M5: Measurement

7.5 Setting zeros, workpiece measuring and tool measuring

Extended Functions

Function Manual, 03/2013, 6FC5397-1BP40-3BA1

463

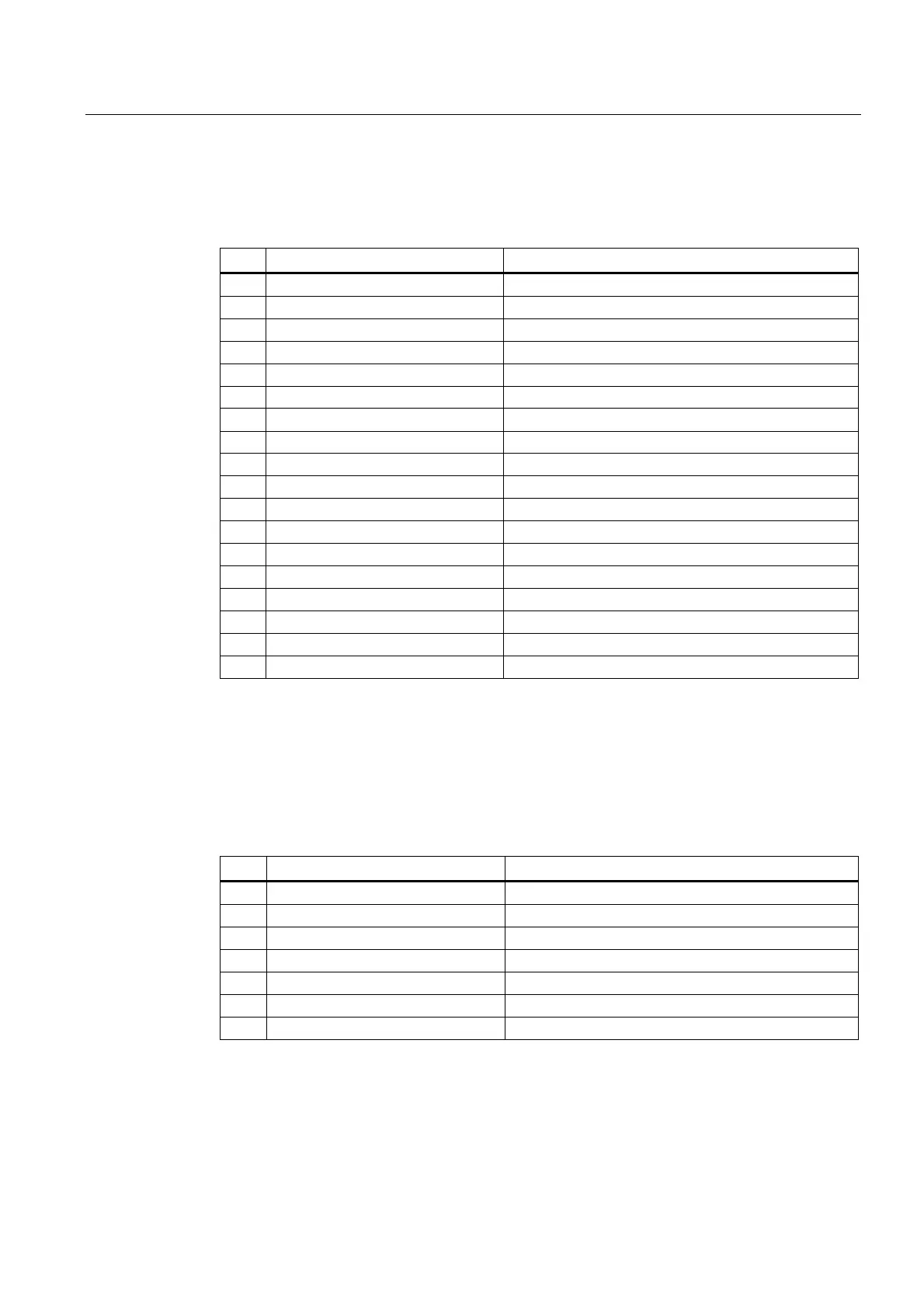

The following return values are output via the pre-defined MEASURE() function:

