214323 63 Revision A

Table 3.6 Float Settings

Header Size

Torque Settings

Cutting on Ground Cutting off Ground

9.1 m (30 ft.) 1-1/2 to 2 2 to 2-1/2

10.6 m (35 ft.) 1-1/2 to 2 2 to 2-1/2

12.2 m (40 ft.) 2 to 2-1/2 2-1/2 to 3

13.7 m (45 ft.) 2 to 2-1/2 2-1/2 to 3

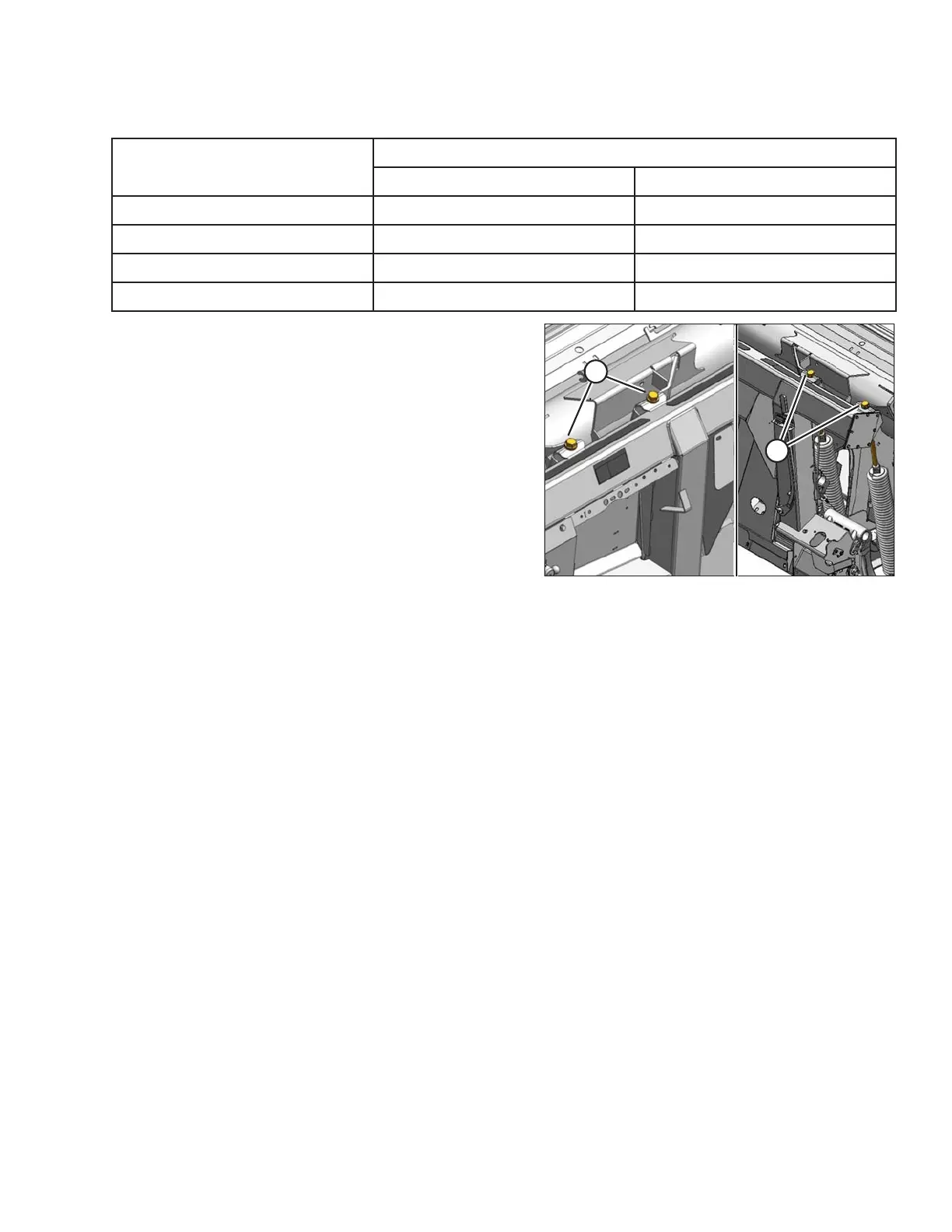

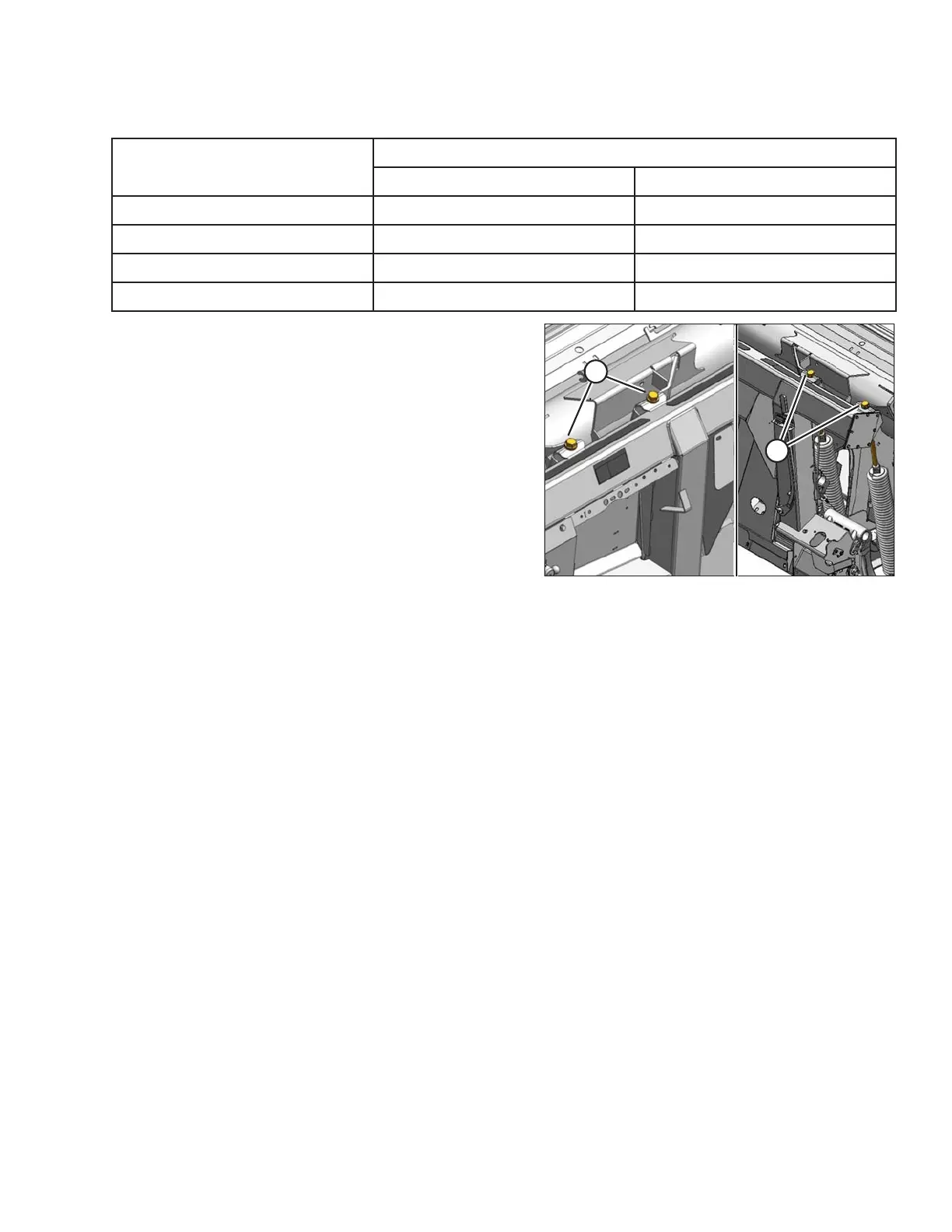

Figure 3.44: Float Adjustment

14. To increase float (decrease header weight)

a. Loosen jam nuts.

b. Turn left adjustment bolts (A) and right adjustment

bolts (B) clockwise.

c. Tighten jam nuts.

15. To decrease float (increase header weight)

a. Loosen jam nuts.

b. Turn left adjustment bolts (A) and right adjustment

bolts (B) counterclockwise.

c. Tighten jam nuts.

16. Use following guidelines when adjusting float:

• Adjust float so wrench readings are equal on both sides of the header.

• For 40- and 45-foot double-knife headers: adjust float so wrench readings are equal at both sides, and

then loosen both right spring bolts two turns.

• Turn each bolt pair equal amounts. Refer to Step 12, page 62, and repeat torque wrench

reading procedure.

• Set header float as light as possible without causing excessive bouncing to prevent knife component

breakage, soil scooping, or soil build-up at cutterbar in wet conditions.

• Use a slower ground speed with a light float setting, if necessary, to avoid excessive bouncing and leaving a

ragged cut.

• Use stabilizer wheels in conjunction with header float to minimize bouncing at header ends and to control

cut height when cutting off ground. Refer to 3.7.1 Cutting Height, page 53.

NOTE:

If adequate header float cannot be achieved using all of available adjustments, an optional heavy duty spring is

available. See your MacDon Dealer or refer to parts catalog for ordering information.

OPERATION

Loading...

Loading...