S3: Synchronous spindle

13.4 Points to note

Extended Functions

Function Manual, 03/2013, 6FC5397-1BP40-3BA1

739

Program code Comment

N05 G4 F1;

N10 COUPDEF(S2,S1,-1) ; Coupling factor -1:1

N11 COUPON(S2,S1) ; Activate coupling, the speed of following spindle S2

; results from the speed of the main spindle S1 and

; the coupling factor

N26 M2=3 S2=100 ; Programming of the speed difference,

; S2 is the following spindle

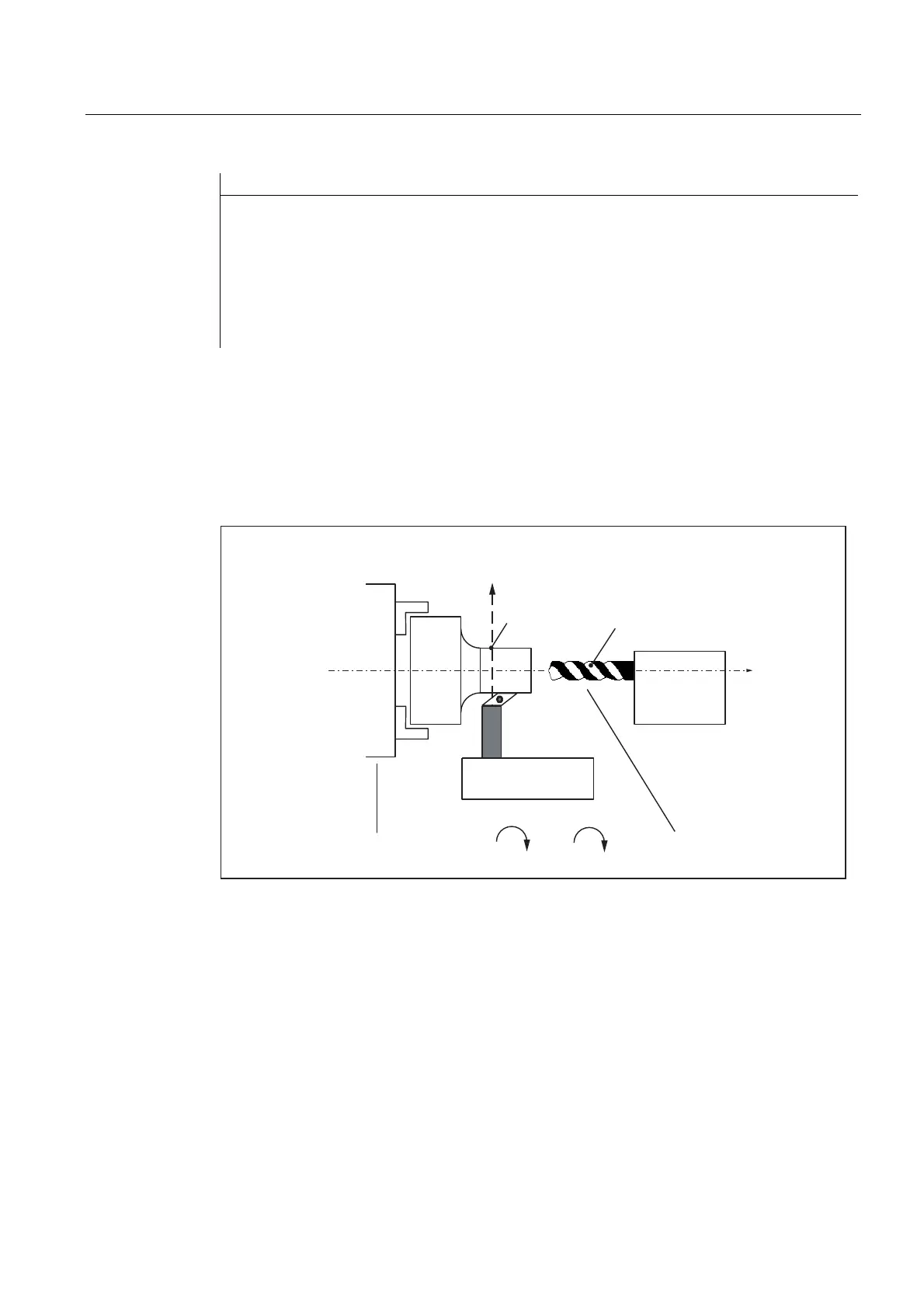

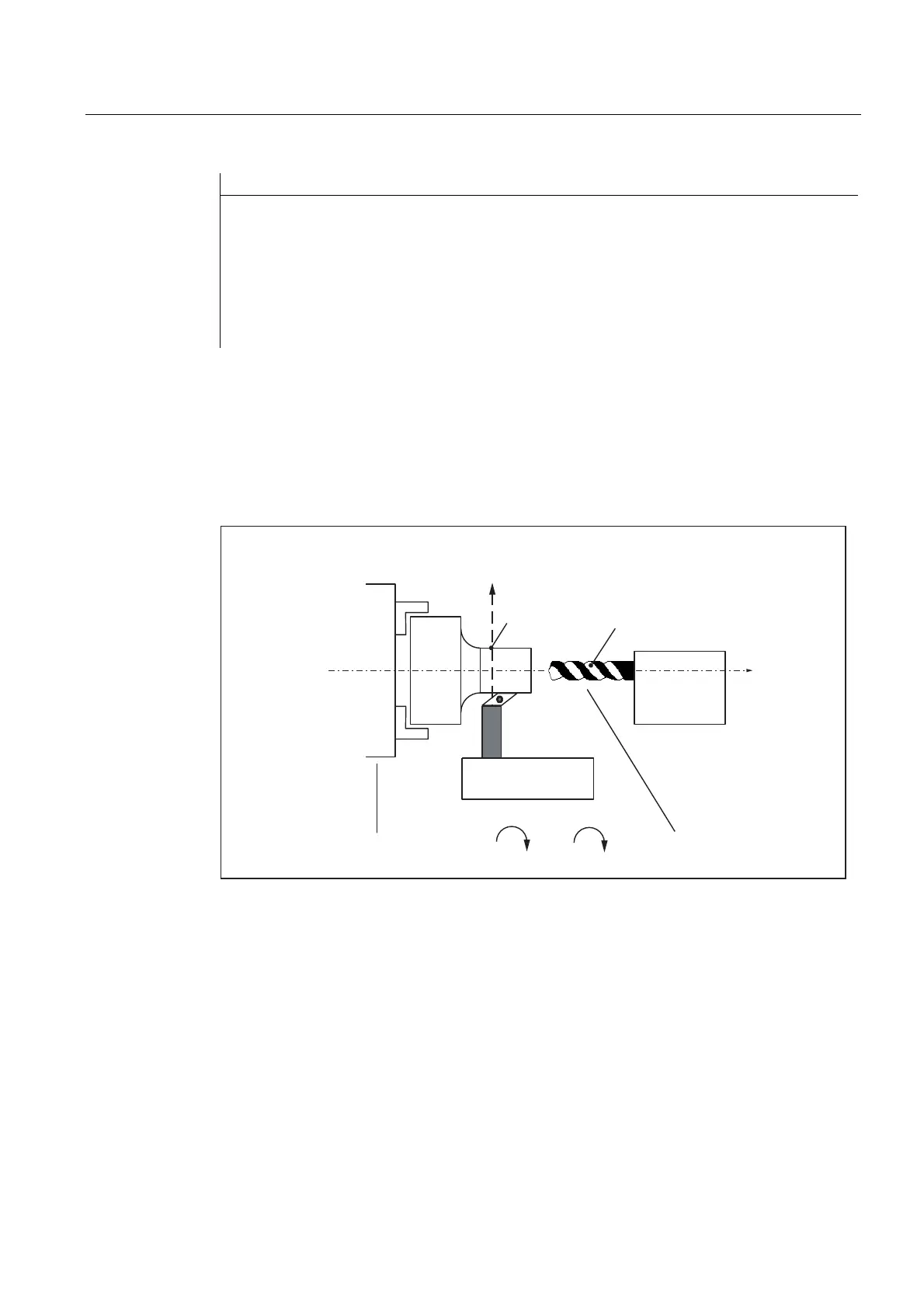

Application

Manufacturing operations with positioned leading spindle and rotating tools require exact

synchronism with the counter spindle which then functions like a following spindle. A turret

rotating about the following spindle allows parts to be machined with different tool types. The

following diagram shows an application in which the tool is positioned parallel to the main

spindle.

6OLGH

7XUQLQJWRRO

;

=

Q

Q

)ROORZLQJVSLQGOH/HDGVSLQGOH

:RUNSLHFH 7RRO

5HYROYHU

0DLQVSLQGOHZLWKZRUNSLHFH

&KXFN

&RXQWHUVSLQGOHZLWKGULYHQ

WRROLQUHYROYHU

Figure 13-5 Application on a single-slide turning machine with turret about Z axis

Requirements

Basic requirements for differential speed programming:

● Synchronous spindle functionality is required.

● The dynamic response of the following spindle must be at least as high as that of the

leading spindle. Otherwise, the system may suffer from reduced quality, for example, rigid

tapping without a compensating chuck G331/G332.

Loading...

Loading...