W4: Grinding-specific tool offset and tool monitoring

17.1 Tool offset for grinding operations

Extended Functions

Function Manual, 03/2013, 6FC5397-1BP40-3BA1

805

Definition of additional parameters $TC_DPC1...10

For user-specific cutting edge data, additional parameters $TC_DPC1 to 10 can be set up

independent of the tool type using the following general machine data:

MD18096 $MN_MM_NUM_CC_TOA_PARAM

CAUTION

Data loss

Changes to MD18096 take effect after power on and will lead to initialization of the

memory.

A data backup must be created beforehand.

CAUTION

No grinding wheel offset changeover

Automatic changeover between grinding wheel offset left and right does not take place

during contour grinding.

A changeover must be programmed.

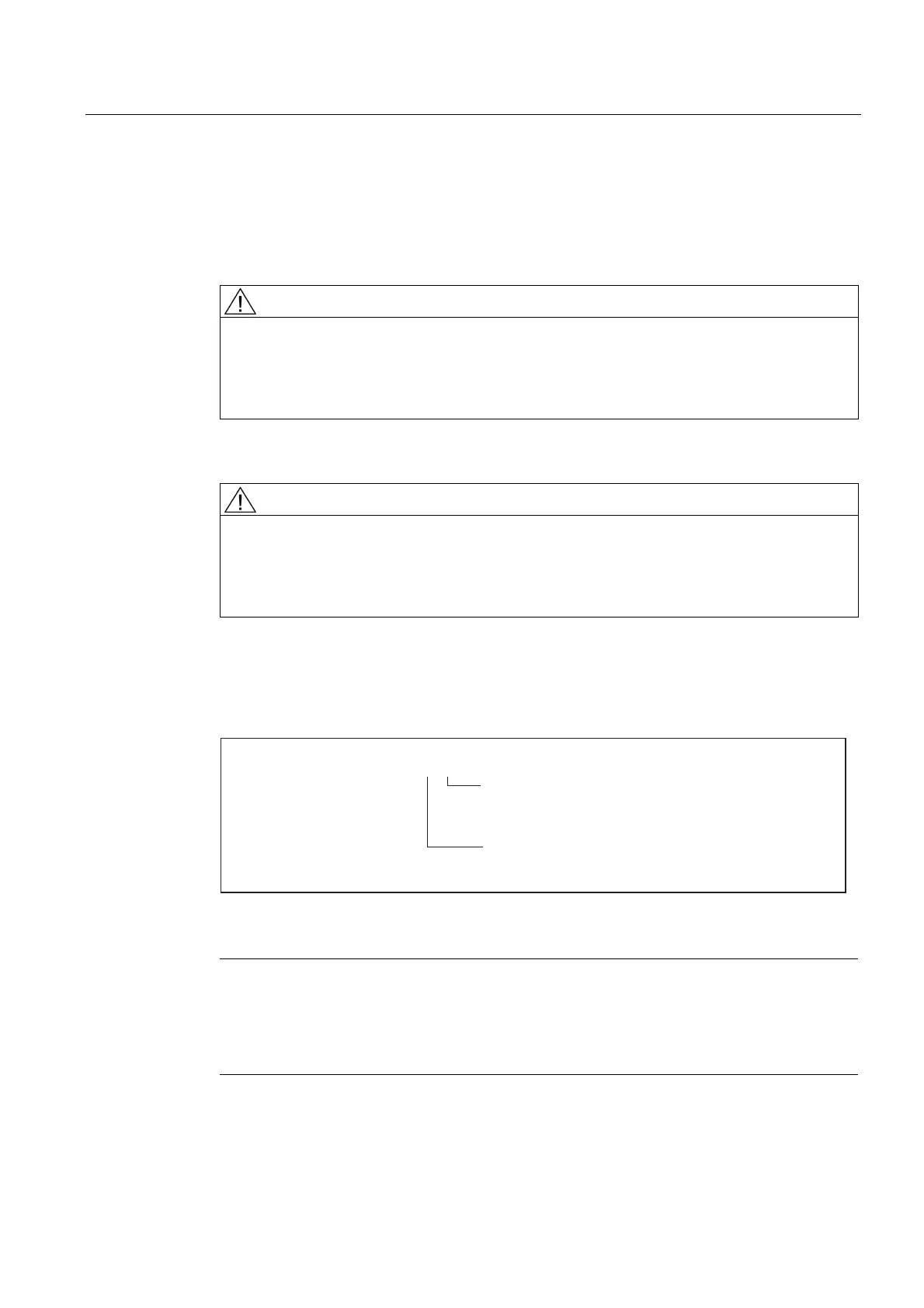

Tool types for grinding tools

The structure of tool types for grinding tools is as follows:

7RROW\SH

:LWKRXWPRQLWZLWKEDVHGLPIRU*:36

:LWKPRQLWZLWKEDVHGLPIRU*:36

:LWKRXWPRQLWZLWKRXWEDVHGLPIRU*:36

:LWKPRQLWZLWKRXWEDVHGLPIRU*:36

6XUIDFHJULQGLQJZKHHO

)DFLQJZKHHO

'UHVVHU

;<

Figure 17-2 Structure of tool type for grinding tools

Note

MD20350 $MC_TOOL_GRIND_AUTO_TMON

Through this channel-specific machine data it can be determined, whether for grinding tools

with monitoring (i.e. uneven tool types) the monitoring is already active or not when this tool

is selected.

Loading...

Loading...