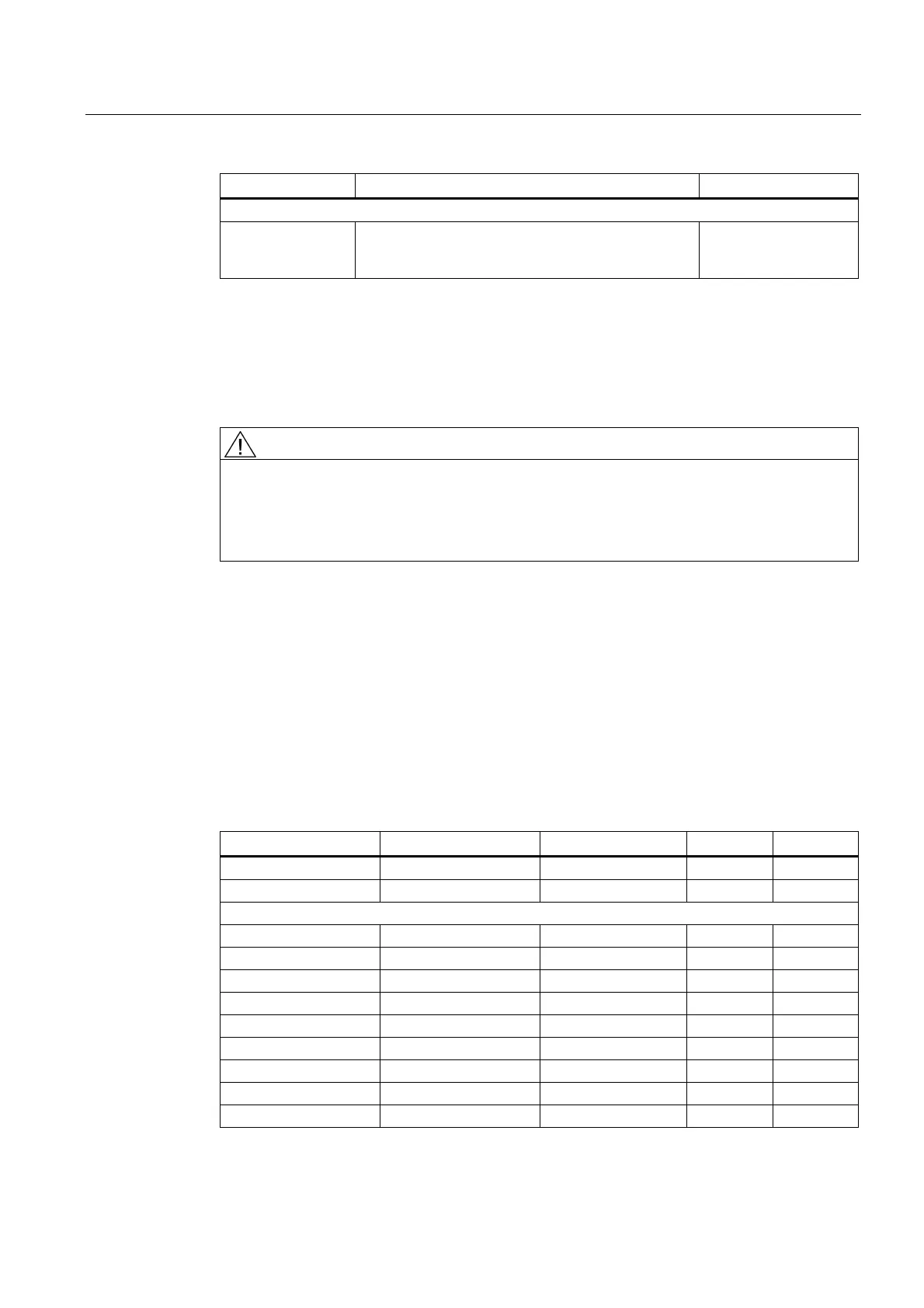

Tool parameter Meaning Bit in $TC_TPG2 Hex Dec

$TC_DP1 Tool type 0 0001 1

$TC_DP2 Length of cutting edge 1 0002 2

Geometry tool length compensation

$TC_DP3 Length 1 2 0004 8

$TC_DP4 Length 2 3 0008 16

$TC_DP5 Length 3 4 0010 32

$TC_DP6 Radius 5 0020 64

$TC_DP7 Reserved 6 0040 128

$TC_DP8 7 0080 256

$TC_DP9 8 0100 512

$TC_DP10 9 0200 1024

$TC_DP11 Reserved 10 0400 2048

Loading...

Loading...