Table 7- 5 Predefined error messages

No. Return values Meaning

0 MEAS_OK Correct calculation

1 MEAS_NO_TYPE Type not specified

2 MEAS_TOOL_ERROR Error determining the tool

3 MEAS_NO_POINT1 Measuring point 1 does not exist

4 MEAS_NO_POINT2 Measuring point 2 does not exist

5 MEAS_NO_POINT3 Measuring point 3 does not exist

6 MEAS_NO_POINT4 Measuring point 4 does not exist

7 MEAS_NO_SPECPOINT No reference point available

8 MEAS_NO_DIR No approach direction

9 MEAS_EQUAL_POINTS Measuring points are identical

10 MEAS_WRONG_ALPHA Alpha α is wrong

11 MEAS_WRONG_PHI Phi ϕ is wrong

12 MEAS_WRONG_DIR Wrong approach direction

13 MEAS_NO_CROSSING Lines do not intersect

14 MEAS_NO_PLANE Planes do not exist

15 MEAS_WRONG_FRAME No frame or incorrect frame selected

16 MEAS_NO_MEMORY Insufficient memory available

17 MEAS_INTERNAL_ERROR Internal error

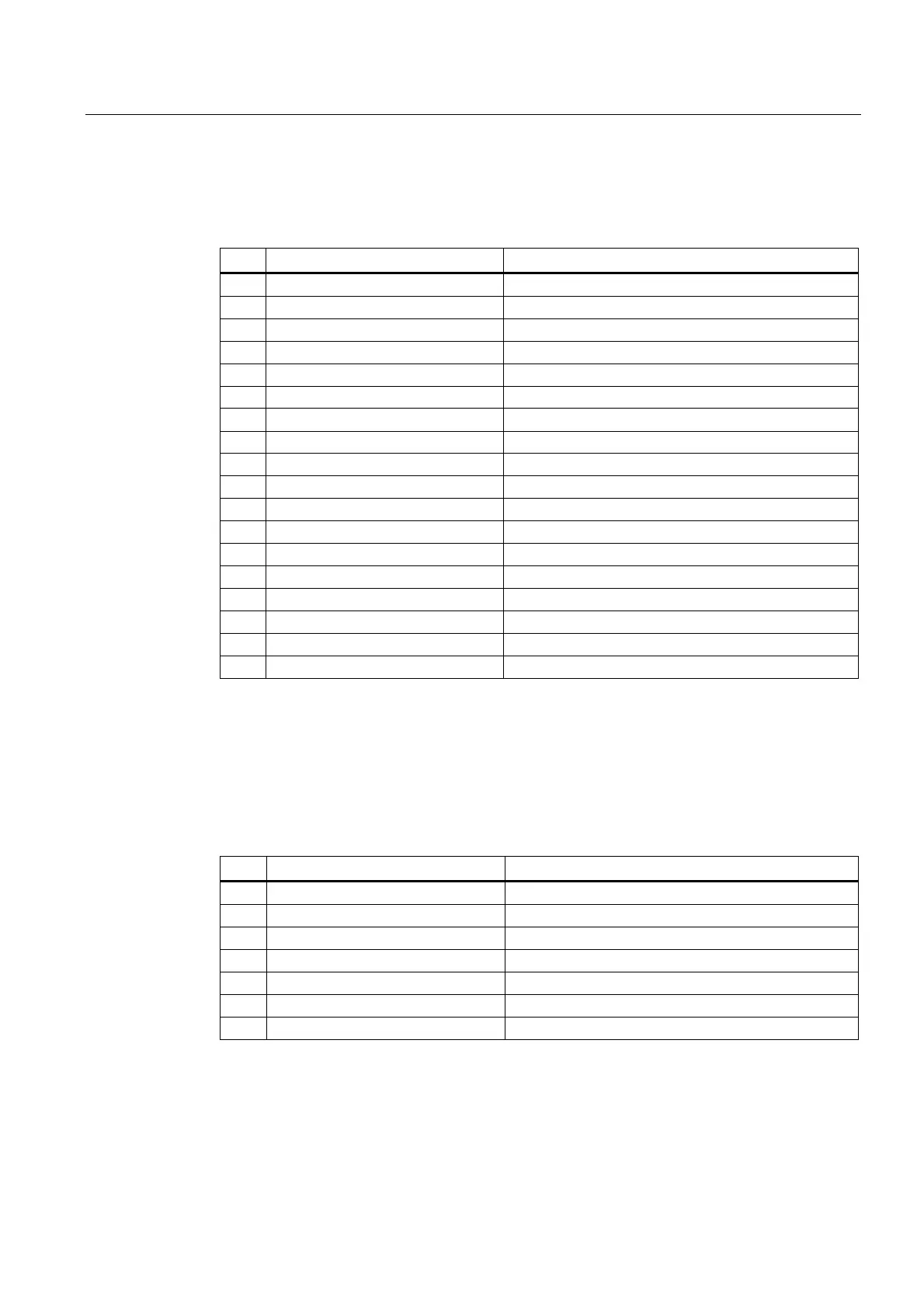

Tool measurement error

In the case of error code MEAS_TOOL_ERROR or EX_ERR_PI_REJ_MEASTOOLERROR,

the system stores a more detailed specification of the error with the following values in

output variable $AC_MEAS_TOOL_LENGTH:

Table 7- 6 Predefined error messages for MEAS_TOOL_ERROR

No. Return values Meaning

1 TOOL_NO_BLOCK No block available for the tool calculation

2 TOOL_WRONG_T_NUMBER Wrong T number

3 TOOL_WRONG_D_NUMBER Wrong D number

4 TOOL_EVAL_WRONG_TYPE The tool does not exist

5 TOOL_NO_TOOLCORR_BODY Memory problem

6 TOOL_DATA_READ_ERROR Error reading the tool data

7 TOOL_NO_TOOL_WITH_TRAFO No tool is selected with an active transformation

Loading...

Loading...